Ammonium sulfamate demulsifier, synthesis method thereof and application of ammonium sulfamate in cold rolling of waste emulsion

A technology of demulsifier and ammonium sulfonate, applied in the field of physical chemistry, can solve the problems of low demulsification efficiency and achieve the effects of high demulsifier yield, less side reactions and high demulsification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

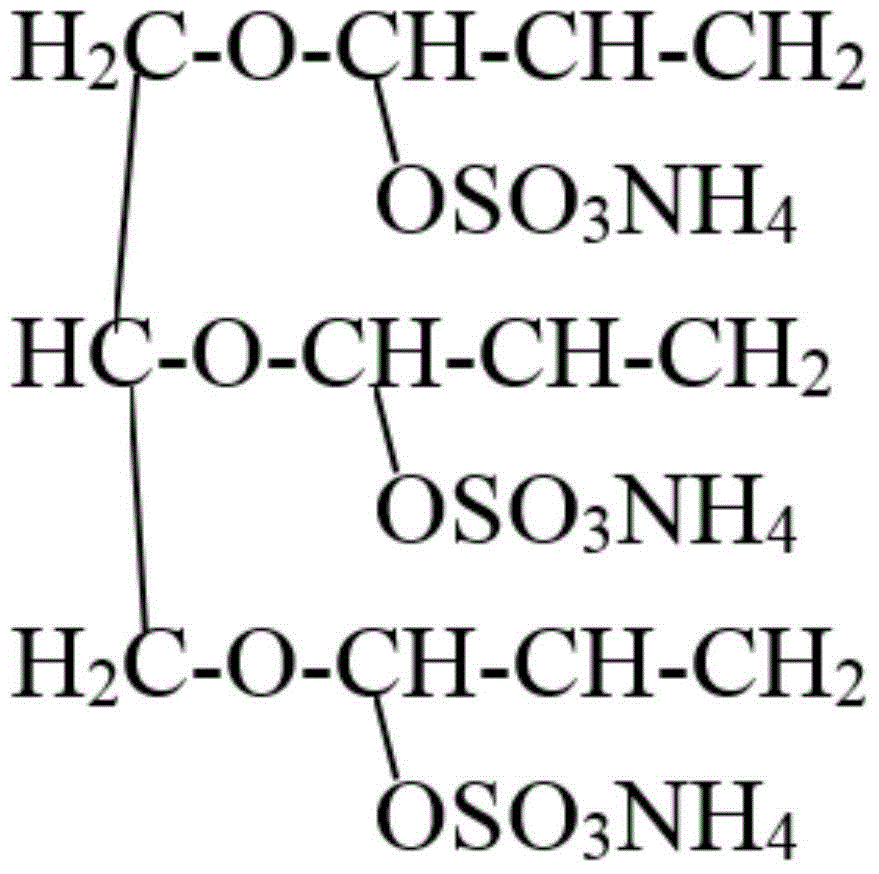

[0017] The preparation steps of cold rolling waste emulsion demulsifier of the present invention are as follows:

[0018] 1) Take 500ml of glycerol in a beaker, slowly heat to 50°C, and then add 200ml of boron trifluoride ether;

[0019] 2) After slowly adding 55ml of epichlorohydrin to the above reaction system, the reaction continued for 8 hours;

[0020] 3) After the above reaction is finished, allow the reaction system to cool down to room temperature naturally;

[0021] 4) Add 55 ml of ethanol solution of sodium hydroxide dropwise to the above reaction system, and allow the reaction system to react at room temperature for 7 hours;

[0022] 5) After the reaction finishes, the reaction system is cooled to room temperature, and filtered to remove solids, which are mainly sodium chloride solids;

[0023] 6) the filtrate is put int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com