A method for concentrating high-concentration brine

A concentrated brine and concentrated water technology, applied in general water supply conservation, chemical instruments and methods, water/sewage multi-stage treatment, etc. The effect of reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

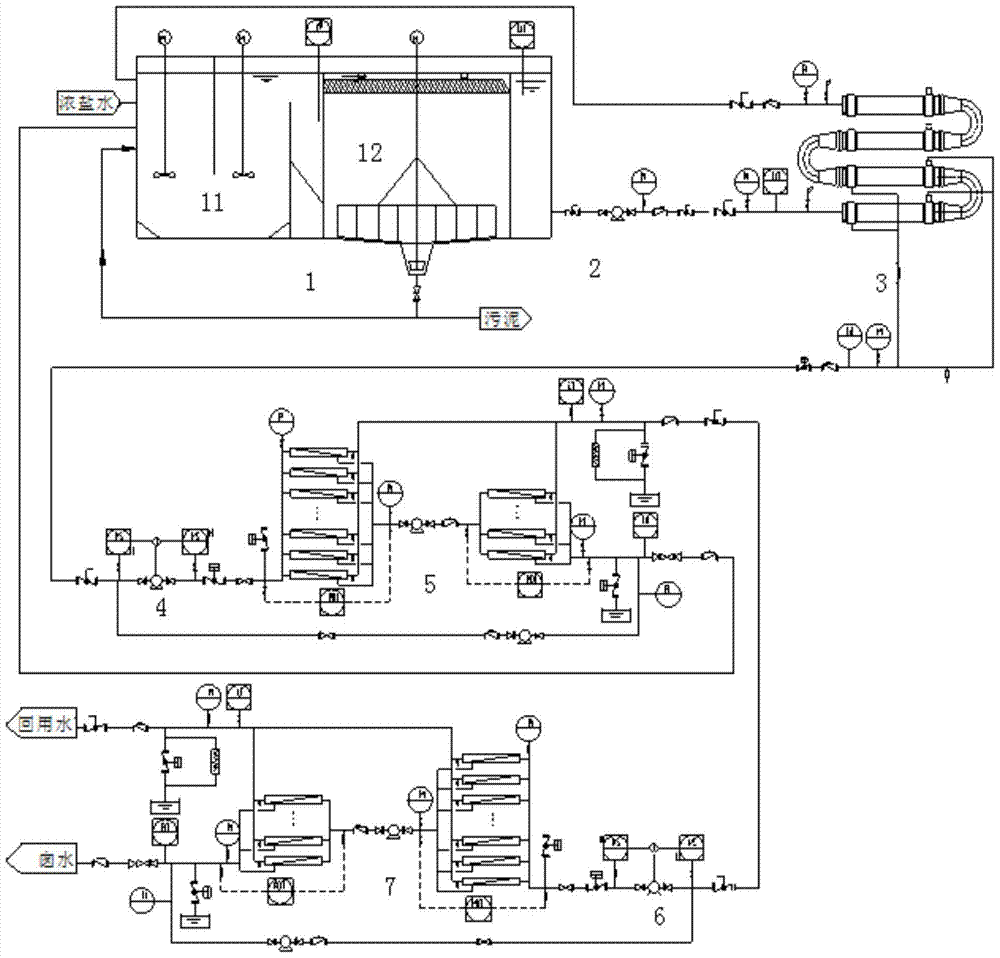

[0023] The method flow chart of the present invention (highly concentrated brine concentration method) is as follows figure 1 shown.

[0024] figure 1 Among them, the present invention is a fully automatic control method, which is mainly composed of 1-circulating high-efficiency precipitation, 2-circulating pump, 3-circulating ultrafiltration, 4-nanofiltration feed pump, 5-nanofiltration, 6-high-salt reverse osmosis feed pump, 7- It is composed of high-salt reverse osmosis and other units, and each area is closely connected, and is equipped with a mixer and a sludge pump.

[0025] The main material of the device of the present invention is carbon steel for anti-corrosion, the internal epoxy coal tar pitch paint is anti-corrosion three times, the external epoxy coal tar pitch paint is twice applied, and the topcoat is applied twice.

[0026] The concentrated brine first enters the stirring zone of the circulating high-efficiency sedimentation zone. The water inlet adopts a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com