Preparation method of hydrogenation catalyst and method for synthesizing DMAPA (dimethyl amionopropylamine) by applying catalyst

A technology of hydrogenation catalyst and auxiliary agent, applied in the preparation of organic compounds, metal/metal oxide/metal hydroxide catalyst, preparation of amino compounds, etc., can solve the problems of wasting raw materials, increasing production and operation costs, and reducing The effect of output, saving cost of raw material consumption, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

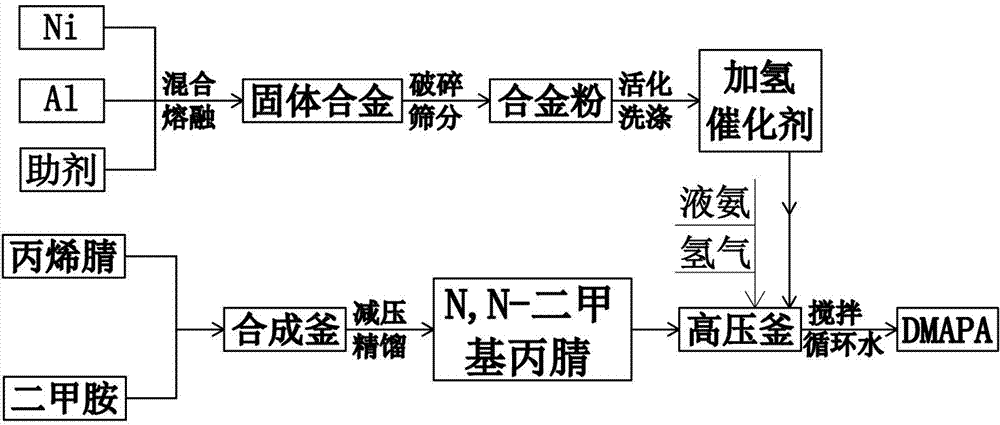

Image

Examples

Embodiment 1

[0031] In parts by mass, weigh the following raw materials, Ni: 50 parts; Al: 46 parts; Co: 1.5 parts; La: 0.2 parts; Cr: 1.0 parts; Fe: 0.8 parts; The raw materials are uniformly mixed and melted at a temperature of 3000°C, cooled under the protection of nitrogen to form a solid alloy, and then crushed and sieved to obtain alloy powder with 80-150 mesh particles; in 30% sodium hydroxide solution Activate to remove most of the Al in the alloy powder, and then wash with deionized water until the pH value is 9-10, and the obtained product is a hydrogenation catalyst.

[0032] Add acrylonitrile to the synthesis kettle, and add dimethylamine dropwise to the synthesis kettle under the conditions of stirring at 50°C and circulating cooling water, wherein the molar ratio of acrylonitrile to the dimethylamine added dropwise is 1 : 1, a small amount of dimethylamine is removed through vacuum distillation to obtain N,N-dimethylpropionitrile;

[0033] Take 1000 g of N,N-dimethylpropioni...

Embodiment 2

[0035] In parts by mass, weigh the following raw materials, Ni: 48 parts; Al: 48 parts; Co: 1.5 parts; La: 0.2 parts; Cr: 1.0 parts; Fe: 0.8 parts; The raw materials are uniformly mixed and melted at a temperature of 2500°C, cooled under the protection of nitrogen to form a solid alloy, and then crushed and sieved to obtain alloy powder with 120-250 mesh particles; in 30% sodium hydroxide solution Activate to remove most of the Al in the alloy powder, and then wash with deionized water until the pH value is 9-10, and the obtained product is a hydrogenation catalyst.

[0036] Add acrylonitrile to the synthesis kettle, and add dimethylamine dropwise to the synthesis kettle under the conditions of stirring at 50°C and circulating cooling water, wherein the molar ratio of acrylonitrile to the dimethylamine added dropwise is 1 : 1, a small amount of dimethylamine is removed through vacuum distillation to obtain N,N-dimethylpropionitrile;

[0037] Take 500 g of prepared N,N-dimethy...

Embodiment 3

[0039] In parts by mass, weigh the following raw materials, Ni: 49 parts; Al: 45 parts; Co: 2 parts; La: 0.5 parts; Cr: 1.5 parts; Fe: 1 part; The raw materials are uniformly mixed and melted at a temperature of 2800°C, cooled under the protection of nitrogen to form a solid alloy, and then crushed and sieved to obtain alloy powder with 120-250 mesh particles; in 30% sodium hydroxide solution Activate to remove most of the Al in the alloy powder, and then wash with deionized water until the pH value is 9-10, and the obtained product is a hydrogenation catalyst.

[0040] Add acrylonitrile to the synthesis kettle, and add dimethylamine dropwise to the synthesis kettle under the conditions of stirring at 50°C and circulating cooling water, wherein the molar ratio of acrylonitrile to the dimethylamine added dropwise is 1 : 1, a small amount of dimethylamine is removed through vacuum distillation to obtain N,N-dimethylpropionitrile;

[0041] Take 1000 g of N,N-dimethylpropionitril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com