Device and method for pre-treating raw oil for production of biodiesel

A pretreatment device and biodiesel technology, which is applied in the fuel, petroleum industry, and fat production, etc., can solve the problems of poor quality of finished diesel oil, complex oil composition, and low qualified rate of finished products, and achieve less energy consumption, waste reduction, and treatment Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

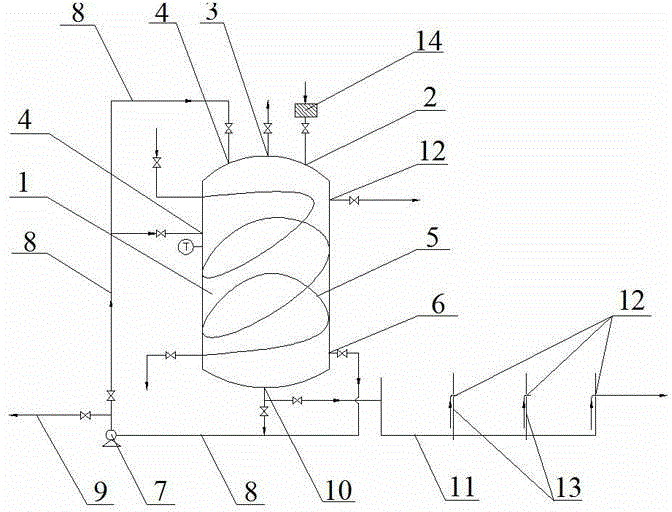

[0021] A raw material oil pretreatment device for biodiesel production, which is provided with a treatment tank 1, and the top of the treatment tank 1 is provided with an oil inlet 2, a vent port 3 and a material return port 4, and the inner circle of the treatment tank 1 is provided with a useful In the heating coil 5 that is fed into the steam, the oil inlet 2 is connected with an oil inlet pipe, and the oil inlet pipe is provided with a filter 14 for filtering impurities of the raw material oil, and the side wall of the treatment tank 1 is also Another material return port 4 is provided, and an oil outlet 6 is arranged below the side wall, and a circulation pump 7 is connected to the oil outlet 6, and the circulation pump 7 connects the oil outlet 6 through a delivery pipeline 8. The discharged material is conveyed into the treatment tank 1 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com