Lead anode plate low-temperature casting process

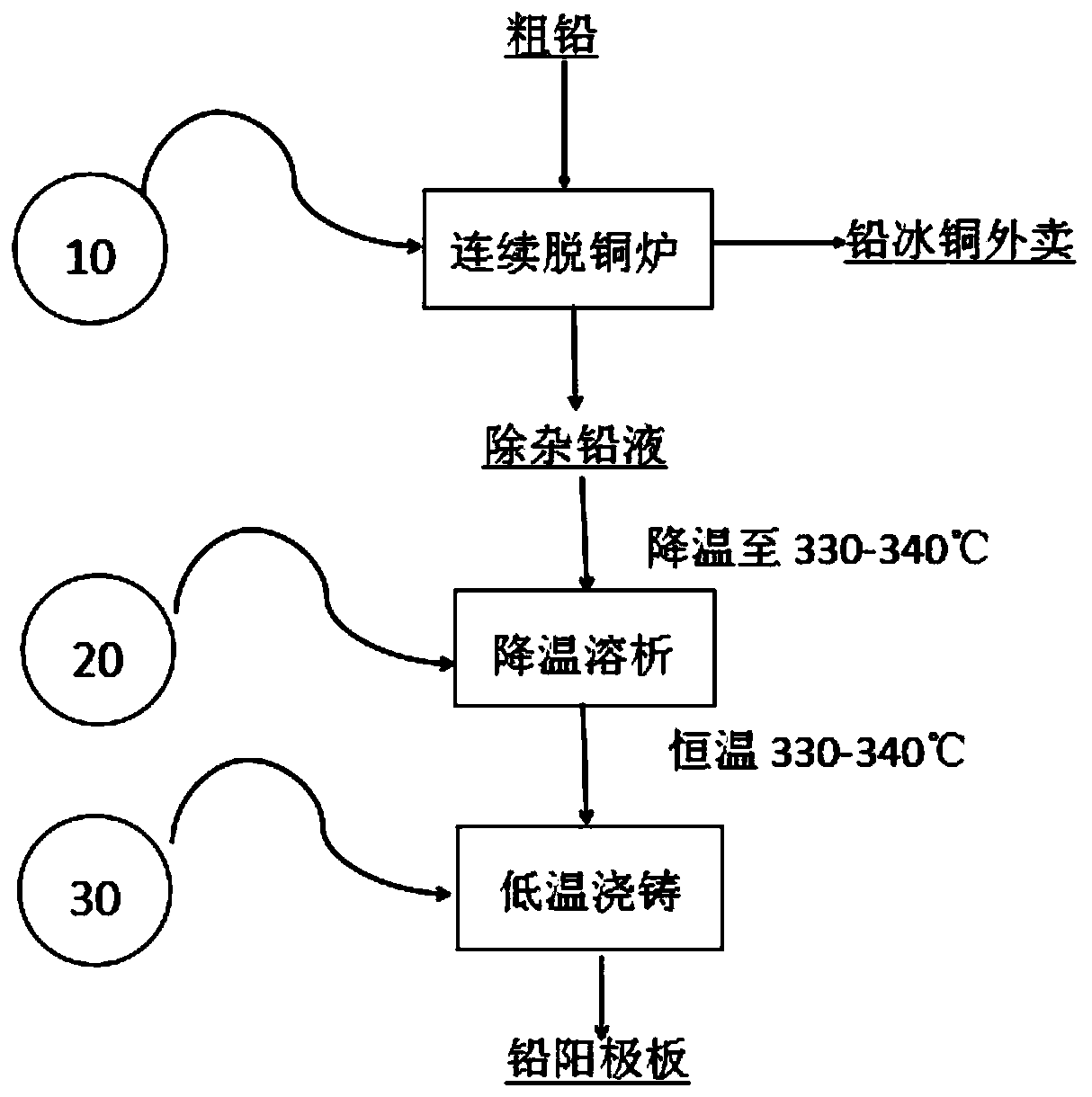

A lead anode and plate low-temperature technology, which is applied in the field of lead fire smelting, can solve the problems of affecting the current efficiency of lead electrolysis, affecting economic benefits, and incomplete copper removal, so as to avoid foamed lead, improve purity, and eliminate foamed lead.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add crude lead liquid to the continuous decopper furnace, add sulfur according to the calculation of copper content in lead liquid, obtain lead matte and lead liquid for removing impurities, lead liquid for removing impurities contains less than 1wt% copper, then cool the lead liquid for removing impurities to Carry out elution and decopper at 330°C, the obtained copper-free lead solution contains 0.065wt% copper, then keep the temperature at 330°C, and perform casting to obtain a lead anode plate containing less than 0.04wt% copper, and no lead foam is produced during the casting process.

Embodiment 2

[0039] Add crude lead liquid to the continuous decopper furnace, add sulfur according to the calculation of copper content in lead liquid, obtain lead matte and lead liquid for removing impurities, lead liquid for removing impurities contains less than 1wt% copper, then cool the lead liquid for removing impurities to Carry out elution and decopper at 335°C, and the obtained copper-removing lead solution contains 0.067wt% copper, and then keep the temperature at 335°C, and perform casting to obtain a lead anode plate containing less than 0.04wt% copper, and no lead foam is generated during the casting process.

Embodiment 3

[0041] Add crude lead liquid to the continuous decopper furnace, add sulfur according to the calculation of copper content in lead liquid, obtain lead matte and lead liquid for removing impurities, lead liquid for removing impurities contains less than 1wt% copper, then cool the lead liquid for removing impurities to Carry out elution and decopper at 340°C, the obtained copper-free lead solution contains 0.07wt% copper, then keep the temperature at 340°C, and perform casting to obtain a lead anode plate containing less than 0.05wt% copper, and no lead foam is produced during the casting process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com