A nanoscale aluminum-based metal-organic framework material and its preparation method

An organic framework, nanoscale technology, applied in the fields of magnetism, nanotechnology, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Aluminum isopropoxide was used as the organic aluminum source (0.706g, 3.46mmol) and 1,4-BDC (0.287g, 1.73mmol) (molar ratio Al:1,4-BDC=2:1), and the weighed medicine and 5mL of water was mixed, stirred evenly, and placed in a polytetrafluoroethylene reactor. The experiment adopted a temperature-programmed method of 3°C / min. The reaction temperature was 210°C, and the holding time was 72 hours. After the reaction was completed, the temperature was lowered to room temperature and then taken out. The reaction solution was washed with deionized water and ethanol in sequence, and dried at room temperature to finally obtain a light yellow powder.

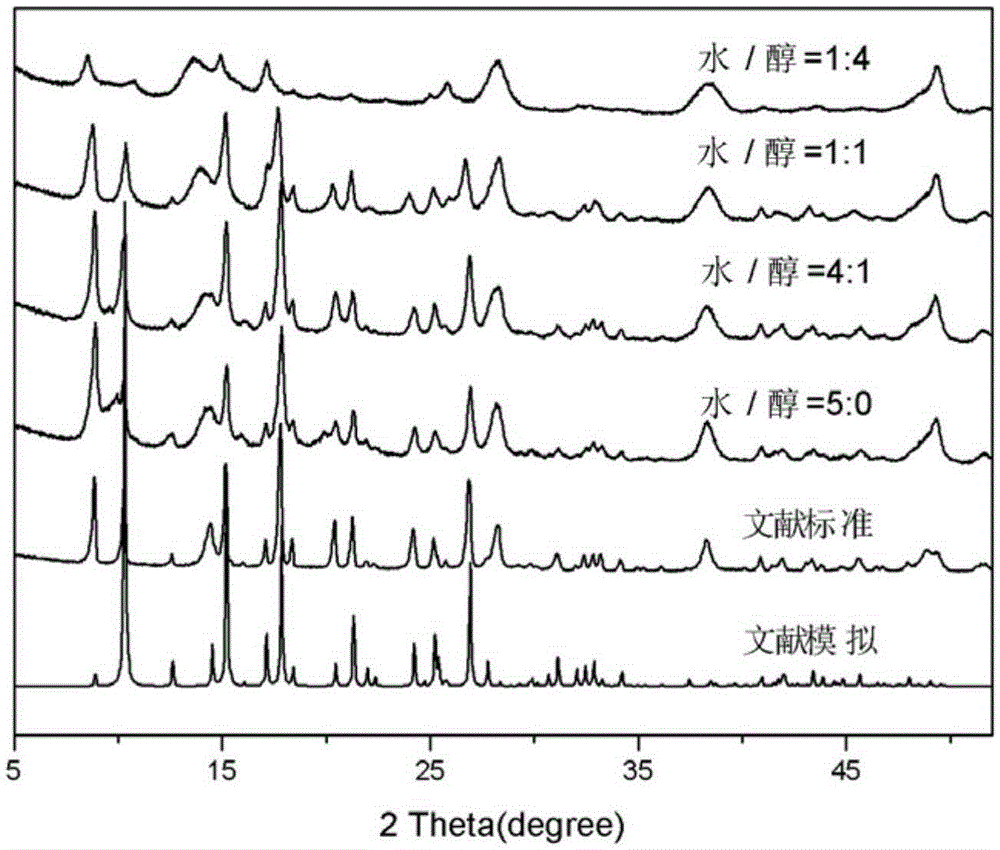

[0023] Take some samples for XRD characterization, such as figure 1 As shown, it can be seen that the synthesized product and the standard XRD spectrum (MichaelMaes, FrederikVermoortele, LucAlaerts, SarahCouck, ChristineE.A.Kirschhock, JoeriF.M.Denayer, and DirkE .DeVos, J.Am.Chem.Soc., 2010, 132(43), 15277–15285; Fajula and Gé...

