Production method of printing composite clothing material and printing composite clothing material

A production method and clothing technology, applied in the textile field, can solve the problems of repeated dry cleaning, poor anti-slip performance, and soft fabric texture, etc., and achieve good compatibility, sufficient adhesion fastness, and meet the effects of clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1: double-sided weft-knitted products.

[0068] According to product use and performance positioning, this type of printing product should have good anti-pilling and abrasion resistance, silky soft, smooth and fluffy feel, sufficient four-sided elasticity, adhesion fastness, and excellent washability. Considering that this type of product can replace lining and cloth, it can even be used as the front of printed fabric after compounding. The optimum square weight of the finished product of this kind of product is 40-85 grams per square meter. The yarn is selected from micro-net polyester low-stretch yarn 15-40D. Single jersey fabric, 26-34 inches in diameter, 34-44 needles / inch weaving machine.

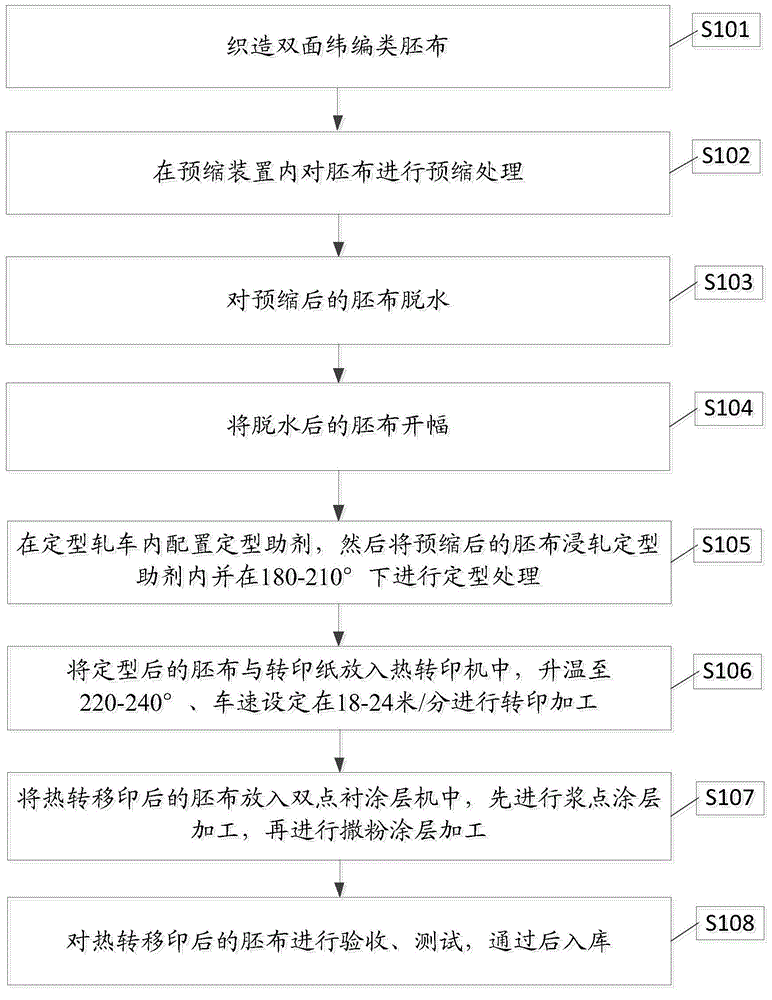

[0069] Specifically, for the production method of the double-sided weft-knitted printing composite clothing material in this embodiment such as figure 1 shown, including the following steps:

[0070] S101: Weaving double-sided weft-knitted gray fabric.

[0071] Th...

Embodiment 2

[0094] Embodiment two: pure warp knitting products.

[0095] Polyester FDY filament products have very good surface smoothness, especially the double-combed warp knitted fabric with 28-36 needles, which is also a common lining for high-end women's clothing. The raw material can be 20D-30D FDY polyester filament. In order to take into account the soft feel and the adhesion fastness after coating, the yarn F number (number of single fibers) is between 24-72. The production method of this type of product is different from the above-mentioned weft-knitted product except that the specific weaving process is different, and the rest of the process flow and process formula are roughly the same.

