Method for displaying original austenite grain boundaries of maraging stainless steel

A technology of austenite grain boundary and display method, which is applied in the preparation of test samples, metal material coating technology, etc., and can solve the problems of difficulty in displaying grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

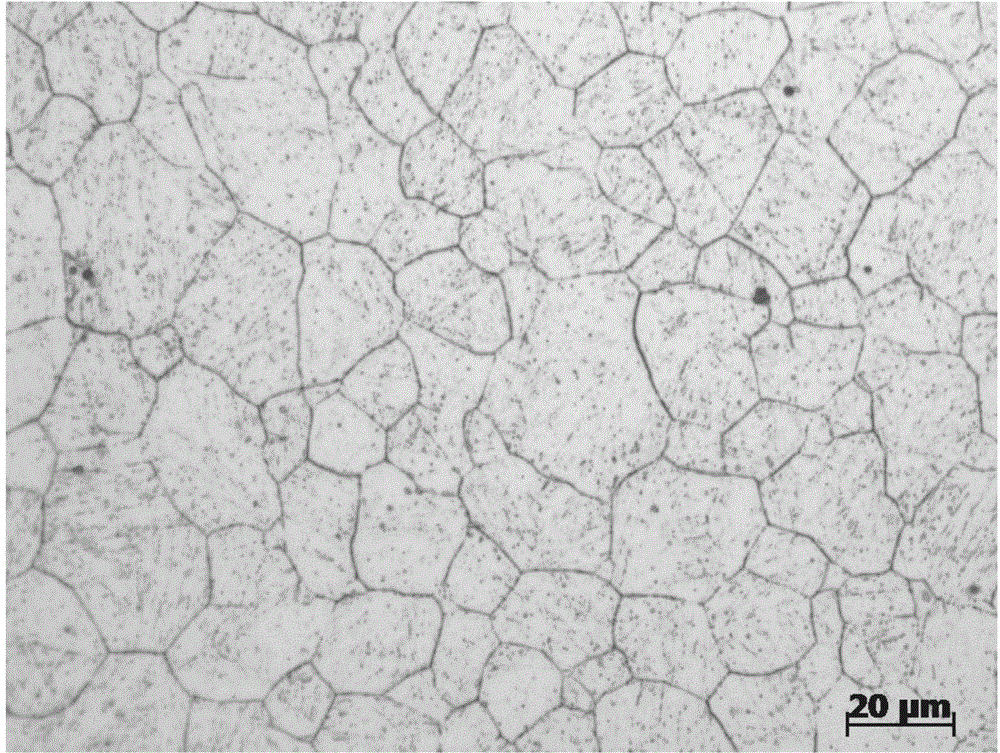

[0026] The photo of aged 17-4PH maraging stainless steel after passivation treatment with 60% nitric acid aqueous solution for 4 minutes and electrolytic etching with 6V voltage for 4 minutes is as follows: figure 1 shown.

[0027] 1. Sample preparation: first cut out the aged sample, and polish one of the planes of the sample on 240#, 600#, 1000#, 2000# metallographic sandpaper from coarse to fine, and then use a particle size of W2. 5 diamond polishing liquid for polishing, polishing to no scratches and then blowing dry. At the same time, in order to prevent the oxide skin on the sample from polluting the electrolyte during the electrolytic etching process, the remaining surfaces only need to be polished with 240# metallographic sandpaper.

[0028] 2. Passivation treatment: Put the polished sample in 60% nitric acid aqueous solution for passivation treatment for 4 minutes;

[0029] 3. Electrolytic etching: The sample that has been passivated in step 2 is subjected to elect...

