Method for preparing citric acid by fermenting cassava raw material residue-removed clear solution with aspergillus niger

A technology of Aspergillus niger fermentation and citric acid, applied in the field of fermentation, can solve the problems of acid production and unsatisfactory sugar-acid conversion rate, and achieve the effect of promoting the increase of acid production rate and improving the fermentation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

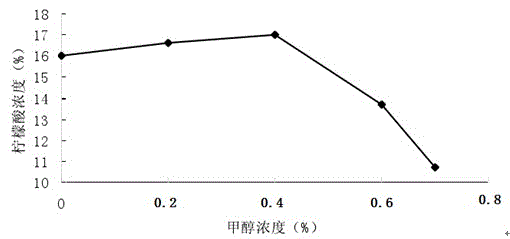

Image

Examples

Embodiment 1

[0017] This implementation case illustrates the influence of different nitrogen sources on the use of Aspergillus niger for citric acid fermentation. The type of nitrogen also has a certain impact, and organic nitrogen is generally preferred. The cassava flour liquefied filtrate was added with corn steep liquor, bran, and rice bran as nitrogen sources, and divided into 250 mL Erlenmeyer flasks. The rotation speed is 300 rpm, the temperature is 39±1°C, and the shaker is cultivated for 96 hours, and the sugar content, acidity and cell concentration are measured. The result is as figure 1 express.

[0018] It can be seen from Table 1 that the yield of citric acid is the highest when corn steep liquor is used as the nitrogen source, the residual sugar content is the lowest when corn steep liquor is the nitrogen source, and the dry weight of bacteria is the most when using rice bran as the nitrogen source. Therefore, from the perspective of citric acid yield, corn steep liquor is...

Embodiment 2

[0022] This implementation case illustrates the influence of different corn steep liquor concentrations on citric acid fermentation using Aspergillus niger. The cassava flour liquefaction filtrate (total sugar is 17.51%) was added with different amounts of corn steep liquor as nitrogen source, and packed into 250 mL triangular In the bottle, the final liquid volume is 50 mL, inoculated with spores, placed on a rotary shaker, the shaker speed is 300 rpm, the temperature is 39±1°C, and the shaker is cultivated for 96 hours, and the sugar content, acidity and bacterial concentration are measured. The optimum addition amount of corn steep liquor was determined by shaking flask test.

[0023] It can be seen from Table 2 that when the concentration of corn steep liquor is 3.5%, the acid production rate and conversion rate of Aspergillus niger citric acid fermentation are the highest, so it is proposed to use the initial fermentation medium with 3.5% corn steep liquor in fed-batch fer...

Embodiment 3

[0027] This implementation case illustrates the influence of different initial sugar concentrations on citric acid fermentation using Aspergillus niger. Cassava flour liquefaction filtrates with different total sugars were prepared, 3.5% corn steep liquor was added as a nitrogen source, and then packed into 250 mL triangular flasks. The liquid volume is 50 mL, inoculated with spores, placed on a rotary shaker, the shaker speed is 300 rpm, and the temperature is 39±1°C for cultivation.

[0028] It can be seen from Table 3 that Aspergillus niger has a certain high sugar tolerance. When the initial sugar concentration is 20.5%, the fermentation can proceed normally, but the conversion rate and production intensity of the fermentation process have decreased. When the initial sugar concentration is 16.5%, the conversion rate can reach 98.63%. Taking various factors into consideration, the initial sugar concentration was selected to be 16.5% for batch fermentation. At this time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com