Method for improving copper precipitating and copper plating quality of PCB

A technology of PCB board and copper sinking, which is applied in the direction of liquid chemical plating, cleaning/polishing of conductive patterns, and formation of electrical connections of printed components, etc. It can solve problems such as excessive copper plating and blockage of through holes on PCB boards, and achieve Improve the uniformity of copper plating, avoid pollution, and improve the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

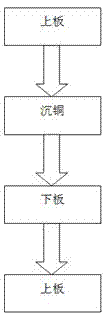

[0030] like figure 2 As shown, the present embodiment provides a method for improving the quality of copper sinking and copper plating of PCB boards. Clean, remove the loose copper layer left by the last copper sinking process attached to the sinking copper hanging basket, and then load the above PCB board to be sinking copper on the sinking copper hanging basket (upper board), and hang it with the sinking copper Basket together into the sinking copper potion for sinking copper, after sinking copper, remove the PCB board (lower board), clean the sinking copper hanging basket again, clean the copper particles and copper scraps on the sinking copper hanging basket, Then reload a new round of copper PCB boards to be sunk, and carry out the copper sinking work of the next round of PCB boards.

[0031]The method for improving the quality of copper sinking and copper plating on a PCB provided by this embodiment, by eliminating the main source of the above-mentioned copper particle...

Embodiment 2

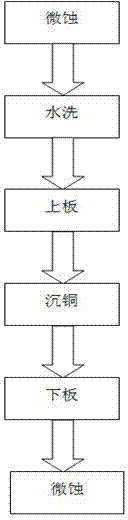

[0036] This embodiment provides a method for improving the quality of copper sinking and copper plating on a PCB board, which is a further improvement to Example 1. In this embodiment, a water washing step is added after the micro-etching step, and water is used to remove the micro-etched sinker. The copper hanging basket should be washed with water to prevent the micro-etching liquid remaining on the copper sinking basket from contaminating the copper sinking potion in the copper sinking tank.

[0037] In the water washing step, first lift the copper sinking basket with the clean and crisp copper layer out of the cleaning tank, rinse it with tap water, and rinse it for 2 to 3 minutes at a flow rate of 10 to 20 lpm, then the remaining copper sinking basket can be removed. After the cleaning solution is rinsed clean, it can meet the requirement that the copper sinking PCB can be loaded without contaminating the copper sinking solution. The above tap water can also be replaced w...

Embodiment 3

[0039] Before the PCB board to be immersed copper enters the copper immersion process, it usually needs to be cleaned to remove impurities such as oil, dust, and debris attached to it. In factory automation and semi-automatic production, a program is usually set to control the immersion of the copper-immersed PCB into the micro-etching solution in the micro-etching tank. presented in the etched cylinder.

[0040] This embodiment is an improvement on the basis of Embodiment 1 or 2. The difference is that: this embodiment does not have a cleaning tank and cleaning solution specially used for cleaning the crispy copper layer, but uses the original cleaning solution for the PCB board to be immersed copper. Micro-etching cylinder and micro-etching liquid instead. This is because the above-mentioned micro-etching solution is prepared from sodium persulfate and sulfuric acid in a ratio of 1.5:1, wherein the concentration of the sodium persulfate is 50g / L, the concentration of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com