Olivary porous stannic oxide sensitive to hydrogen sulfide as well as preparation and application

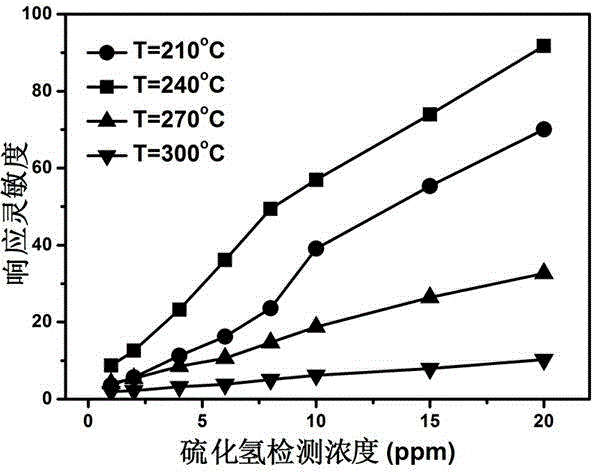

An olive-shaped, hydrogen sulfide technology, applied in tin oxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as cost and practicability limit application, achieve a simple and feasible preparation scheme, and ensure personnel safety. , good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

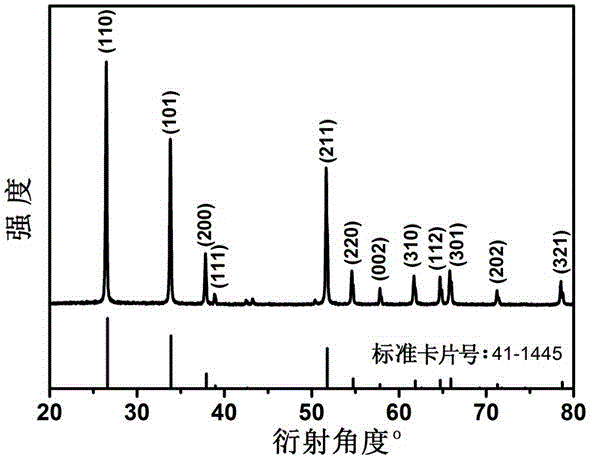

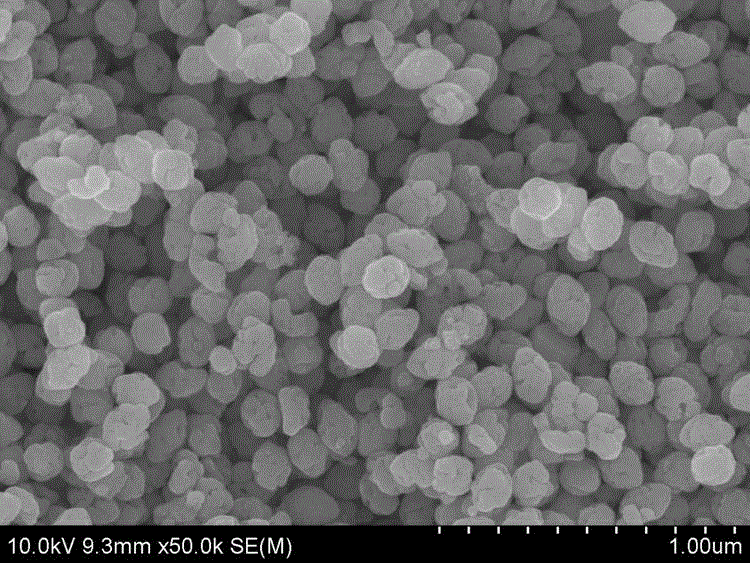

[0024] A kind of "olive shape" porous SnO 2 The preparation method of nanoparticle, its step is as follows:

[0025] (1) Weigh the surfactant polyvinylpyrrolidone (k=30) and polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (its molecular formula is: PEO-PPO-PEO), 0.4 g and 0.8 g respectively, dissolved in 60 ml of deionized water and ethanol solution with a volume ratio of 1:3, completely dissolved by magnetic stirring and the solution was clear;

[0026] (2) Weigh 0.226 g and 1.8 g of tin chloride tetrahydrate and oxalic acid dihydrate with a molar ratio of 1:20 respectively, dissolve in (1) to clarify the solution, and magnetically stir to dissolve completely;

[0027] (3) Pour the solution of the above step (2) into a 100 ml Teflon hydrothermal reaction kettle, place the reaction kettle in a constant temperature blast dryer, raise it from room temperature to 180°C, and heat it at 180°C Cool down naturally after keeping for 12 hours;

[0028] (...

Embodiment 2

[0037] A kind of "olive shape" porous SnO 2 The preparation method of nanoparticle, its step is as follows:

[0038] (1) Weigh the surfactant polyvinylpyrrolidone (k=30) and polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (its molecular formula is: PEO-PPO-PEO), 0.4 g and 0.8 g respectively, dissolved in 60 ml of deionized water and ethanol solution with a volume ratio of 1:3, completely dissolved by magnetic stirring and the solution was clear;

[0039] (2) Weigh 0.226 g and 0.9 g of tin chloride tetrahydrate and oxalic acid dihydrate with a molar ratio of 1:10 respectively, dissolve in (1) to clarify the solution, and magnetically stir to dissolve completely;

[0040] (3) Pour the solution of the above step (2) into a 100 ml Teflon hydrothermal reaction kettle, place the reaction kettle in a constant temperature blast dryer, raise it from room temperature to 180°C, and heat it at 180°C Cool down naturally after keeping for 12 hours;

[0041] (...

Embodiment 3

[0045](1) Weigh the surfactant polyvinylpyrrolidone (k=30) and polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (its molecular formula is: PEO-PPO-PEO), 0.4 g and 0.8 g respectively, dissolved in 60 ml of deionized water and ethanol solution with a volume ratio of 1:3, completely dissolved by magnetic stirring and the solution was clear;

[0046] (2) Weigh 0.226 g and 2.7 g of tin chloride tetrahydrate and oxalic acid dihydrate with a molar ratio of 1:30 respectively, dissolve in (1) to clarify the solution, and magnetically stir to dissolve completely;

[0047] (3) Pour the solution of the above step (2) into a 100 ml Teflon hydrothermal reaction kettle, place the reaction kettle in a constant temperature blast dryer, raise it from room temperature to 180°C, and heat it at 180°C Cool down naturally after 12 hours;

[0048] (4) After the reaction is over, centrifuge the light yellow precipitate in (3) to obtain the product, and wash it with absolut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com