Process for removing thallium from thallium-containing heavy metal wastewater through neutralization and flocculation

A technology for heavy metals and heavy metal ions, applied in the fields of neutralizing water/sewage treatment, water pollutants, water/sewage treatment, etc., can solve the problem of high chromaticity of wastewater, and achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

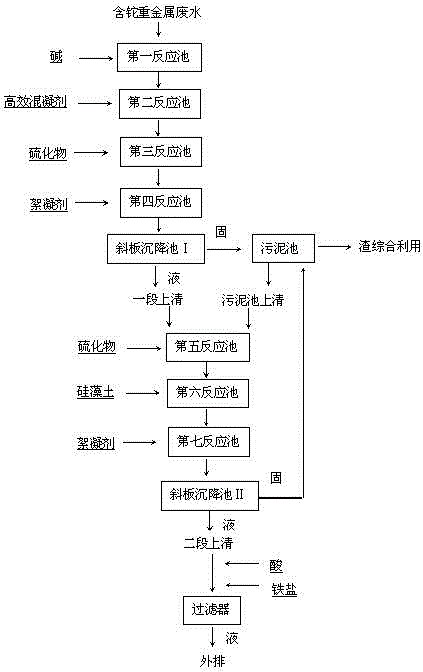

[0019] A process for neutralizing and coagulating thallium-containing heavy metal wastewater, which is characterized in that the thallium-containing heavy metal wastewater is used as the treatment object, and the secondary treatment of the wastewater ensures that thallium and heavy metal elements are discharged up to the standard. Its specific process includes:

[0020] 1) The primary treatment part includes: adding one or more of lime milk, sodium hydroxide or limestone to the first reaction tank for heavy metal wastewater containing thallium, adjusting the pH to 9-11, so that the Tl 3+ with OH - Forms insoluble Tl(OH) 3 ,OH - Form hydroxide precipitation with most heavy metal ions under alkaline conditions; add one or more high-efficiency flocculants among aluminum sulfate, polyaluminum chloride, and polyaluminum sulfate in the second reaction tank to promote hydroxide precipitation Form larger alum flowers; add one or more of sodium sulfide, ammonia sulfide, potassium su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com