Method for manufacturing back contact crystalline silicon solar battery piece

A technology for solar cells and a manufacturing method, which is applied in the field of solar cells, can solve the problems of reducing the parallel resistance of cells, increasing the production cost of cells, and reducing the performance of cells, so as to reduce equipment costs, improve parallel resistance and conversion efficiency, The effect of reducing the risk of electric leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

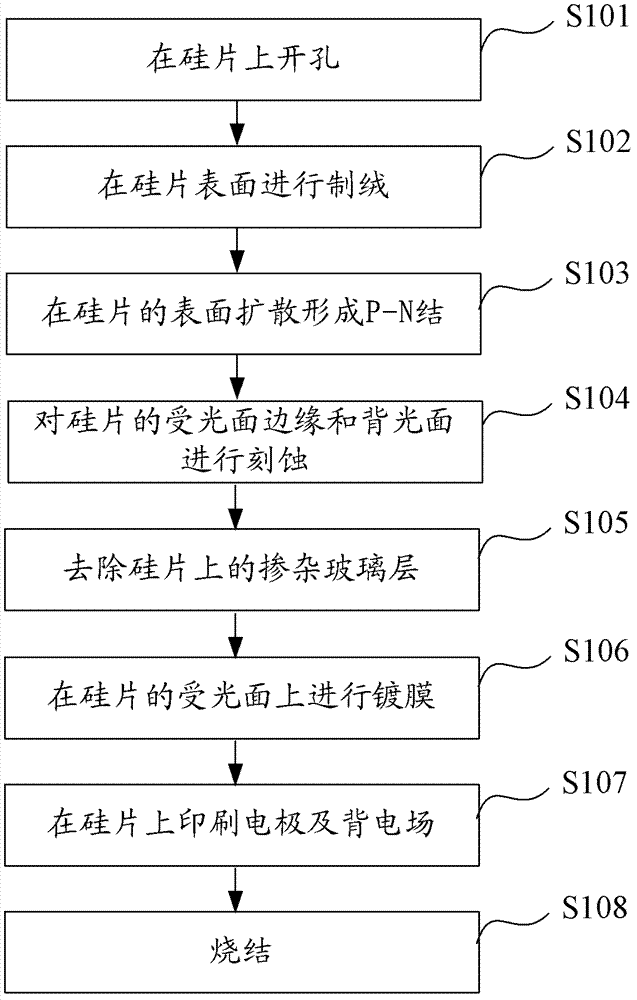

[0059] Please refer to figure 1 , figure 1 The flow chart of the method for manufacturing the back contact crystalline silicon solar cell provided in the first embodiment, as shown in figure 1 As shown, the method includes the following steps:

[0060] Step S101: opening holes on the silicon wafer;

