Method for synthesizing and purifying lithium bis(oxalato)borate

A bisoxalate lithium borate and synthesis method technology, which is applied in the field of synthesis and purification of bisoxalate lithium borate, can solve the problems of long time consumption and difficulty in industrial production, and achieve the effects of convenient operation and control, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

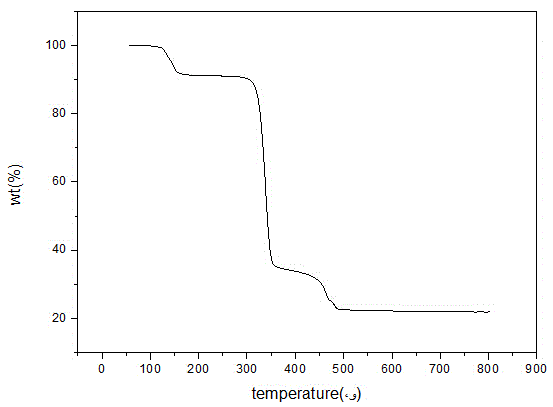

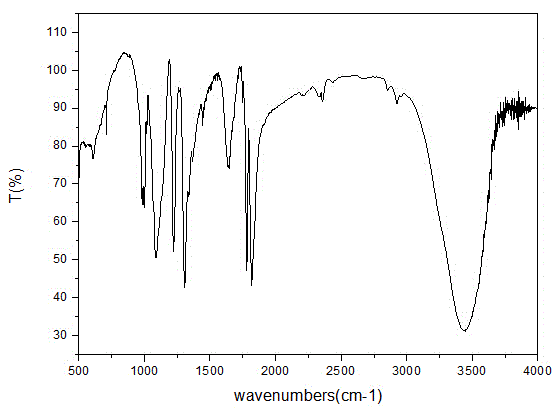

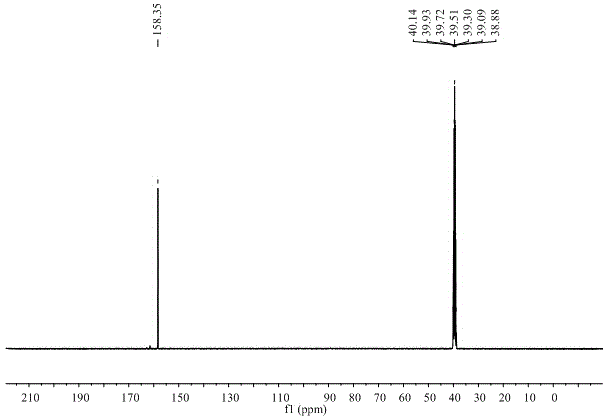

[0027] Example 1: A method for synthesizing lithium bisoxalate borate, comprising the following steps: dispersing 63.04g of oxalic acid, 11.97g of lithium hydroxide and 30.92g of boric acid in 300mL of xylene, adding 200g of zirconium beads, fully ball milling and mixing for 3 h at normal temperature and pressure . After the reaction, the solution was filtered with suction, and the obtained solid mixture was placed in a vacuum drying oven, and the temperature was gradually raised to 120° C. for 8 h to obtain 53.4 g of a crude product.

[0028] Further, for the purification method of lithium bisoxalate borate, dissolve the above-mentioned crude product in 500mL acetone to saturation, filter to remove insoluble matter and zirconium beads; At this time, a large number of crystals were precipitated in the bottle; the solution after atmospheric distillation was suction-filtered, and the crystals were washed with cyclohexane for 3 times, and the crystals were dried in a vacuum env...

Embodiment 2

[0029] Example 2: A method for synthesizing lithium bisoxalate borate, comprising the following steps: dispersing 31.52g of oxalic acid, 5.99g of lithium hydroxide and 15.46g of boric acid in 150mL of benzene, adding 150g of zirconium beads, and fully ball milling and mixing for 5 hours at normal temperature and pressure. After the reaction, the solution was filtered with suction, the obtained solid mixture was placed in a vacuum drying oven, the temperature was raised to 120°C step by step, and after drying for 12 hours, 27.8 g of crude product was obtained.

[0030] Further, for the above method of purifying lithium bisoxalate borate, dissolve the crude product in 250mL of acetonitrile to saturation, filter to remove insoluble matter and zirconium beads; then add benzene to the saturated solution until precipitation occurs, and distill out acetonitrile under reduced pressure. A large number of crystals were precipitated in the bottle; the solution after vacuum distillation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com