Embodiment 2

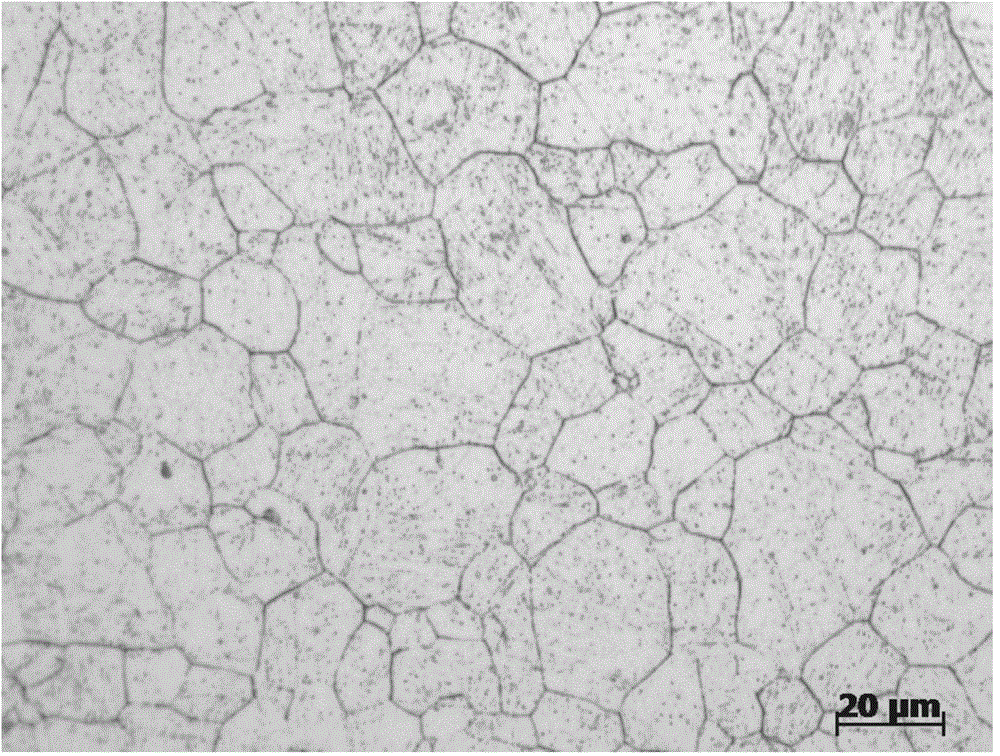

[0031] The photo of the aged 17-4PH maraging stainless steel after passivation treatment with 55% nitric acid aqueous solution for 5 minutes and electrolytic etching with 5V voltage for 5 minutes is as follows: figure 2 shown.

[0032] 1. Sample preparation: same as Example 1.

[0033] 2. Passivation treatment: the passivation solution is 55% nitric acid aqueous solution, and the time is 5 minutes

[0034] 3. Electrolytic etching: the electrolytic etching solution is 55% nitric acid aqueous solution, the voltage is 5V, and the time is 5min. Under the microscope, a clear and complete prior austenite grain boundary without organizational interference can be observed, and the larger black structure is ferrite.

Embodiment 3

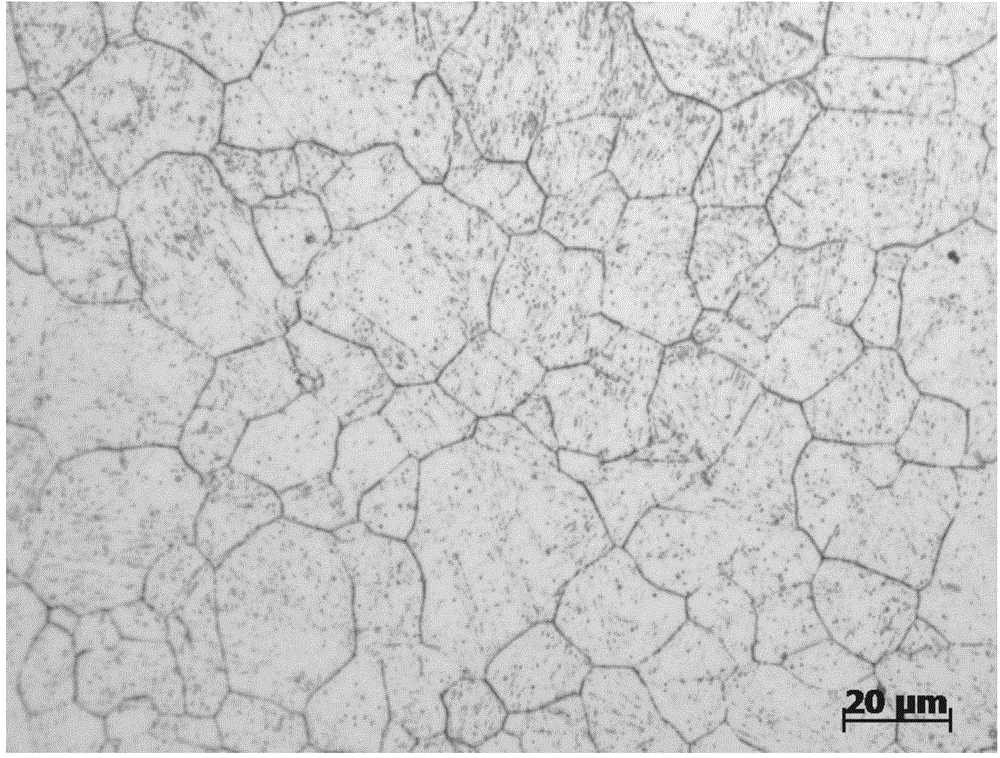

[0036] The photo of the aged 17-4PH maraging stainless steel after passivation treatment with 65% nitric acid aqueous solution for 3 minutes and electrolytic etching with 8V voltage for 3 minutes is as follows: image 3 shown.

[0037] 1. Sample preparation: same as Example 1.

[0038] 2. Passivation treatment: the passivation solution is 65% nitric acid aqueous solution, and the time is 3 minutes

[0039] 3. Electrolytic etching: The electrolytic etching solution is 65% nitric acid aqueous solution, the voltage is 8V, and the time is 3 minutes. Under the microscope, a clear and complete prior austenite grain boundary without organizational interference can be observed, and the larger black structure is ferrite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com