Diamond rotation body grinding wheel line electrode discharging and turning compound dressing method and device

A technology of diamond grinding wheel and dressing device, which is applied in the direction of abrasive surface adjustment device, metal processing equipment, grinding machine parts, etc. , to achieve the effect of facilitating mechanical motion control, accurate and convenient display and feedback, and improving trimming efficiency and trimming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

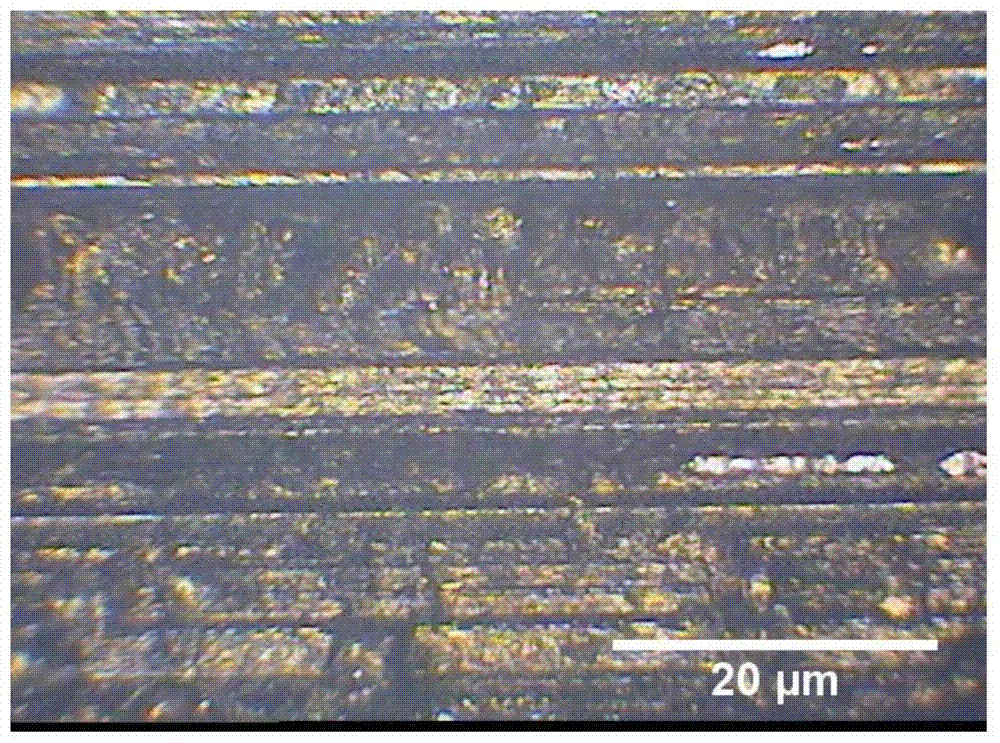

[0054] In this embodiment, the dressing of copper-based sintered diamond grinding wheel is taken as an example. The circular runout of the diamond grinding wheel measured before dressing is 0.18 mm, and the diamond grinding wheel before dressing is used for single grinding. The processed surface is shown in Figure 3 (a) , it can be seen from the figure that the machined surface is rough and uneven.

[0055] Afterwards, utilize the machining conditions shown in the table below, the diamond grinding wheel is trimmed by the trimming method and device of the present invention,

[0056]

[0057] After trimming, the circular runout of the diamond grinding wheel is reduced from 0.18mm to 0.03mm, and the trimmed diamond grinding wheel is used for single grinding. The processed surface is shown in Figure 3(b). It can be seen from the figure that the roughness of the processed surface is Significantly lower, smooth surface.

[0058] The invention discloses a diamond rotary grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com