Low density glass particles with low boron content

A glass particle and glass micro technology, applied in the directions of transportation, packaging, thin material handling, etc., can solve the problems of chemical-free durability and fragility, and achieve the effect of reducing glass waste and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0081] All parts, percentages, ratios, etc. in the examples and in the remainder of this specification are by weight unless otherwise indicated. Starting materials were purchased from Sigma Aldrich, St. Louis, Missouri unless otherwise noted.

[0082] The recyclable glass used in the examples was a tri-color recyclable container glass (80 mesh) available from Strategic Materials Inc (Strategic Materials Inc, Houston, Texas) in white (flint), amber and emerald green (green) recyclable glass blend composition.

[0083] testing method

[0084] Average particle density determination

[0085] According to ASTM D2840-69, "Average True Particle Density of Hollow Microspheres", using fully automated gas displacement obtained from Micromeritics, Norcross, Georgia Pycnometer ACCUPYC 1330 PYCNOMETER, to determine the density of microspheres.

[0086] particle size determination

[0087] Particle size distribution was determined using a BECKMAN COULTER LS 13 320 Particle Size A...

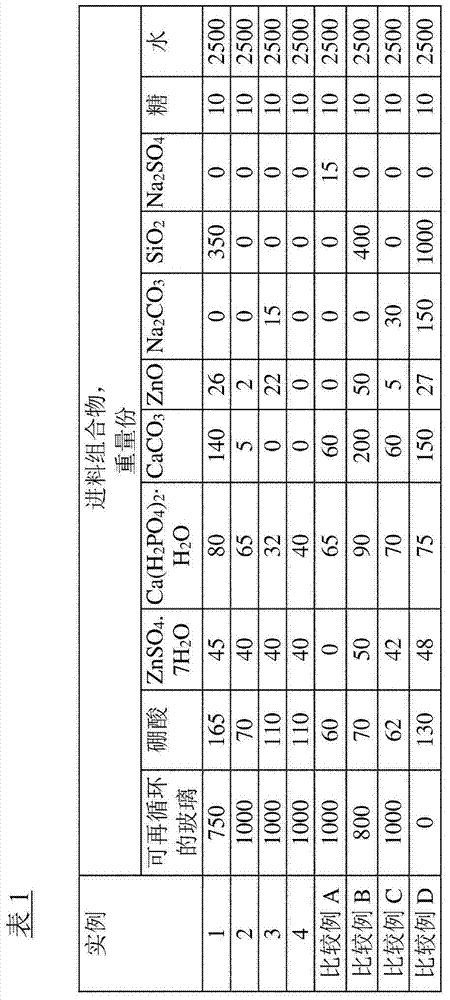

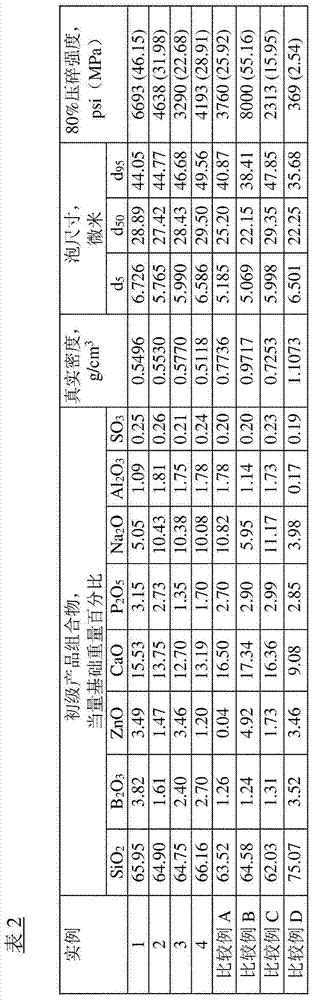

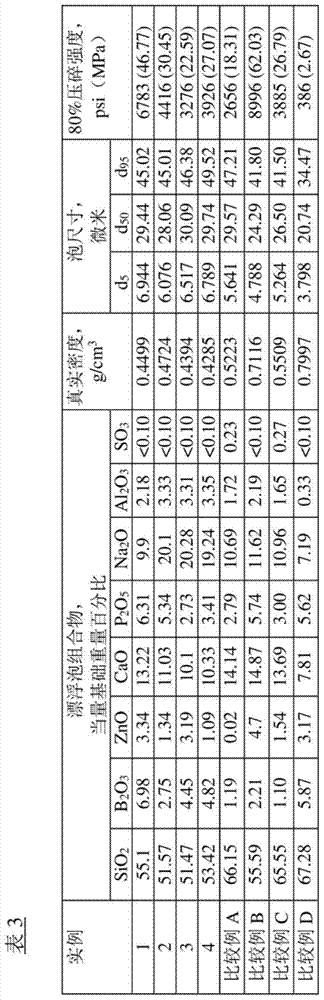

example 1-4 and comparative example A-D

[0095] Material :

[0096] Tricolor recyclable container glass (80 mesh) is commercially available from Strategic Materials Inc., Texas. On an equivalent basis, according to the chemical analysis method of hollow microspheres (above), the analysis result of the glass is, 2.07 weight percent Al 2 o 3 , 0.04% by weight of B 2 o 3 , 12.18% by weight of CaO, 13.49% by weight of Na 2 O, 0.02% P 2 o 5 , 0.27 weight percent SO 3 , 69.54 weight percent Si0 2 and 0.01 weight percent ZnO.

[0097] Boronic Acid: Commercially available from EMD Chemicals, Gibbstown, New Jersey.

[0098] Sugar: Available from Domino Food Inc., Yonkers, New York.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| crushing strength | aaaaa | aaaaa |

| crushing strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com