Embodiment 2

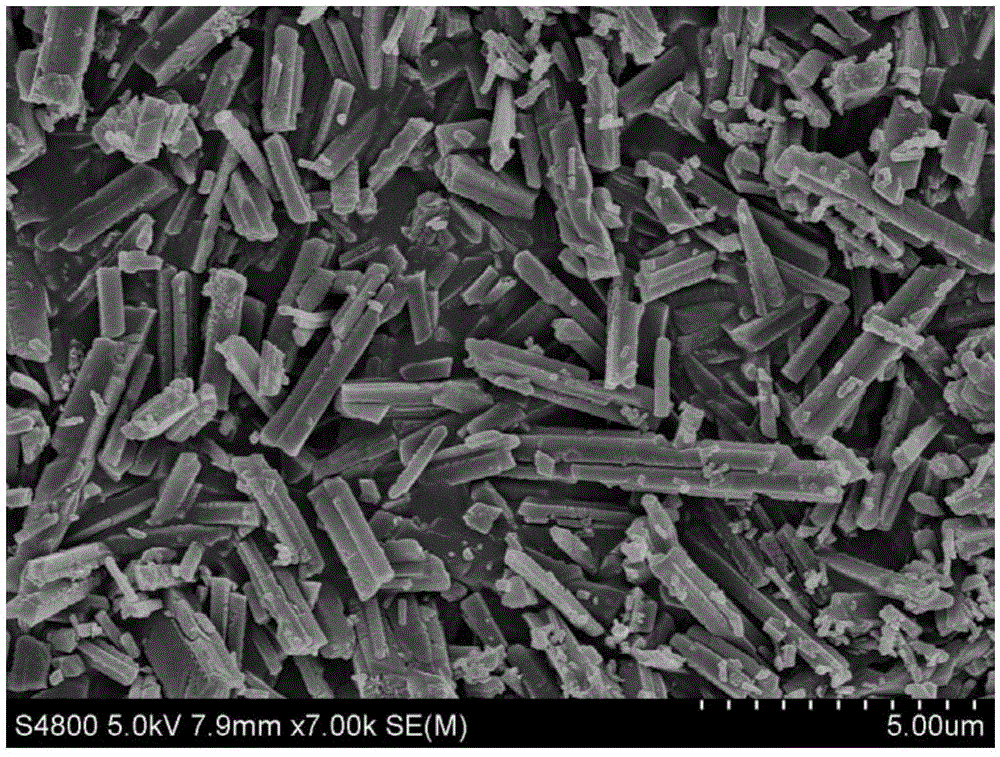

[0026] Aluminum isopropoxide is used as the organic aluminum source (0.706g, 3.46mmol) and 1,4-BDC (0.287g, 1.73mmol), (molar ratio Al: 1,4-BDC = 2: 1), the weighed drug Mix it with 4mL water + 1mL ethanol, stir evenly, and place it in a polytetrafluoroethylene reactor. The experiment adopts the method of temperature programming at 3°C / min, the reaction temperature is 210°C, and the holding time is 72 hours. After the reaction was completed, the temperature was lowered to room temperature and then taken out. The reaction solution was washed with deionized water and ethanol in sequence, and dried at room temperature to finally obtain a light yellow powder. Take some samples for XRD characterization, such as figure 1 As shown, it can be seen that the synthesized product matches the MIL-53 (Al) standard XRD spectrum; from image 3 It can be seen that the products synthesized under this condition are still dominated by rod-like structures, but accompanied by the formation of nano...

Embodiment 3

[0028] Aluminum isopropoxide was used as the organic aluminum source (0.706g, 3.46mmol) and 1,4-BDC (0.287g, 1.73mmol) (molar ratio Al:1,4-BDC=2:1), and the weighed medicine and 2.5mL water + 2.5mL ethanol were mixed, stirred evenly, and placed in a polytetrafluoroethylene reactor. The experiment adopted a 3°C / min temperature programming method, the reaction temperature was 210°C, and the holding time was 72 hours. After the reaction was completed, the temperature was lowered to room temperature and then taken out. The reaction solution was washed with deionized water and ethanol in sequence, and dried at room temperature to finally obtain a light yellow powder.

[0029] Some samples were taken for XRD characterization, from figure 1 It can be seen that the synthesized products are consistent with the MIL-53 (Al) standard XRD spectrum, the crystallinity is good, and the samples are pure. And by comparing the XRD spectra of the two, it can be seen that the (1,0,1) plane is wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com