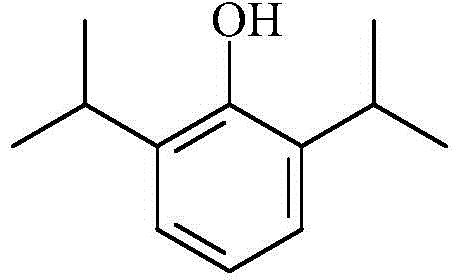

Formula and preparation method of non-allergenic and painless novel propofol fatty microemulsion freeze-drying preparation

A technology for propofol fat and freeze-dried preparations, applied in freeze-dried delivery, pharmaceutical formulations, anesthetics, etc., can solve problems such as chemical instability, and achieve the effects of reducing vascular irritation, preventing oxidative degradation, and stabilizing preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

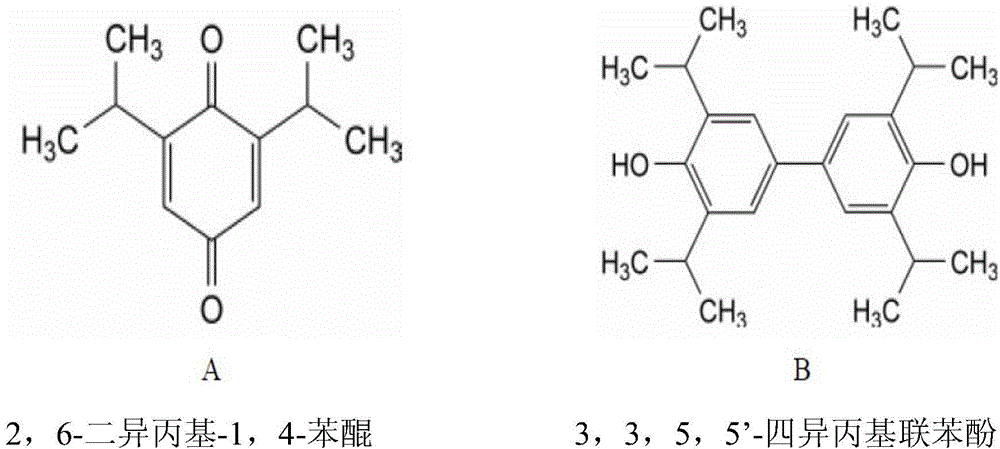

Problems solved by technology

Method used

Image

Examples

Embodiment 1

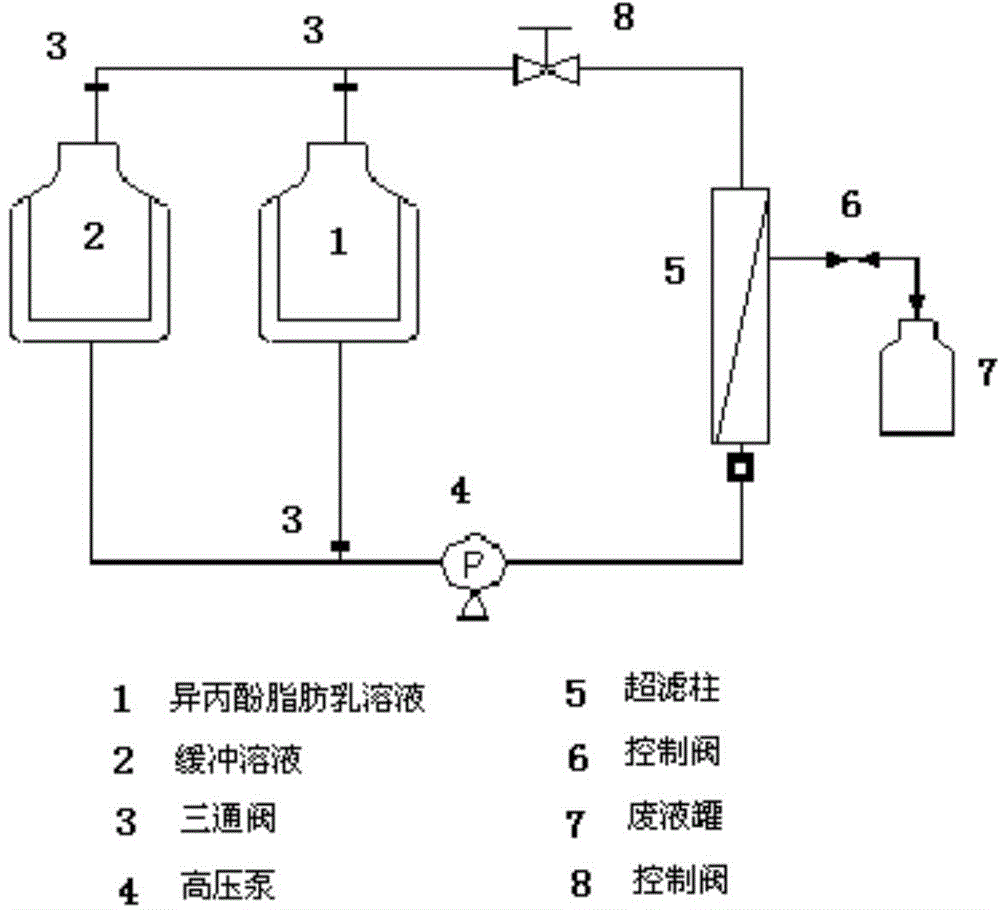

[0092] Example 1: Investigation on the applicability of ultrafiltration to common propofol fat microemulsion

[0093] Get the propofol fat microemulsion 1000mL that any embodiment prepares, get a small amount of sample analysis its water phase free propofol concentration. according to figure 2 Assemble the "ultrafiltration production equipment" and select the ultrafiltration cartridge with suitable pore size. The main factor in the selection is that the aqueous solution, especially the free propofol in the water phase, can pass freely, while the fat emulsion cannot pass through as the selection parameter. First, equilibrate the ultrafiltration column with isotonic buffer solution, then slowly input the propofol fat emulsion into the ultrafiltration column to adjust the column pressure. The aqueous solution containing free propofol passes through the ultrafiltration column and is effectively separated from the propofol fat microemulsion. The missing solution is replenished b...

Embodiment 2

[0094] Example 2: Investigation of the applicability of ultrafiltration to polyethylene glycol propofol fat microemulsion

