Alloy electrode capable of improving efficiency and stability of solar cell

A technology for solar cells and alloy electrodes, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of reducing battery efficiency and stability, reducing battery parallel resistance, etc., to improve stability, improve energy level matching, and improve battery The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

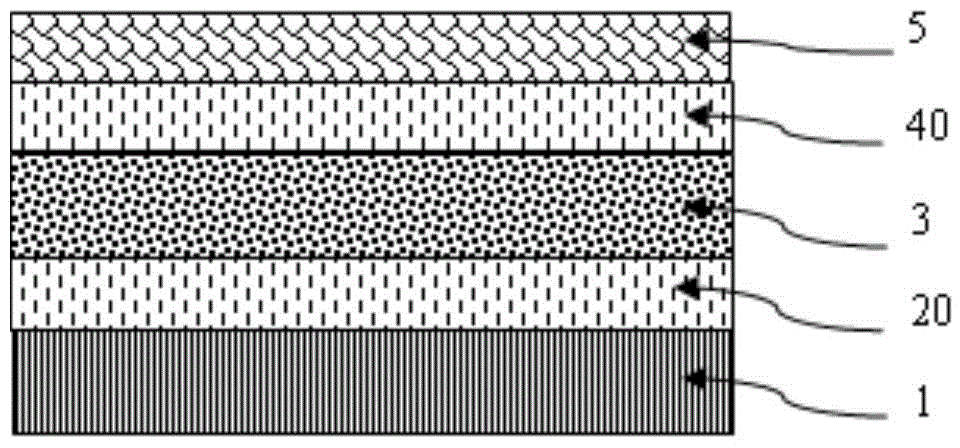

[0036] Such as figure 1 As shown, the perovskite battery structure in this embodiment includes a transparent conductive film 1, an electron transport layer 20, a perovskite light absorbing layer 3, a hole transport layer 40 and an alloy electrode 5 (anode) from bottom to top. A single specific material is given in this embodiment, which does not limit the choice of other materials, but is just an example to illustrate the present invention. The FTO conductive film 1 is ultrasonically cleaned with detergent, deionized water, isopropanol and acetone, dried, and then spin-coated with a 30nm ZnO electron transport layer 20. After annealing, then spin-coated with CH 3 NH 3 PB 3 After the perovskite photoactive layer 3 is annealed at 100°C, a Spiro-OMeTAD hole transport layer 4 is spin-coated, and then a 100nm silver-aluminum alloy electrode 5 is coated by vacuum thermal evaporation. The efficiency of perovskite cells using this structure can reach more than 12%.

Embodiment 2

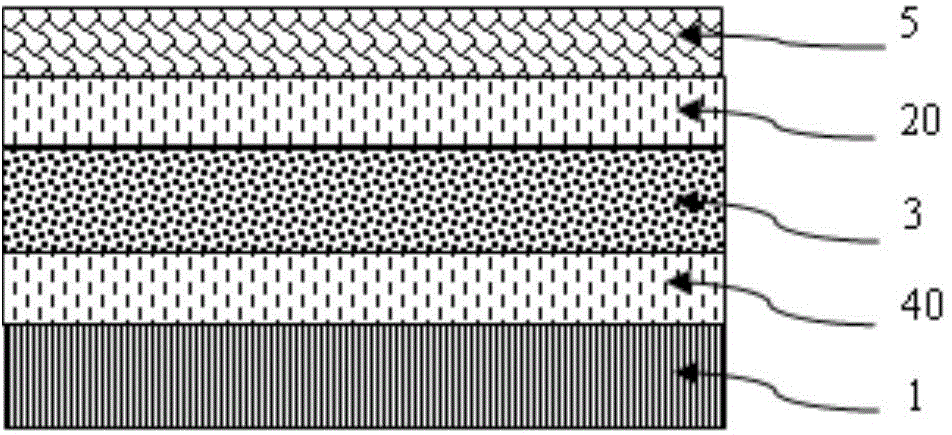

[0038] Such as figure 2 As shown, the perovskite battery structure in this embodiment includes a transparent conductive film 1, a hole transport layer 40, a perovskite light absorbing layer 3, an electron transport layer 20 and an alloy electrode 5 (cathode) from bottom to top. A single specific material is given in this embodiment, which does not limit the choice of other materials, but is just an example to illustrate the present invention. ITO conductive film 1 is ultrasonically cleaned with detergent, deionized water, isopropanol and acetone, dried, and then spin-coated with a 30nm PEDOT:PSS hole transport layer (also called a hole buffer layer) at 40°C and annealed at 140°C followed by spin coating on CH 3 NH 3 PB 3 After the perovskite photoactive layer 3 is annealed at 100°C, a PC60BM electron transport layer 20 is spin-coated, and then a 100nm silver-aluminum alloy electrode 5 is coated by vacuum thermal evaporation. The efficiency of perovskite cells using this s...

Embodiment 3

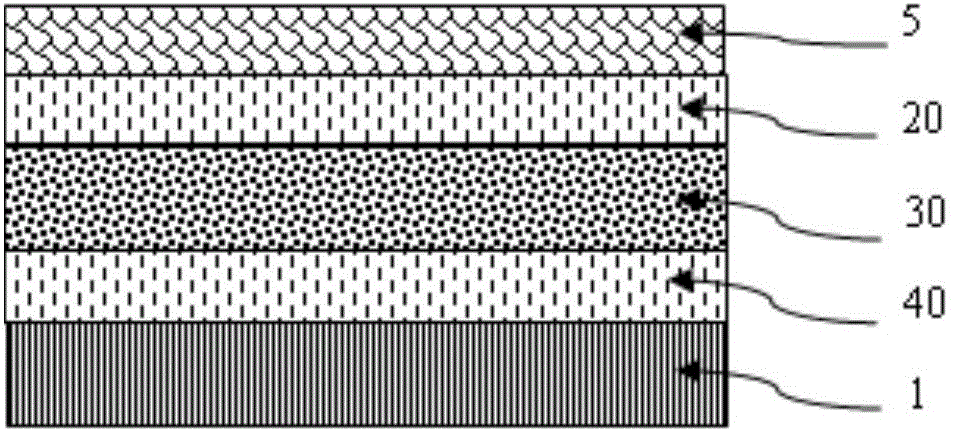

[0040] Such as image 3 As shown, the organic solar cell structure in this embodiment includes a transparent conductive film 1, a hole transport layer 40, an organic light absorption layer 30, an electron transport layer 20 and an alloy electrode 5 (cathode) from bottom to top. A single specific material is given in this embodiment, which does not limit the choice of other materials, but is just an example to illustrate the present invention. ITO conductive film 1 is ultrasonically cleaned with detergent, water, isopropanol and acetone, dried, and then spin-coated with a 40nm PEDOT:PSS hole transport layer (also known as a hole buffer layer) at 40°C and annealed at 140°C. Then spin-coat the photoactive layer 30 mixed with PCE10:PC70BM (ratio 1:1.5), then spin-coat the 30nm ZnO electron transport layer 20, and then coat the 100nm silver-aluminum alloy electrode 5 by vacuum thermal evaporation. The efficiency of the organic solar cell adopting this structure can reach more than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com