A production process and device for comprehensive recycling of α-alkenyl electrostatic acid

An electrostatic acid and alkenyl technology, which is applied in the production process and device field of comprehensive recycling of α-alkenyl electrostatic acid, can solve the problem that the neutralization heat cannot be well utilized, the by-product sultone is contained, and the difficult sultone Complete hydrolysis of esters and other problems, to achieve the effects of stable and controllable neutralization heat release, reduced energy consumption, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

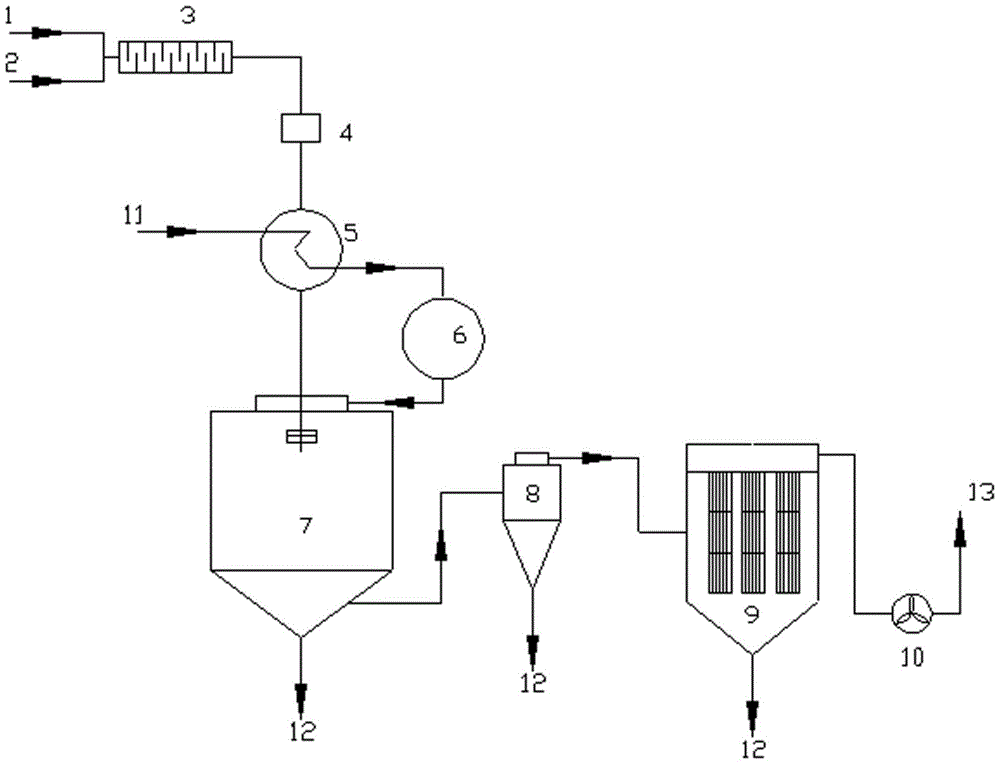

[0039] The electrostatic acid and 32% liquid caustic soda produced in the production process of organic material α-olefin and sulfur trioxide sulfonation enter the static mixer at the same time. The weight ratio of electrostatic acid to liquid caustic soda is 1:1, and the two are fully in the static mixer. Mix and neutralize, and control the pressure of the material in the static mixer to reach 0.5Mpa (the temperature after neutralization is 120℃) through the back pressure valve, enter the heat exchanger and exchange heat with the dry air, then cool to 60℃, and then enter the rotary spray drying Device. At the same time, the dry air is heated up to 90°C through the heat exchanger, and then heated to 130°C through an air heater to enter the rotary spray dryer. After the mixture is atomized into droplets, it is contacted with hot air in the downstream direction to finally obtain a granular product with a solid content of 94.8%, an active substance of 32%, a pH of 9.3, and a parti...

Embodiment 2

[0042] The electrostatic acid and 32% liquid caustic soda produced in the production process of organic material α-olefin and sulfur trioxide sulfonation enter the static mixer at the same time. The weight ratio of electrostatic acid to liquid caustic soda is 1:1, and the two are fully in the static mixer. Mix and neutralize, and control the pressure of the material in the static mixer to reach 0.5Mpa (the temperature after neutralization is 120°C) through the back pressure valve, enter the heat exchanger and exchange heat with the dry air, then cool to 70°C, and then enter the spray dryer. At the same time, the dry air is heated up to 85°C through the heat exchanger, and then heated to 130°C through an air heater to enter the spray dryer. After the mixture is atomized into droplets, it is contacted with hot air in the downstream direction to finally obtain a granular industrial additive with a solid content of 98.3%, an active substance of 31%, a pH of 8.3, and a particle size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com