A functional coating liquid and its application in cigarettes

A technology of functional and coating materials, applied to coated paper and its application in cigarettes, and the field of functional coating materials, which can solve the problems of low effective content of functional materials, flying powder, difficult operation, etc., and achieve Good promotion and application significance, good biocompatibility, and the effect of reducing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

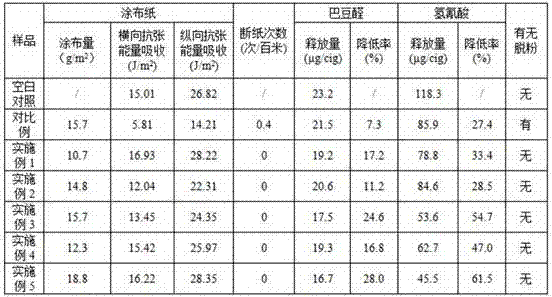

Examples

Embodiment 1

[0040] The functional coating liquid provided in this embodiment is prepared by the following steps:

[0041] (1) Swell polyvinyl alcohol in water and heat to dissolve, and add surfactant;

[0042] Described polyvinyl alcohol is PVA17-88 type; The mass concentration of described polyvinyl alcohol aqueous solution is 3%;

[0043] Described surfactant is lauroyl monoethanolamine; The massfraction of described surfactant is 0.3%;

[0044] (2) After adding amino acid and / or amino acid salt to the solution in step (1), stir at a high speed at a speed of 700r / min, stir for 15 minutes, then add diluent, continuously feed nitrogen, heat and stir to make a uniform Paper coating liquid can be;

[0045] The amino acid is proline, and the mass concentration after adding is 10%;

[0046] The amino acid salt is lysine sodium salt, and the mass concentration after adding is 15%;

[0047] The diluent is ethanol, and the mass concentration of ethanol is 30%.

[0048] The functional coatin...

Embodiment 2

[0055] The preparation process of the functional coating material liquid of this embodiment is the same as that of Example 1, only the polyvinyl alcohol is adjusted to PVA17-99 type; the mass concentration of the polyvinyl alcohol aqueous solution is 6%; the surfactant is lauroyl diethanolamine; the surface active The mass fraction of the agent is 0.2%; the amino acid is asparagine; the amino acid salt is arginine potassium salt; the mass concentration of the amino acid is 12%; the mass concentration of the amino acid salt is 15%; the diluent is water; the mass fraction is 10% .

[0056] Using the coating liquid prepared in this embodiment to prepare functional coated paper is the same as the comparative example, and the coating weight of the coated paper finally obtained is 14.8g / m 2 .

[0057] The preparation, detection and blank control of filter stick cigarettes are the same as the comparative example.

[0058] The experimental results showed that compared with the blank...

Embodiment 3

[0060] The preparation process of the functional coating material liquid of this embodiment is the same as that of Example 1, only adjusting polyvinyl alcohol to be PVA05-88 type; The mass concentration of polyvinyl alcohol aqueous solution is 10%; Surfactant is cocoyl diethanolamine; The mass fraction of the active agent is 0.1%; the amino acid salt is 15% lysine sodium salt and 17% arginine potassium salt respectively; the diluent is 1,2-propanediol; the mass concentration of the diluent is 10% %.

[0061] Using the coating liquid prepared in this embodiment to prepare functional coated paper is the same as the comparative example, and the coating weight of the coated paper finally obtained is 15.7g / m 2 .

[0062] The preparation, detection and blank control of filter stick cigarettes are the same as the comparative example.

[0063] The experimental results showed that compared with the blank control, the release of crotonaldehyde in mainstream cigarette smoke was reduced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com