Implantable concrete three-dimensional space stress monitoring sensor

A three-dimensional space and stress monitoring technology, which is applied in the measurement of the property force of piezoelectric devices, etc., can solve the problems of easy cracking and damage of cement-based sensors, difficult to ensure the positioning position of piezoelectric sheets, and no concrete triaxial stress. Achieve the effect of low cost, small size and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

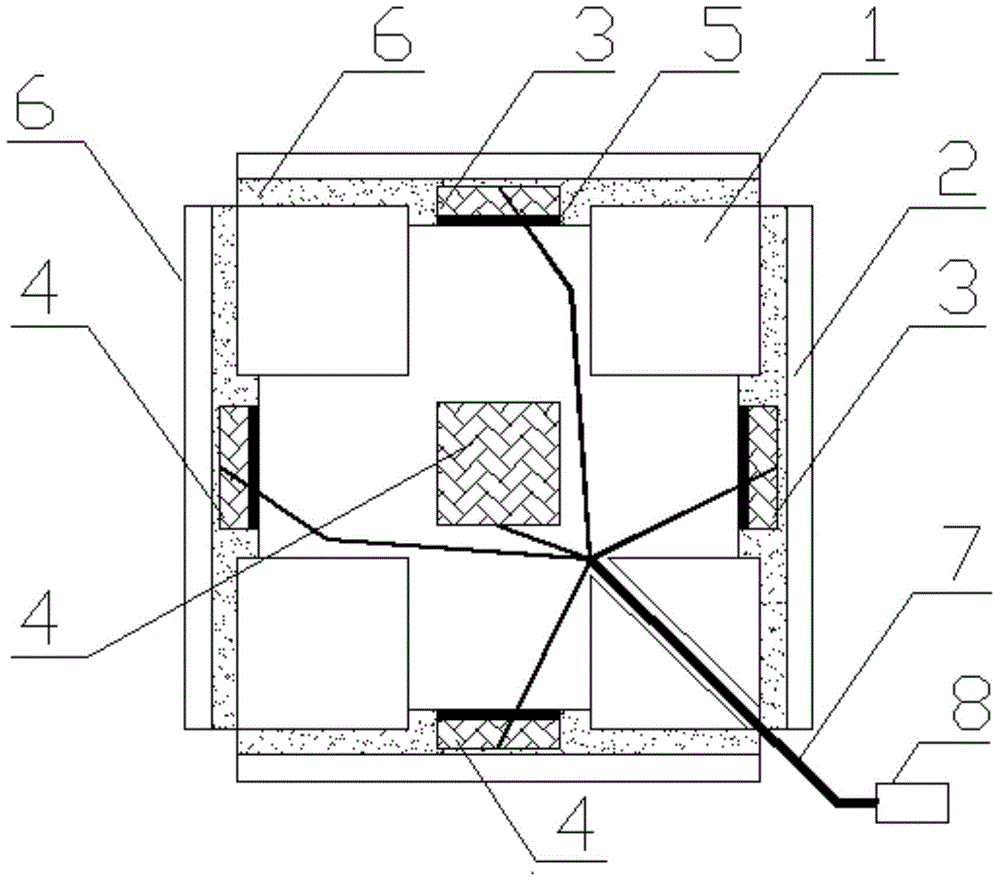

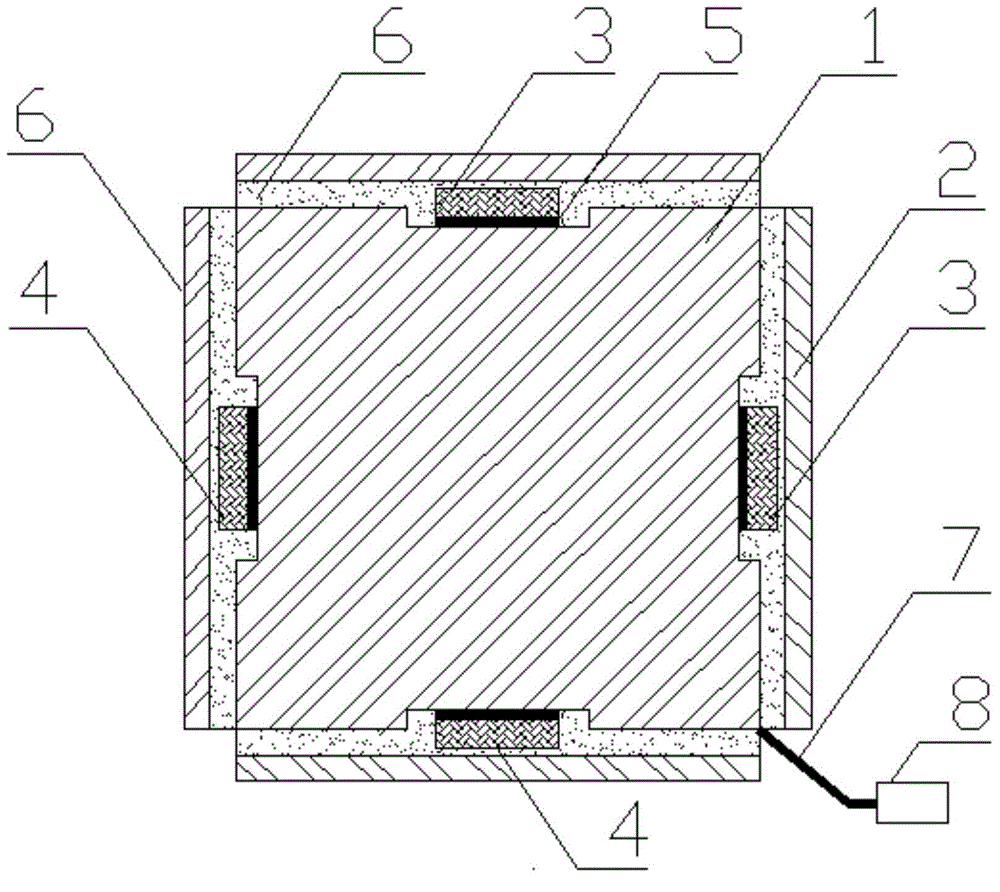

[0017] The implantable concrete three-dimensional space stress monitoring sensor of the present invention consists of a cubic metal core 1, a metal protective shell 2, a d33 type piezoelectric ceramic sheet 3, a d15 type piezoelectric ceramic sheet 4, AB glue 5, a high-strength epoxy resin insulating glue 6, Composed of three-core shielded wires 7 and shielded joints 8; three d33-type piezoelectric ceramic sheets 3 and three d15-type piezoelectric ceramic sheets 4 are pasted on the six outer surfaces of the cubic metal core 1; three d33-type piezoelectric ceramic sheets 3 and three d15 type piezoelectric ceramic sheets 4 are pasted symmetrically; the piezoelectric ceramic sheets are pasted on the cubic metal core 1 with AB glue 5; the six outer surfaces of the cubic metal core 1 and the piezoelectric ceramic sheets are coated with high-strength epoxy Resin insulating gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com