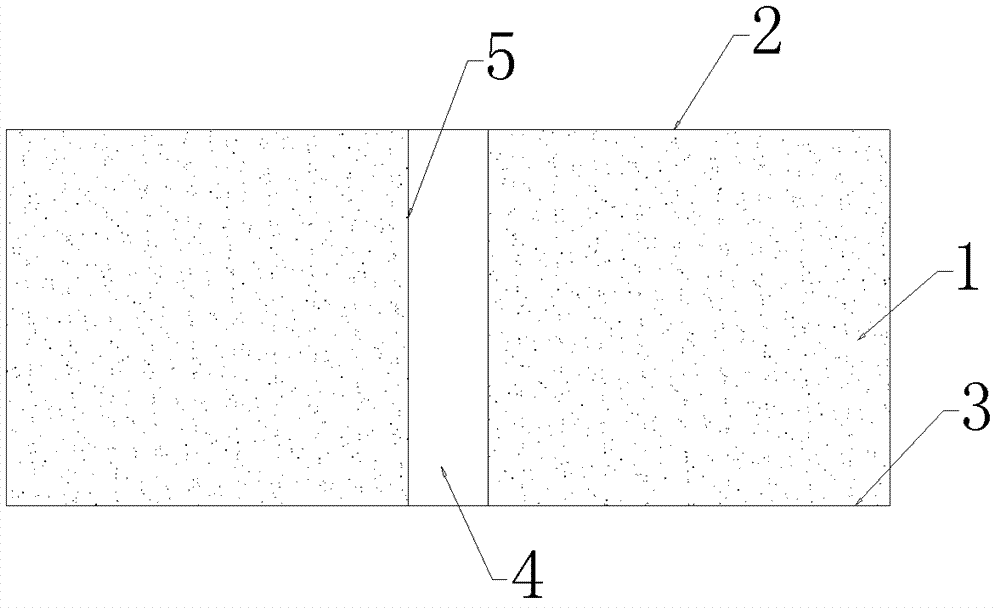

[0061] A laser is used to open at least one through hole on the silicon wafer, which can be used to set electrodes in the through hole to lead the current from the light-receiving surface of the battery to the backlight surface of the battery, so that the positive and negative electrodes of the battery can be located on the back of the battery. The back of the sheet reduces the shading rate of the front grid. In the embodiment of the present invention, the wavelength of the laser used for opening holes may be 1064 nm, 1030 nm, 532 nm or 355 nm. The schematic diagram of the structure of the silicon wafer after opening is as follows: figure 2 As shown, 1 in the figure is a sil...

Embodiment 2

[0081] Please refer to Figure 8 , Figure 8 A flow chart of a method for manufacturing a back-contact crystalline silicon solar cell provided in Example 2, as shown in Figure 8 As shown, the method includes the following steps:

[0082] In this embodiment of the present invention, steps 201 to 203 are the same as steps 101 to 103 in Embodiment 1, and will not be repeated here.

[0083] Step S204: Etching the side surface, backlight surface and all through holes of the silicon wafer;

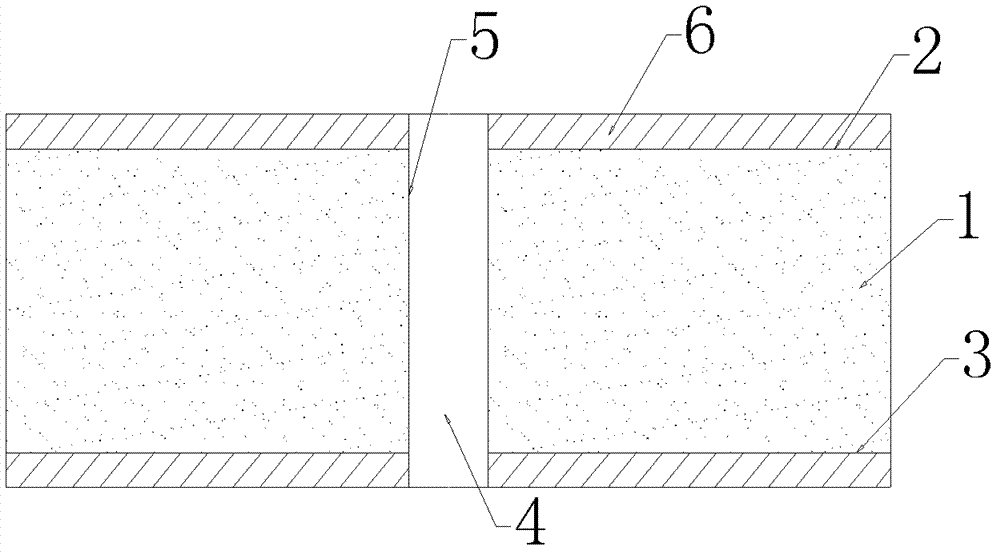

[0084] Figure 9 It is a schematic diagram of the structure of the silicon wafer after etching, such as Figure 9 As shown, after etching, there is no emitter junction on the inner wall 5 and the side of the through hole. In the embodiment of the present invention, during etching, the entire surface, the entire backlight surface, and all the through holes of the silicon wafer 1 can be completely contacted with the chemical solution, and the contact method can be completely soaked with HF (...

Embodiment 3

[0088] Please refer to Figure 11 , Figure 11 A flow chart of a method for manufacturing a back-contact crystalline silicon solar cell provided in Example 2, as shown in Figure 11 As shown, the method includes the following steps:

[0089] In this embodiment of the present invention, steps 301 to 303 are the same as steps 201 to 203 in Embodiment 2, and will not be repeated here.

[0090] Step S304: Etching the side surface, the entire backlight surface and some through holes of the silicon wafer;

[0091] Figure 12 It is a schematic diagram of the structure of the silicon wafer after etching, such as Figure 12 As shown, when the through hole is etched, a section of the through hole along the axis of the through hole is selectively etched, so that after etching, there is a local emitter junction on the inner wall 5 of the through hole. In addition, when etching the side surfaces of the silicon wafer, the entire surface of all the sides of the silicon wafer may be etch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com