Organic electroluminescent device and preparation method thereof

An electroluminescent device, organic technology, applied in the direction of electric solid device, semiconductor/solid state device manufacturing, electrical components, etc., to achieve the effect of prolonging the life of the device, improving the barrier performance, and excellent packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

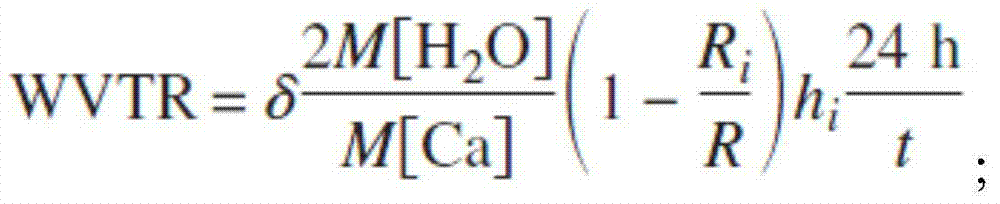

Examples

Embodiment 1

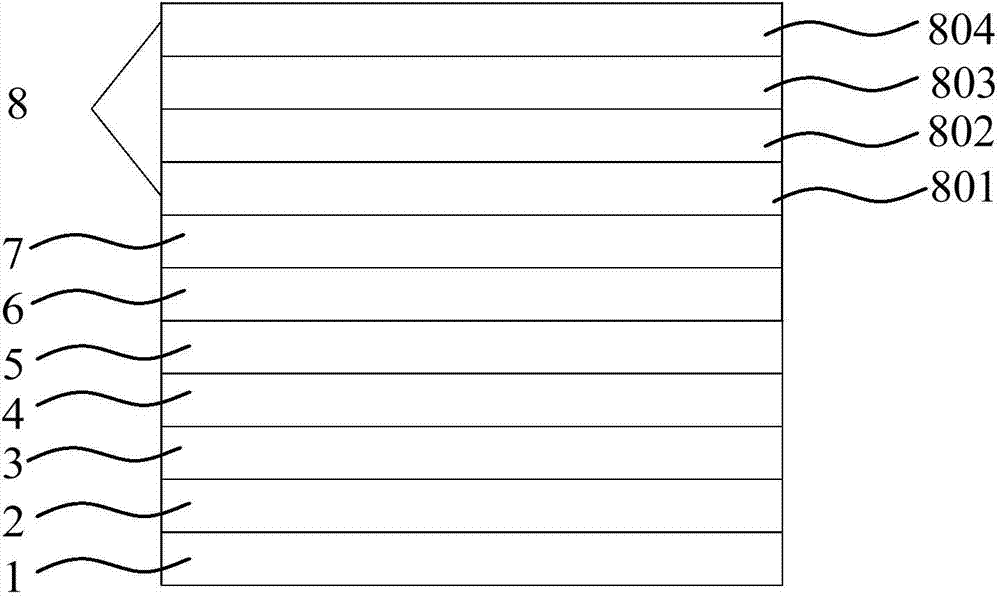

[0061] A method for preparing an organic electroluminescent device, comprising the following steps:

[0062] (1) Pre-treatment of ITO conductive glass substrate 1: put ITO conductive glass substrate 1 into acetone, ethanol, deionized water, and ethanol in sequence, ultrasonically clean them for 5 minutes, then blow dry with nitrogen, and dry them in an oven for later use; The cleaned ITO glass substrate 1 is subjected to surface activation treatment to increase the oxygen content of the conductive surface layer and improve the work function of the conductive layer surface; the thickness of the ITO glass substrate 1 is 100nm;

[0063] Hole injection layer 2: Evaporate MoO on the ITO conductive glass substrate 1 3 Hybrid material obtained by doping NPB, MoO 3The mass of NPB accounts for 30% of the mass of NPB, and the evaporation is carried out by high vacuum coating equipment, and the vacuum degree during evaporation is 3×10 -5 Pa, the evaporation rate is A hole injection l...

Embodiment 2

[0082] A method for preparing an organic electroluminescent device, comprising the following steps:

[0083] (1) Same as embodiment 1;

[0084] (2) Prepare an encapsulation layer on the cathode layer to obtain an organic electroluminescent device. The preparation method of the encapsulation layer is as follows:

[0085] Prepare a protective layer on the cathode layer by vacuum evaporation, the material of the protective layer is NPB, and the vacuum degree is 8×10 -5 Pa, the evaporation rate is The thickness is 300nm;

[0086] The fluoride layer is prepared by magnetron sputtering on the protective layer, and the material of the fluoride layer is HfF 4 , with a thickness of 120nm and a background vacuum of 1×10 -5 Pa;

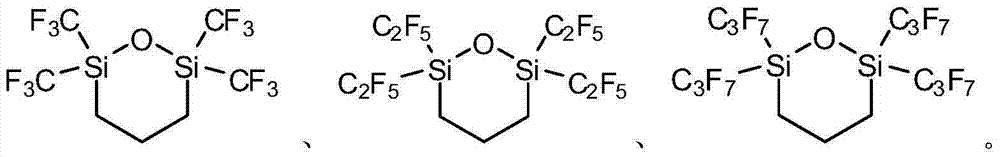

[0087] A PET film is provided, and an organic silicon layer is prepared on the PET film by first spin coating and then exposed to obtain a PET film provided with an organic silicon layer. The material of the organic silicon layer is poly[(3-(bis(pentafluor...

Embodiment 3

[0092] A method for preparing an organic electroluminescent device, comprising the following steps:

[0093] (1) Same as embodiment 1;

[0094] (2) Prepare an encapsulation layer on the cathode layer to obtain an organic electroluminescent device. The preparation method of the encapsulation layer is as follows:

[0095] The method of vacuum evaporation is used to prepare a protective layer on the cathode layer. The material of the protective layer is Alq3, and the vacuum degree is 3×10 -5 Pa, the evaporation rate is The thickness is 250nm;

[0096] The fluoride layer is prepared by magnetron sputtering on the protective layer, and the material of the fluoride layer is ZrF 4 , with a thickness of 150nm and a background vacuum of 2×10 -4 Pa;

[0097] A PET film is provided, and an organic silicon layer is prepared on the PET film by first spin coating and then exposed to obtain a PET film provided with an organic silicon layer. The material of the organic silicon layer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com