Preparation method of znse nanocrystal, preparation method of znse nanocrystal and znse buffer layer

A nanocrystal, buffer layer technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of narrow band gap, short-wave absorption and photoelectric conversion response effects, and pollution limit CIGS solar cells Large-scale development and other problems, to achieve the effect of no voids and cracks, avoiding cadmium pollution, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

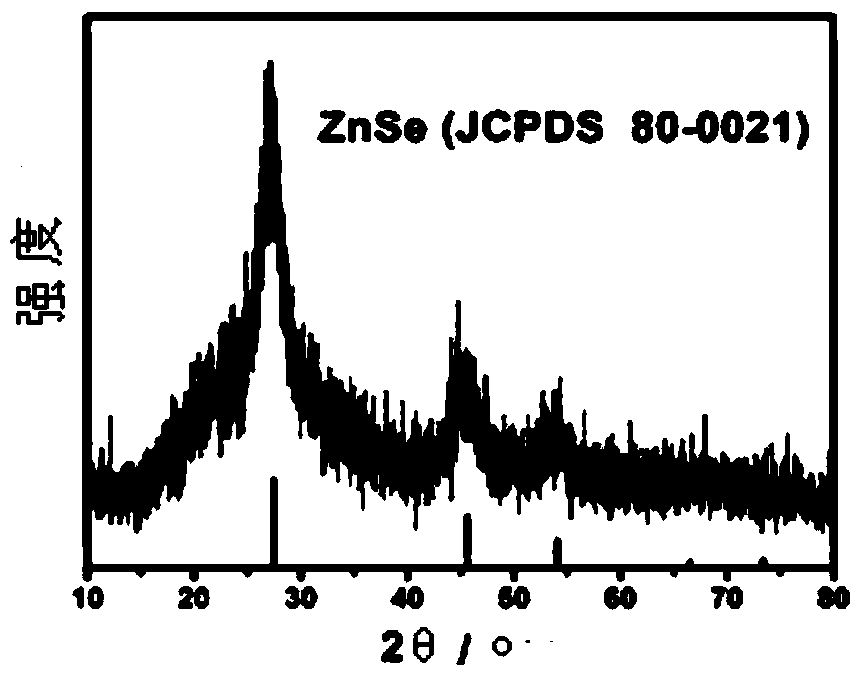

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of ZnSe nano crystal, in specific embodiment, this preparation method comprises the steps:

[0025] S1. Preparation of selenium precursor solution: make oleylamine, selenium simple substance and reducing agent into a reaction solution, heat and react to obtain a selenium precursor solution; in the reaction solution, the concentration of the selenium precursor solution is 0.25-1.5mol / L, the molar ratio of described reductant and described selenium element ≥ 1:1, and described reductant is dimethylamine borane or sodium borohydride;

[0026] S2. Prepare the zinc precursor solution: disperse the zinc source in the reaction solvent to prepare the zinc precursor solution, the molar ratio between the zinc source and the selenium element is 1:1-1:1.5, and the reaction solvent Oleylamine or a mixed solvent of octadecene and stearic fatty acid;

[0027] S3. Preparation of ZnSe nanocrystals: In an anhydrous and oxygen-free sys...

Embodiment 1

[0048] A preparation method for ZnSe nanocrystals, comprising the steps of:

[0049]S1. Preparation of selenium precursor solution: Add 1.5mL of oleylamine, 1.5mmol of selenium powder and 0.75mmol of dimethylamine borane into a 25mL flask, heat to 130°C while stirring, and after 5 minutes, the selenium powder Dissolved, the color of the solution changed from colorless to dark brown, and then turned into a colorless and transparent selenium precursor solution. The temperature of the selenium precursor solution was lowered to 70° C. for later use.

[0050] S2. Preparation of zinc precursor solution: 1.5 mmol of zinc acetylacetonate, 10 mL of octadecene and 3 mmol of hard fatty acid were added into a 50 mL three-necked flask.

[0051] S3. Preparation of ZnSe nanocrystals: place the three-neck flask in step S2 under a standard anhydrous and oxygen-free system (Schlenk system) to remove water and oxygen for 1 hour. Then the temperature was raised to 230°C. At this temperature, th...

Embodiment 2

[0055] A preparation method for a ZnSe buffer layer, comprising the steps of:

[0056] (1) The ZnSe nanocrystals prepared in Example 1 were dispersed in toluene at a solid-to-liquid ratio of 200 mg / mL to prepare a uniform and stable ZnSe nanocrystal ink.

[0057] (2) adopt the method for electrodeposition to deposit the absorption layer of CIGS thin-film solar cell on molybdenum glass, drip the ZnSe nano-crystal ink in step (1) on this absorption layer, scrape ZnSe nano-crystal ink with scraper to form a film . Then heat and dry at 100°C in a vacuum drying oven to form a dense, uniform zinc selenide film with a thickness of 50nm. The prepared zinc selenide buffer layer samples are stored at normal temperature and in a dry environment for future use. craft use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com