Balloon catheter

A balloon catheter and balloon technology are applied in the field of drug-eluting balloon catheters and their preparation, which can solve the problems of drug coating damage, need, life-threatening and the like, achieve good mutual compatibility, reduce drug loss, increase The effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

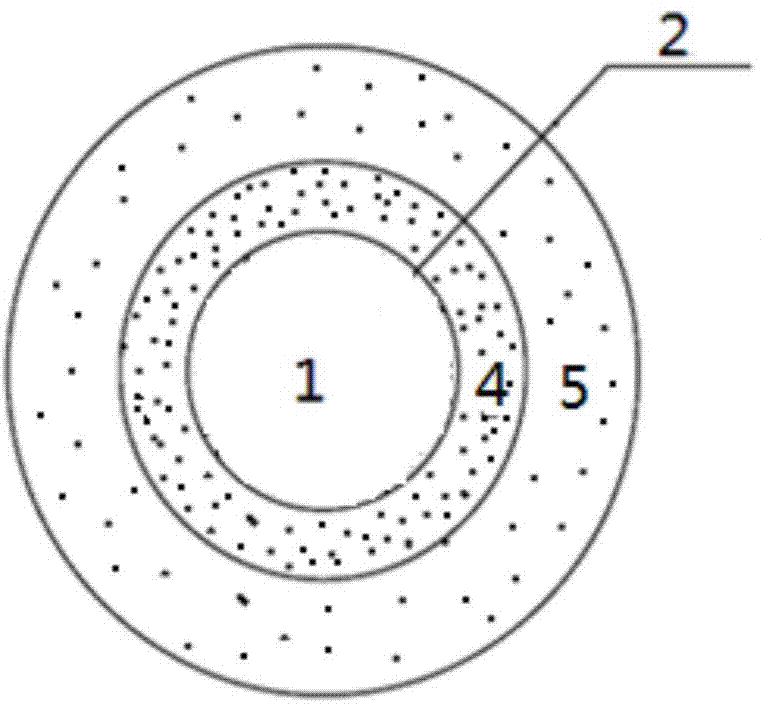

[0048] like figure 1 As shown, take five 3.0mm*20mm (diameter*long) balloon catheters (material: Pebax, block polyetheramide), the balloon is balloon 1 in the schematic diagram, the surface of the balloon is 2, and the balloon catheter is 75 % ethanol to wipe clean and set aside.

[0049] Dissolve 500 mg of paclitaxel and appropriate amount of polyethylene glycol in ethanol to prepare a solution with a drug concentration of 50 mg / ml, and spray this solution on the surface of the balloon to form a drug loading of 5 μg / mm 2 The first drug-loaded coating 4 has a coating thickness of 5 μm.

[0050] Dissolve 200 mg of paclitaxel and appropriate amount of polyethylene glycol in ethanol to prepare a solution with a drug concentration of 20 mg / ml, and spray this solution on the surface of the balloon to form a drug loading of 2 μg / mm 2 The second drug-loaded coating 5 has a coating thickness of 2.5 μm.

[0051] Dried, folded, and packaged, the resulting drug-eluting balloon cathete...

