Application of Surface Restoration Technology to Improve the Impact Strength of Concrete

A technology of impact resistance and surface repair, which is applied in building maintenance, construction, building construction, etc., can solve the problems of complex cutting and manufacturing of fiber composite materials and steel plates, reduced applicability of concrete structures, and high requirements for construction operations. Avoid dead angle processing difficulties, reduce construction and material costs, eliminate the effect of peeling damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

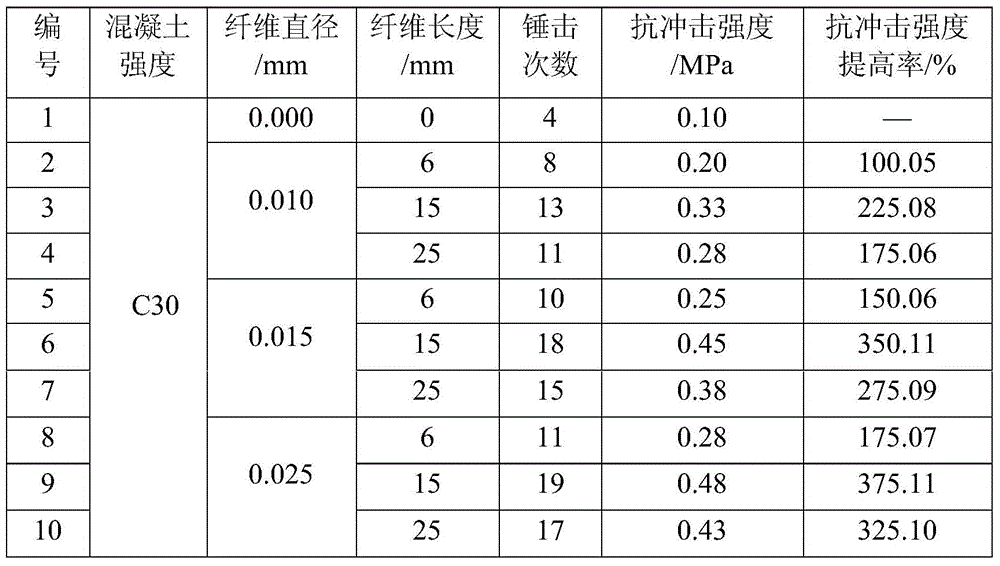

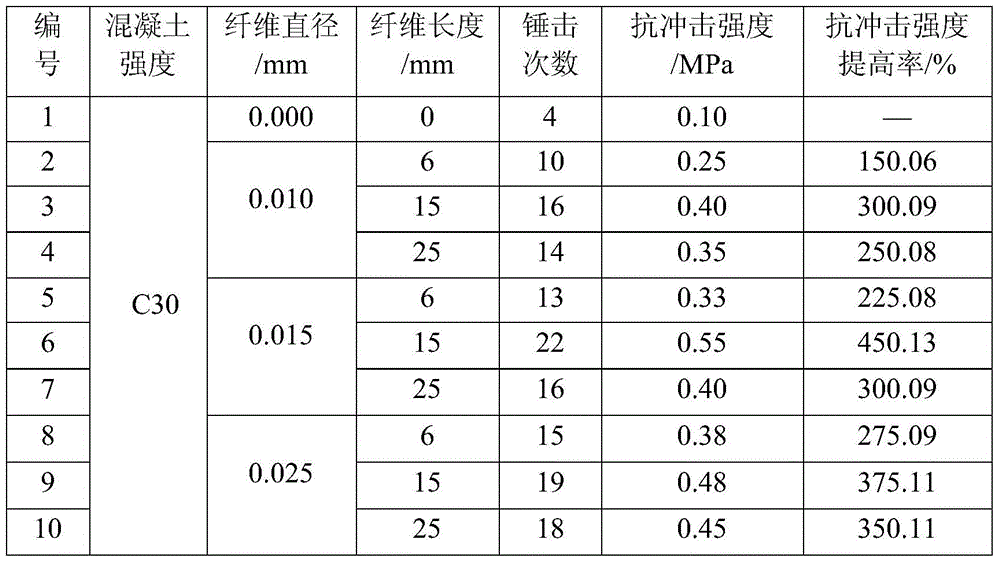

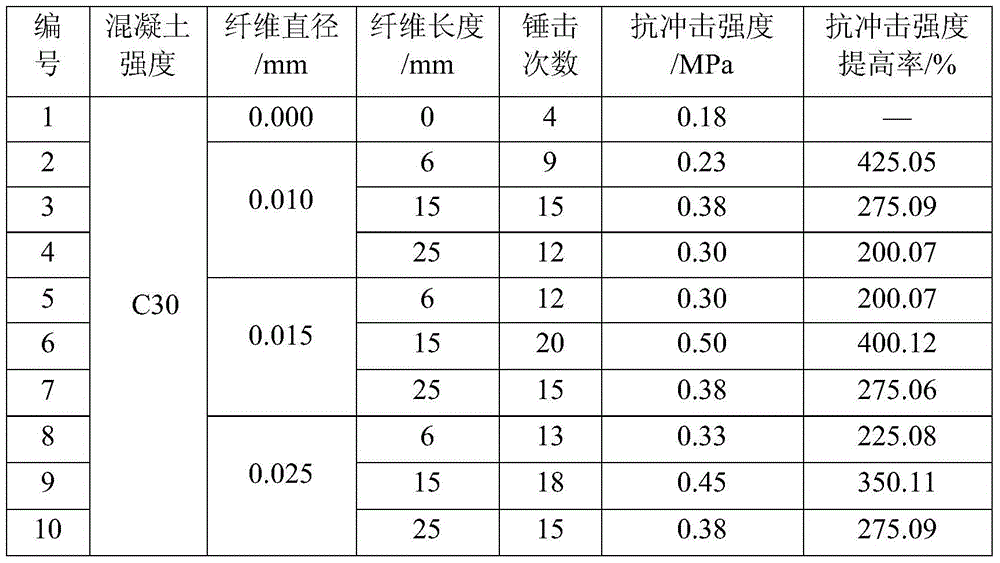

[0029] The composition of raw materials in the implementation example is as follows:

[0030] The concrete is C30 commercial concrete; in order to achieve a good reinforcement effect, so that the adhesive and the fiber can be effectively bonded together, the adhesive is E-51 epoxy resin, phenalkamine curing agent, acetone diluent, nano calcium silicate powder and Polyacrylonitrile staple fiber. Among them, E-51 epoxy resin, viscosity at 23°C is 2500mPa.s; phenalkamine curing agent, model T-5, Henan Tianze Industrial Co., Ltd., brown-red transparent liquid with a density of 0.9-1.1g / cm 3 , the viscosity is 5000mPa.s, the total amine value is 450+20KOHmg / g; the diameter of polyacrylonitrile staple fiber is selected as 0.010mm, 0.015mm and 0.025mm, and the fiber length is selected as 6mm, 15mm and 25mm. Accounting for the volume percentage of the structural adhesive) is 10%, 20% and 30%; the proportion of the structural adhesive is E-51: diluent: curing agent: nano calcium silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com