Electromagnetic shielding composite rubber material and preparation method thereof

A conductive composite material and composite rubber technology, applied in the direction of rubber layered products, chemical instruments and methods, lamination, etc., can solve the problem of incompatibility of high electrical conductivity and high magnetic permeability, lower mechanical properties of materials, conductive fillers, etc. Easy to oxidize and other problems, achieve the effect of stable shielding effect, good performance and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

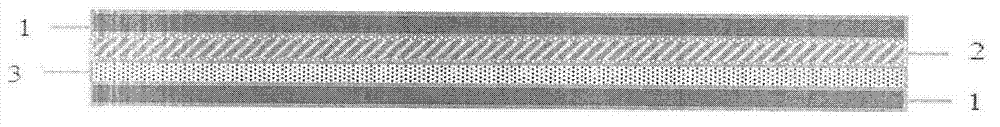

Image

Examples

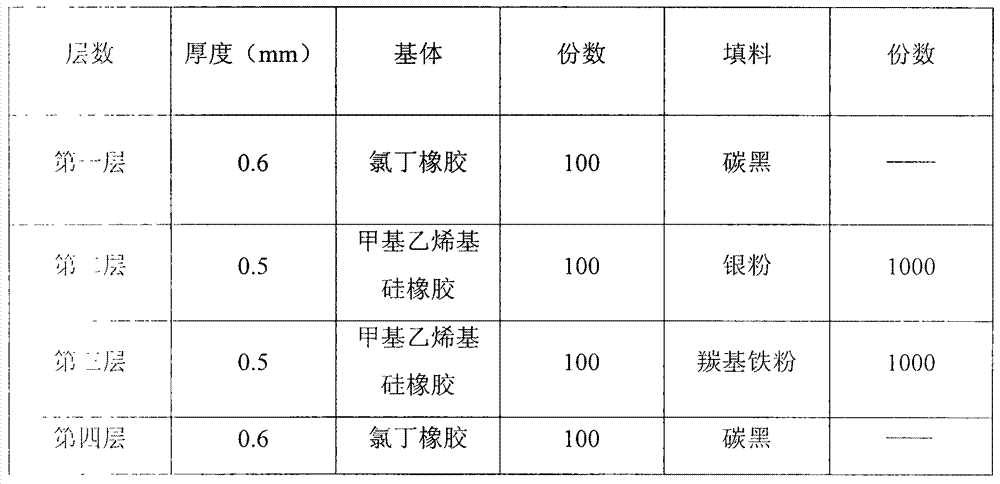

Embodiment 1

[0073]

[0074] The processing steps are as follows:

[0075] a) Mixing:

[0076] a-1) Raw rubber heating: use an open mill to masticate methyl vinyl silicone rubber raw rubber, and heat to soften;

[0077] a-2) Add 300 parts of anti-aging agent to the softened glue prepared in step a-1); and mix evenly;

[0078] a-3) Add 1000 parts of silver powder to the material prepared in step a-2), and mix evenly;

[0079] a-4) add vulcanizing agent bis 2,5 (2,5-dimethyl-2,5 bis (tert-butyl peroxy) hexane) part to the material prepared in step a-3), vulcanize Accelerator NA-22, 0.5 parts, and mix well;

[0080] a-5) Homogenous mixing: kneading and mixing evenly;

[0081] a-6) the lower film;

[0082] b) Production:

[0083] b-1) Heating the mixed rubber: heating the mixed rubber prepared in step a-5) with an open mill to obtain a flowable mixed rubber;

[0084] b-2) calendering: calendering with a calender;

[0085] Repeat step a) and step b) to make the magnetic silicon rubbe...

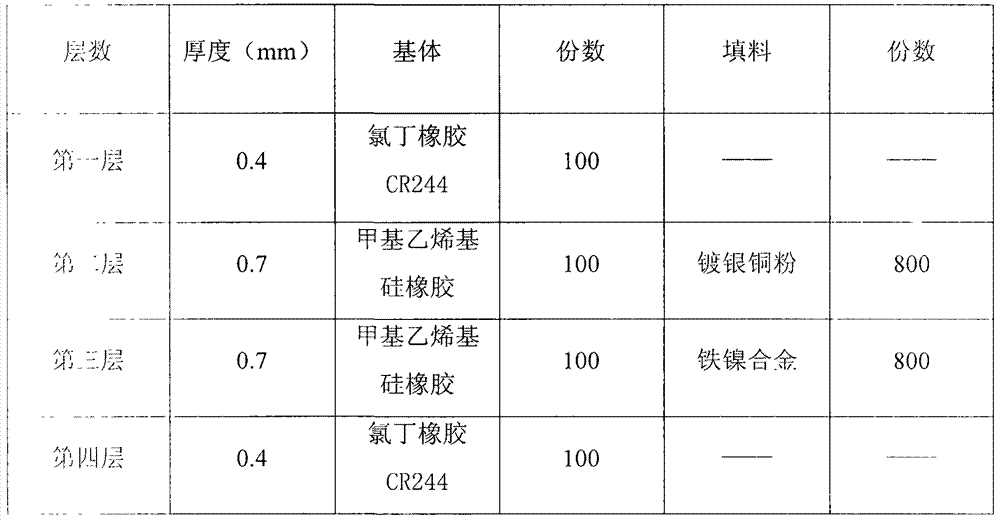

Embodiment 2

[0089]

[0090] The processing steps are as follows:

[0091] a) Mixing:

[0092] a-1) Raw rubber heating: use an open mill to masticate methyl vinyl silicone rubber raw rubber, and heat to soften;

[0093] a-2) Add one part of anti-aging agent 2246 to the softened glue prepared in step a-1); and mix evenly;

[0094] a-3) Add 1000 parts of silver-plated copper powder to the material prepared in step a-2), and mix evenly;

[0095] a-4) Add vulcanizing agent double 2, 4 parts, vulcanization accelerator M, one part to the material prepared in step a-3), and mix uniformly;

[0096] a-5) Homogenous mixing: kneading and mixing evenly;

[0097] a-6) the lower film;

[0098] b) Production:

[0099] b-1) Heating the mixed rubber: heating the mixed rubber prepared in step a-5) with an open mill to obtain a flowable mixed rubber;

[0100] b-2) calendering: calendering with a calender;

[0101] Repeat step a) and step b) to make respectively the magnetically permeable silicon ru...

Embodiment 3

[0105]

[0106] The processing steps are as follows:

[0107] a) Mixing:

[0108] a-1) Raw rubber heating: use an open mill to masticate methyl vinyl silicone rubber raw rubber, and heat to soften;

[0109] a-2) Add one part of anti-aging agent 2246 to the softened glue prepared in step a-1); and mix evenly;

[0110] a-3) Add 1000 parts of silver-plated glass microspheres to the material prepared in step a-2), and mix uniformly;

[0111] a-4) Add 2.5 parts of vulcanizing agent di-secondary dicarboxylate and 3.5 parts of vulcanization accelerator TAIC to the material prepared in step a-3), and mix uniformly;

[0112] a-5) Homogenous mixing: kneading and mixing evenly;

[0113] a-6) the lower film;

[0114] b) Production:

[0115] b-1) Heating the mixed rubber: heating the mixed rubber prepared in step a-5) with an open mill to obtain a flowable mixed rubber;

[0116] b-2) calendering: calendering with a calender;

[0117] Repeat step a) and step b) to make respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com