Complete catalytic oxidation elimination catalyst of dichlorobenzene and preparation method thereof

A completely catalytic oxidation and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of catalyst deactivation, serious pollution and secondary pollution. and other problems, to achieve the effect of low price, simple preparation process and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

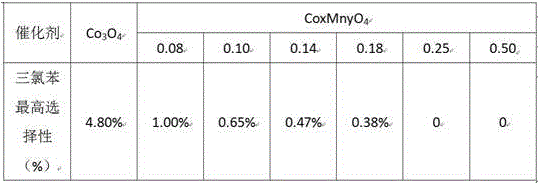

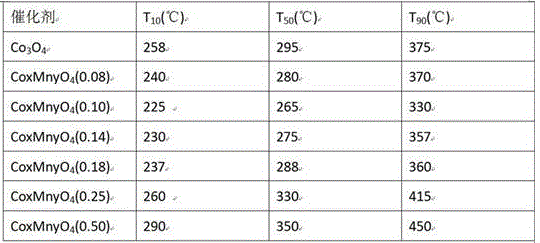

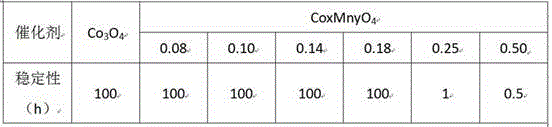

Examples

Embodiment 1

[0016] Add 3.5g of citric acid monohydrate to 250ml of 0.1mol / L cobalt nitrate solution. After the citric acid monohydrate is completely dissolved, transfer the mixed solution to a rotary steamer, and spin steam at 40°C until there is gum formation. Then the temperature was increased to 65°C overnight, and the resulting citrate was dried at 110°C and calcined at 550°C for 4 hours to obtain Co 3 O 4 Catalyst, denoted as Co 3 O 4 .

Embodiment 2

[0018] Add 3.5g of citric acid monohydrate to 250ml of 0.1mol / L mixed solution containing cobalt nitrate and manganese nitrate, where the molar ratio Mn / (Co+Mn)=0.08, transfer the mixed solution after the citric acid monohydrate is completely dissolved On the rotary steamer, rotate at 40°C until there is gum formation, then heat up to 65°C for overnight rotary steaming, dry the obtained citrate at 110°C, and roast at 550°C for 4 hours. Obtain manganese-doped cobalt tetroxide catalyst, denoted as CoxMnyO 4 (0.08).

Embodiment 3

[0020] The cobalt-manganese composite oxide catalyst with Mn / (Co+Mn)=0.10 was prepared according to the method of Example 2, and it was recorded as CoxMnyO 4 (0.10).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com