Preparation method of low-temperature high-efficiency denitrification catalyst MnO2

A denitrification catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as poor denitrification effect, and achieve high and stable removal rate Good performance and high selective catalytic reduction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

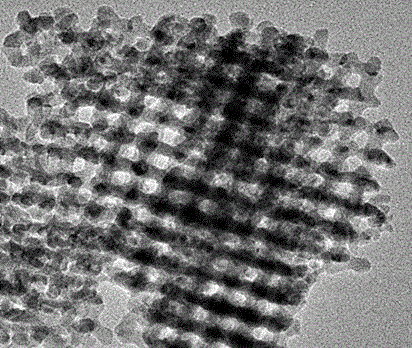

[0022] A low-temperature and high-efficiency denitration catalyst MnO 2 The preparation method, the steps are as follows:

[0023] 1) Dissolve 6g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) in a mixture of 217g of deionized water and 11.8g of 35wt% hydrochloric acid, add 6g of butanol, Stir at 35oC for 1 hour, then add 12.9g tetraethyl orthosilicate (TEOS), and stir at 35oC for 24 hours to obtain a mixed solution;

[0024] 2) Pour the above mixed solution into a closed polypropylene reactor, react at 100oC for 24 hours, collect the obtained solid by centrifugation and dry it at 100oC;

[0025] 3) The above-mentioned dried solid was washed with ethanol-35wt% hydrochloric acid mixture with a volume ratio of 1:1, and then calcined at 550oC to obtain the KIT-6 template;

[0026] 4) Dissolve 3g of manganese nitrate in 25mL of ethanol to obtain a manganese nitrate-ethanol mixture, add 1g of the above KIT-6 template to the manganese nitrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com