A kind of natural high crystallinity plant cellulose and preparation method thereof

A plant cellulose, high crystallinity technology, applied in fiber raw material processing, pulping with acid salts/acid anhydrides, textiles and papermaking, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

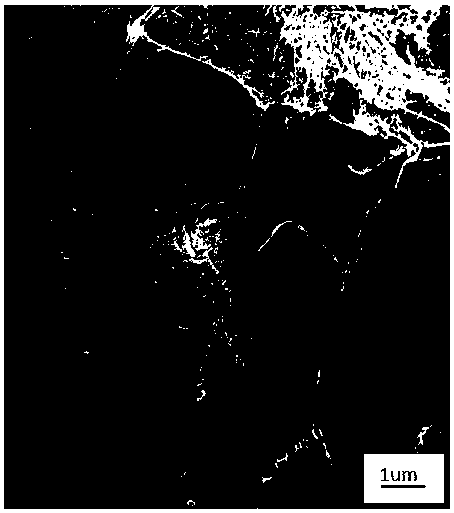

Image

Examples

Embodiment 1

[0026] Clean the green algae taken from freshwater lakes to remove impurities, air-dry them naturally, and grind them mechanically to obtain green algae powder. According to the solid-liquid ratio of 1:5 (w / w), the amount of sodium hypochlorite is 10% (w / w) of the green algae powder, and the green algae powder (5.0 g) and sodium hypochlorite (0.5 g) are placed in acetic acid with a pH of 4.0 - In sodium acetate buffer solution, the temperature is 40°C, and the reaction is continuously stirred for 3 h. After the reaction is finished, the green algae powder changes from green to milky white, washed to neutral, and solid-liquid separation. The separated solid residue is further placed in sodium hydroxide solution to remove protein, the solid-liquid ratio is 1:8 (w / w), the amount of sodium hydroxide is 10% (w / w) of the solid residue, the temperature is 50°C, Stirring was continued for 4 h. After the reaction, the reaction solution was washed to neutral, and the solid and liquid ...

Embodiment 2

[0029] Clean the green algae raw material taken from the river, remove impurities, air-dry naturally, and mechanically grind to obtain the green algae powder. According to the solid-liquid ratio of 1:10 (w / w), the amount of sodium hypochlorite is 20% (w / w) of the green algae powder, and the green algae powder (4.0 g) and sodium hypochlorite (0.8 g) are placed in acetic acid with a pH of 4.5 - In sodium acetate buffer solution, the temperature is 55°C, and the reaction is continuously stirred for 4.5 h. After the reaction is finished, the green algae powder changes from green to milky white, washed to neutral, and solid-liquid separation. The separated solid residue is further placed in sodium hydroxide solution to remove protein, the solid-liquid ratio is 1:10 (w / w), the amount of sodium hydroxide is 25% (w / w) of the solid residue, and the temperature is 70°C. Stirring was continued for 6 h. After the reaction, the reaction solution was washed to neutral, and the solid and l...

Embodiment 3

[0031] Clean the green algae raw material taken from shallow sea waters, remove impurities, air-dry naturally, and grind mechanically to obtain green algae powder. According to the solid-to-liquid ratio of 1:20 (w / w), the amount of sodium hypochlorite is 40% (w / w) of the green algae powder, and the green algae powder (5.0 g) and sodium hypochlorite (2.0 g) are placed in acetic acid with a pH of 5.0 - In sodium acetate buffer solution, the temperature is 70°C, and the reaction is continuously stirred for 6 h. After the reaction is finished, the green algae powder changes from yellow-green to milky white, washed to neutral, and solid-liquid separation. The separated solid residue is further placed in sodium hydroxide solution to remove protein, the solid-liquid ratio is 1:12 (w / w), the amount of sodium hydroxide is 15% (w / w) of the solid residue, the temperature is 60°C, Stirring was continued for 5 h. After the reaction, the reaction solution was washed to neutral, and the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com