[0095] Get according to the polyethylene glycol propofol fat microemulsion sample 1000mL prepared in embodiment 21-24, take a small amount and analyze its aqueous phase free propofol concentration. according to figure 2 Assemble the "ultrafiltration production equipment", select the ultrafiltration cartridge with the appropriate pore size, and use the water solution to pass through freely, but the fat emulsion cannot pass through as the selection parameter. First, equilibrate the ultrafiltration column with isotonic buffer solution, then slowly input the propofol fat emulsion into the ultrafiltration column to adjust the column pressure. The aqueous solution containing free propofol passes through the ultrafiltration column and is effectively separated from the propofol fat microemulsion. The missing solution is replenished by buffer solution. General...

Embodiment 3

[0100] Embodiment 3: the weight ratio of propofol and synthetic fatty acid glyceride is 1:12

[0101] prescription:

[0102]

[0103] Take 10.0 g of propofol and 120.0 g of glyceryl palmitate, add 12.5 g of phosphatidylcholine distearate, heat and stir for about 10-20 minutes and mix well. Another 700ml of water for injection was taken, and 22.0g of mannitol was added. Under nitrogen protection and stirring conditions, the propofol phospholipid oil solution was added to the mannitol aqueous solution, and the total amount was adjusted to 1000ml. Homogenize 7-8 times with a high-pressure homogenizer, the homogenization pressure is 100MPa, until the particle size is less than 180nm, adjust the pH to 6.0-8.0, filter, fill, and use a brown vial to prepare a freeze-dried preparation.

[0104] After the lyophilized preparation of propofol fat microemulsion prepared by the above method was reconstituted, the content of free propofol in the water phase was analyzed by ultracentrif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com