Technology for removing thallium with lead and zinc smelting flue gas washing waste acid water

A technology for polluted acid wastewater and smelting flue gas, which is applied in gaseous discharge wastewater treatment, water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as complex processes and achieve good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

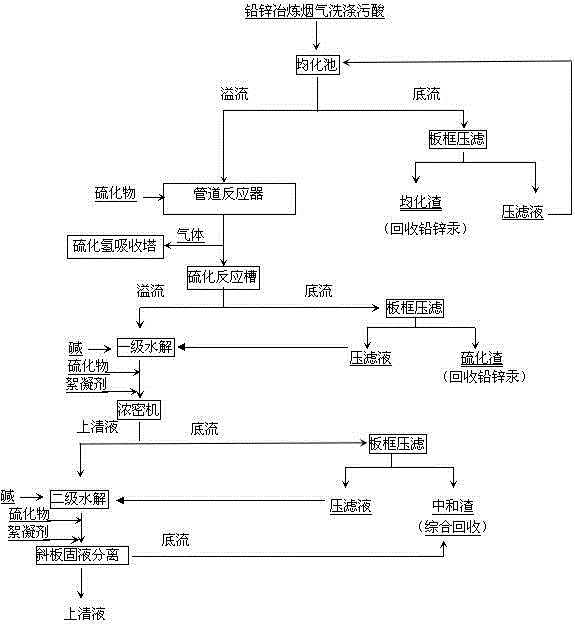

Image

Examples

Embodiment Construction

[0020] The invention provides a treatment process for washing dirty acid waste water with flue gas from lead-zinc smelting. The technological process is to settle the flue gas washing dirty acid waste water into the homogenization tank, and then add the prepared vulcanizing agent from the pipe connecting the supernatant of the homogenization tank to the vulcanization reaction tank, so that the vulcanizing agent and the dirty acid can be fully and evenly mixed and reacted. The amount of vulcanizing agent used is 5-10 times the amount calculated by the chemical reaction formula of the mercury content in the polluted acid. Mercury removal is continued in the vulcanization reaction pool, and the reaction time is controlled to be no less than 1 hour.

[0021] After mercury removal, the polluted acid wastewater and the bottom flow filtrate after mercury removal enter the primary treatment part, and the pH value is adjusted to about 9 through calcium carbide mud, so that the Tl 3+ wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com