Recombinant engineering strain of anammox bacterium diamine oxidase

A technology of anaerobic ammonium oxidizing bacteria and recombinant engineering bacteria, applied in the direction of oxidoreductase, genetic engineering, recombinant DNA technology, etc., can solve problems such as harsh growth conditions, polluted water bodies, affecting human activities and health, and achieve increased expression and functional activity, and the effect of shortening the expression time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

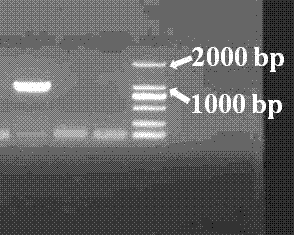

[0026] The hydrazine oxidase HZO gene sequence was amplified, and the primers were as follows:

[0027] Forward primer hzoF1:5 , -TGTGCATGGTCAATTGAAAG-3 , ;

[0028] reverse primer hzoR1:5 , -CAACCTCTTCWGCAGGTGCATG-3 , .

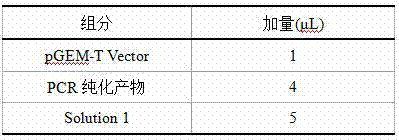

[0029] 5 of upstream and downstream primers , A restriction site was designed at the end for connection with the expression vector pGEM-T. The gene sequence of hydrazine oxidase HZO was amplified by PCR with primers containing restriction sites. The specific system and amplification conditions are as follows:

[0030] PCR reaction system for amplifying HZO:

[0031]

[0032] PCR amplification conditions (or colony PCR amplification conditions) are:

[0033] Pre-denaturation at 94°C for 5 minutes

[0034]

[0035] Construction of pGEM-T-HZO recombinant vector:

[0036] The PCR purified product containing the ammonia oxidase HZO gene sequence was connected to the pGEM-T vector by DNA ligase overnight at 4°C, and the ligated product was introdu...

Embodiment 2

[0040] Preservation of Gene Recombined Engineering Bacteria

[0041] Take a clean 250mL Erlenmeyer flask, add ultrapure water:glycerol=50:50 ultrapure water and glycerin into it, wait until the solution is evenly mixed, and sterilize at 120°C for 20 min. Add 1800 μL and 1200 μL of the sterilized glycerin aqueous solution and recombinant engineered bacteria to a 5mL sterilized centrifuge tube (to ensure that the glycerol content in the final sterile glycerol aqueous solution is 30%), mix the solutions evenly, and store them at -80°C.

Embodiment 3

[0043] Application of Gene Recombination Engineering Bacteria

[0044] Use LB liquid medium to expand (20 times) to cultivate HZO gene recombinant engineered bacteria to OD 600 reached 0.6. Take 20 mL of bacterial liquid, apply it to 100 mL of hydrazine-contaminated solution with an initial concentration of 45 mg / L, and shake at 200 rpm for 28 hours at 37°C. Take 5mL of the reaction solution and pass it through a 0.22μm filter membrane, and use p-dimethylaminophenol spectrophotometry to detect the concentration of residual hydrazine in the solution during the reaction, and the calculated removal rate is 98%. At the same time, take 5mL of the reaction solution and detect it with a UV-4802 spectrophotometer, using OD 600 The value represents the growth of the bacterium, and the growth of the HZO gene recombination engineered bacteria showed a complete S-shaped growth curve after testing.

[0045] Shanghai University

[0046] Recombinant engineering bacteria of anammox bacter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com