Denitrification catalyst for high-temperature flue gas and preparation method thereof

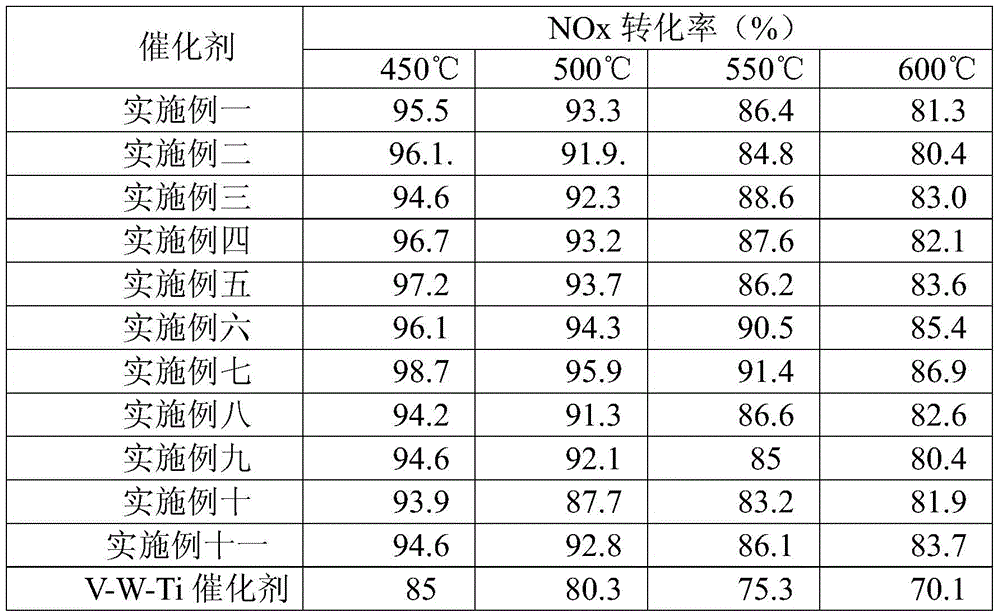

A denitrification catalyst and high-temperature flue gas technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high catalyst denitrification activity and high cost of molecular sieve catalysts problem, to achieve the effect of low cost, simple preparation method and good high temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The composition of the denitration catalyst is W10% / Ce 0.2 Zr 0.8 o 2 Add 1.82g of ammonium paratungstate, 8.68g of cerium nitrate hexahydrate, and 34.34g of zirconium nitrate pentahydrate into 400ml of deionized water, stir until the solids are completely dissolved, then add 12.00g of urea, stir until evenly mixed, heat the solution in a water bath to 100°C and keep it warm Take it out after 4 hours, age it at room temperature for 4 hours, and then dry it in a blast drying oven at 80°C for 10 hours. After drying, put it in a muffle furnace for calcination at 600°C for 5 hours, cool to room temperature, take it out and grind it fully, and pass it through a 40-mesh sieve. The denitrification catalyst is obtained after sieving.

[0020] The specific surface area of the prepared denitration catalyst was measured by the American Beckman SA3100TM specific surface area analyzer to be 102.5m 2 / g.

Embodiment 2

[0022] The composition of the denitration catalyst is W10%-Fe4% / Ce 0.2 Zr 0.8 o 2 , Accurately weigh 1.82g ammonium paratungstate, 2.80g ferric nitrate nonahydrate, 8.68g cerium nitrate hexahydrate, 34.34g zirconium nitrate pentahydrate and add them to 400ml deionized water in turn, stir until the solid is completely dissolved, then add 12.83g urea, stir until Mix evenly, heat the solution in a water bath to 90°C for 6 hours, take it out, age at room temperature for 6 hours, then place it in a blast drying oven at 70°C for 11 hours, and put it into a muffle furnace for calcination at 600°C for 4 hours after drying. Cool to normal temperature, fully grind, and sieve through a 40-mesh sieve to prepare a denitrification catalyst.

[0023] The specific surface area of the prepared denitration catalyst was measured by the American Beckman SA3100TM specific surface area analyzer to be 99.8m 2 / g.

Embodiment 3

[0025] The composition of the denitration catalyst is W20%-Fe4% / Ce 0.2 Zr 0.8 o 2 , add 4.08g ammonium paratungstate, 2.80g ferric nitrate nonahydrate, 8.68g cerium nitrate hexahydrate, 34.34g zirconium nitrate pentahydrate into 400ml deionized water, stir until the solid is completely dissolved, then add 12.83g urea, stir until evenly mixed, and The solution was heated in a water bath at 100°C for 4h, taken out, aged at room temperature for 4h, and then dried in an 80°C blast oven for 12h. After drying, it was placed in a muffle furnace for calcination at 600°C for 5h, cooled to room temperature, and fully Grind and sieve through a 40-mesh sieve to obtain a denitrification catalyst.

[0026] The specific surface area of the prepared denitration catalyst was measured by the American Beckman SA3100TM specific surface area analyzer to be 108.3m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com