Embodiment 2

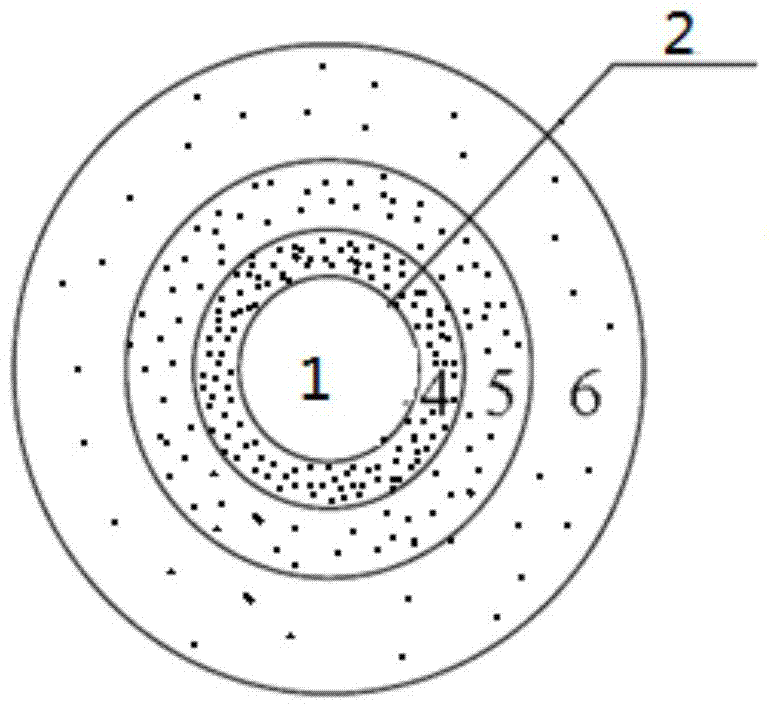

[0053] like figure 2 As shown, take five 3.0mm*20mm (diameter*long) balloon catheters (material: Pebax), the balloon is balloon 1 in the schematic diagram, and the surface of the balloon is 2, wipe it clean with 75% ethanol, spare.

[0054] Dissolve 500 mg of paclitaxel and appropriate amount of polyethylene glycol in ethanol to prepare a solution with a drug concentration of 50 mg / ml, and spray this solution on the surface of the balloon to form a drug loading of 5 μg / mm 2 The first drug-loaded coating 4 has a coating thickness of 5 μm.

[0055] Dissolve 200 mg of paclitaxel and appropriate amount of polyethylene glycol in ethanol to prepare a solution with a drug concentration of 20 mg / ml, and spray this solution on the surface of the balloon to form a drug loading of 2 μg / mm 2 The second drug-loaded coating 5 has a coating thickness of 1 μm.

[0056] Dissolve 100 mg of paclitaxel and appropriate amount of polyethylene glycol in ethanol to prepare a solution with a drug ...

Embodiment 3

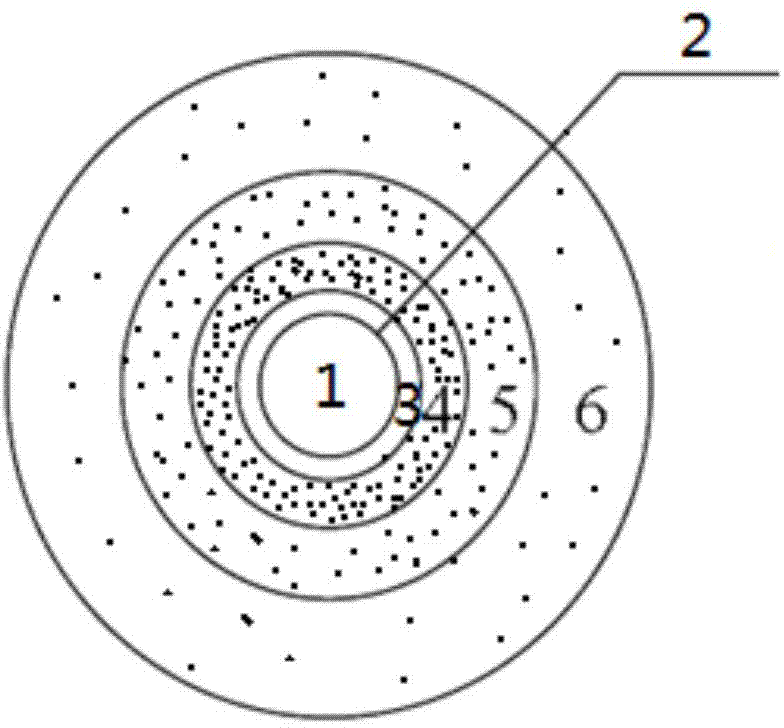

[0059] like figure 2 As shown, take five 3.0mm*20mm (diameter*long) balloon catheters (material: nylon), the balloon is balloon 1 in the schematic diagram, and the surface of the balloon is 2, wipe it clean with 75% ethanol, spare.

[0060] Plasma cleaning technology was used to clean the debris on the surface of the balloon, and the plasma cleaning time was 15 minutes. The plasma cleaning technology uses argon as the inert gas, the power is 10KHz-100KHz, and the pressure in the working chamber is 0.01atm-0.3atm during cleaning.

[0061] Dissolve 500 mg of rapamycin and appropriate amount of polyethylene glycol-polycaprolactone in ethanol to prepare a solution with a drug concentration of 50 mg / ml, and spray this solution on the surface of the balloon to form a drug loading of 5 μg / mm 2 The first drug-loaded coating 4 has a coating thickness of 10 μm.

[0062] Dissolve 200 mg of rapamycin and an appropriate amount of polyethylene glycol-polycaprolactone in ethanol to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com