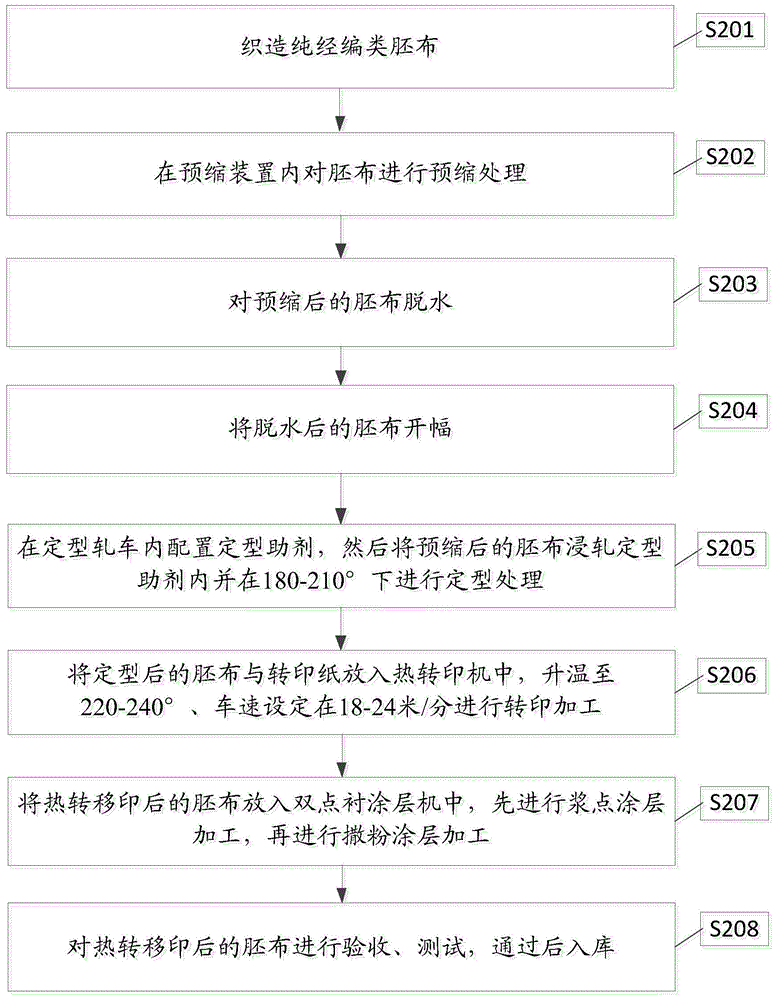

[0096] Specifically, for the production method of the double-sided weft-knitted printing composite clothing material in this embodiment, such as figure 2 shown, including the following steps:

[0097] S201: Weaving pure warp knitted gray cloth.

[0098] The specific weaving process of thi...

Embodiment 3

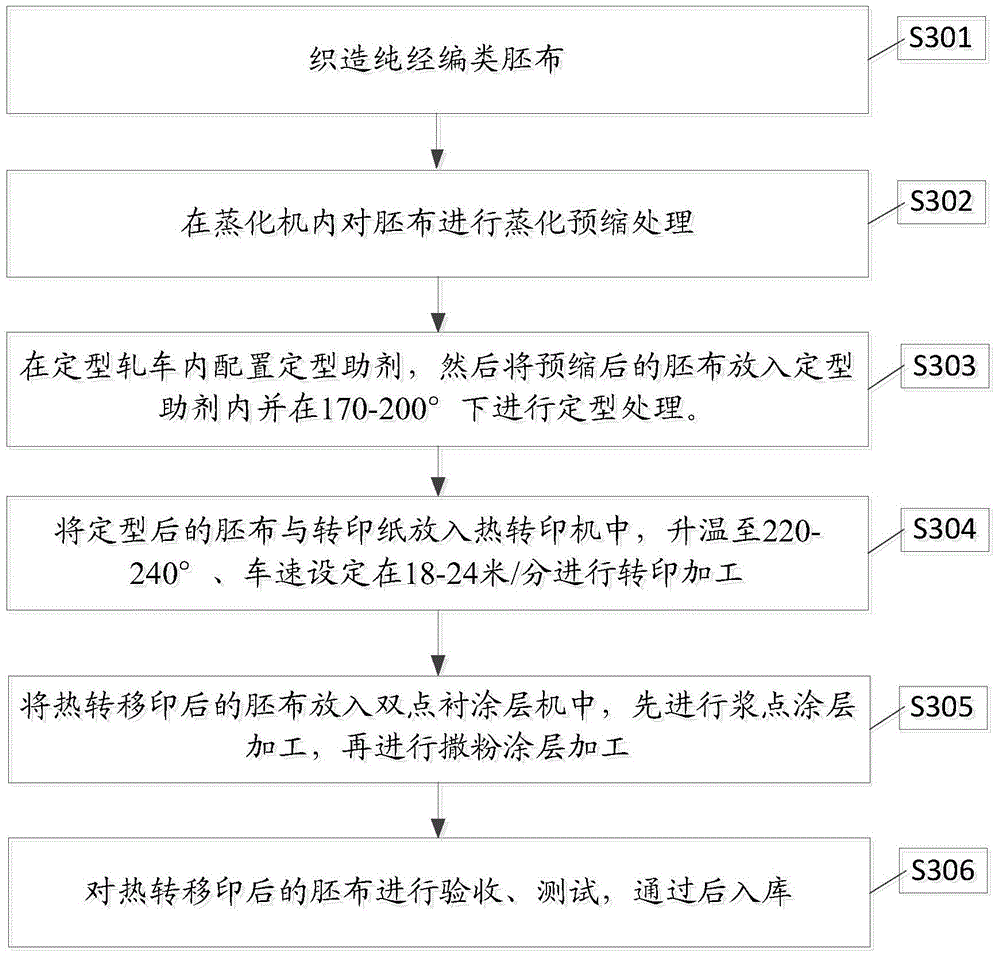

[0113] Preferably, the yarn can be changed to 20D / 24F FDY polyester filament to meet the requirements of lighter and thinner warp knitting and printing composite products. In addition, if a 32-needle 176-inch double-comb warp knitting machine is used for weaving, it is necessary to increase the weft density appropriately to improve the coating back through. The square gram weight of the base fabric is about 40-50 grams per square meter, and the coated product The weight is about 50-60 grams per square meter. Embodiment 3: warp knitting and weft inserting products.

[0114] The gray fabrics of the first two types of products are similar to ordinary down jacket weft-knitted fabrics and traditional warp-knitted linings, but their cost is high, the production process is more complicated, energy consumption and emissions are relatively high, but their finished products are very good in anti-pilling and abrasion resistance . Considering the balance of anti-pilling, abrasion resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com