High yield L-leucine engineering bacterium and application thereof

A technology of Leucine and Corynebacterium glutamicum, applied in application, genetic engineering, bacteria, etc., can solve the problems of increased miscellaneous acids, long cycle, heavy workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

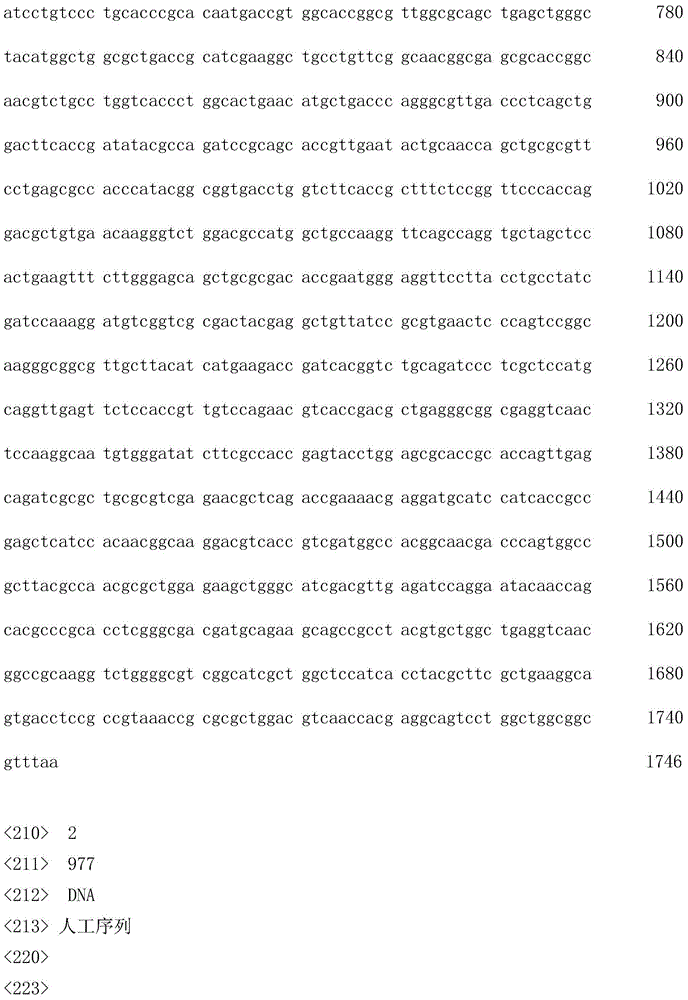

Image

Examples

Embodiment 1

[0031] Embodiment 1, the construction of engineering bacteria

[0032] 1. Exogenous high-level expression of leuA * Construction of recombinant vector

[0033] 1. Cloning and site-directed mutation of leuA gene

[0034] 1), using the genomic DNA of Corynebacterium glutamicum 13032 as a template, carrying out PCR amplification with primers composed of F1 and R1, to obtain a PCR amplification product (leuA gene fragment).

[0035] F1: 5'- GAATTC ATGCCAGTTAACCGCTACATGCCT-3';

[0036] R1: 5'- GTC GAC TTAAACGCCGCCAGCCAGGAC-3'.

[0037] Among them, F1 has an EcoR I restriction site, and R1 has a Sal I restriction site (the underlined partial sequence of the above primer).

[0038] PCR amplification conditions: pre-denaturation at 95°C for 5 minutes; denaturation at 94°C for 40 seconds, annealing at 59°C for 1 minute, extension at 72°C for 2 minutes, 30 cycles; reaction at 72°C for 10 minutes, and incubation at 4°C.

[0039] 2) Recovering the PCR amplified product of step 1)...

Embodiment 2

[0119] Embodiment 2, Corynebacterium glutamicum MD0032 produces L-leucine

[0120] 1. Preparation of culture medium

[0121] Seed medium (pH=6.5-7.0): Take 100g glucose, 5g corn steep liquor, 10g brown sugar, 50g molasses, 100ml soybean meal hydrolyzate (purchased from Shandong Yangcheng Biotechnology Co., Ltd., catalog number DP001), 3g yeast extract , 25g (NH 4 ) 2 SO 4 , 0.2g MgSO 4 ·7H 2 O, 0.05g FeSO 4 ·7H 2 O, 0.3g KH 2 PO 4 ·3H 2 O. Dissolve 0.025g of kanamycin monosulfate and 10g of calcium carbonate in deionized water and adjust the volume to 1L; sterilize at 125°C for 25min.

[0122] Fermentation medium (pH=6.5-7.5): take 120g glucose, 150ml soybean meal hydrolyzate, 27g (NH 4 ) 2 SO 4 , 5.5g KH 2 PO 4 ·3H 2 O, 2.5g K 2 HPO 4 ·3H 2 O, 0.2g MgSO 4 ·7H 2 O, 0.05g FeSO 4 ·7H 2 O, 0.02gMnSO 4 ·H 2 O, 200 μg vitamin H, 200 μg vitamin B1, 100 μg vitamin B2, 100 μg vitamin B6, 0.025 g kanamycin monosulfate, 30 g CaCO 3 Dissolve in deionized water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com