AgInSe2 nanocrystalline and preparation method thereof

A nanocrystal and precursor solution technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of unenvironmental protection, cumbersome, complicated operation process, etc., and achieve short synthesis cycle, good repeatability, and technological process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 1) Preparation of precursor solution

[0031] mixing silver nitrate, indium chloride and / or indium chloride tetrahydrate, selenium dioxide, polyvinylpyrrolidone and dimethylformamide as raw materials and stirring evenly to obtain a precursor solution;

[0032] 3) Compounding of nanocrystals

[0033] Put the precursor solution obtained according to step 1) into an autoclave, react at a constant temperature of 160-220°C for 3-20 hours, centrifuge the reacted solution and collect the solid, wash and dry the obtained solid with a solvent, that is Get AgInSe2 Nanocrystalline;

[0034] When selecting indium chloride tetrahydrate in step 1), the mass ratio between raw materials is silver nitrate: indium chloride tetrahydrate: selenium dioxide: polyvinylpyrrolidone=30~37:53~64:60~110:200~2000 , Of course, when choosing indium chloride, its dosage can be converted by the above mass ratio. Oleic acid can also be added to the raw materials in step 1) and mixed and stirred evenl...

Embodiment 1

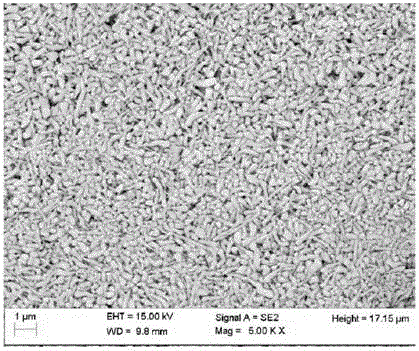

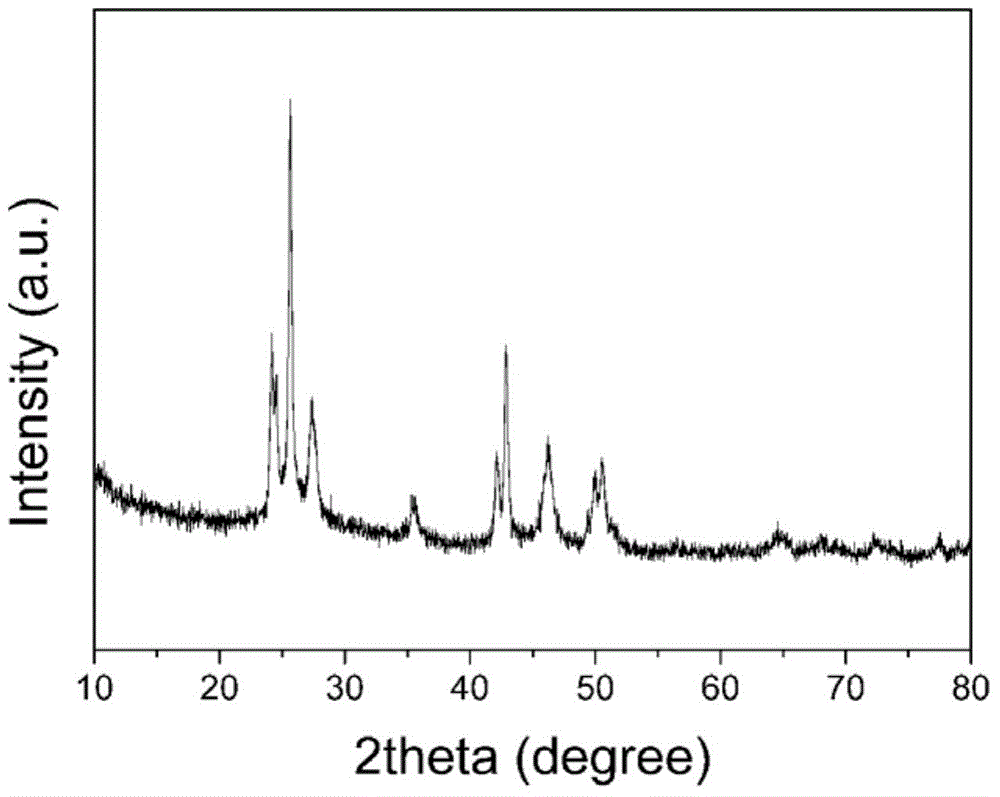

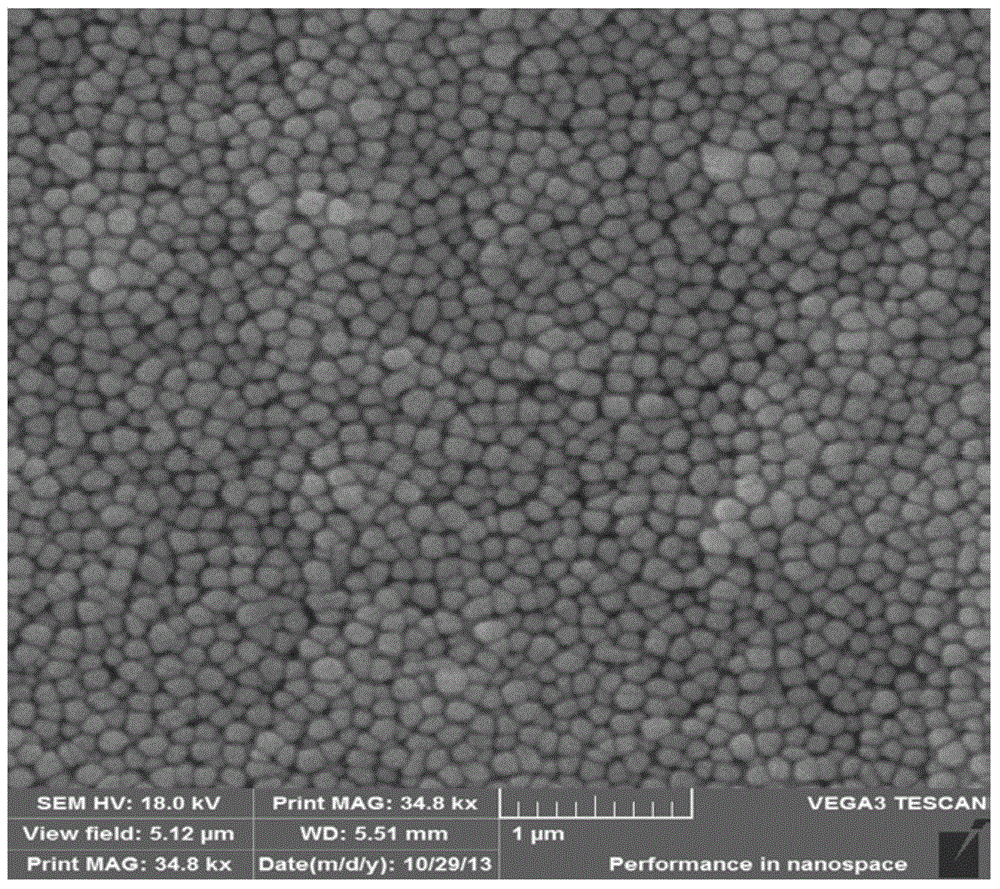

[0039] First, 34mg of silver nitrate, 60mg of indium chloride tetrahydrate, 88.8mg of selenium dioxide and 1g of polyvinylpyrrolidone (PVP) were added to 25mL of oleic acid and 10mL of dimethylformamide to form a mixed solution, and the above mixed solution was stirred for 40 minutes , to form a precursor solution; then add the precursor solution into a 50mL high-pressure reactor lined with tetrafluoroethylene, seal the reactor and place it in a programmed temperature-controlled oven for reaction at a temperature of 200°C. The time is 12 hours. After the reaction is over, after the reaction kettle is naturally cooled to room temperature, open the reaction kettle, take out the tetrafluoroethylene liner, and then carry out centrifugation on the reaction solution to collect the reaction product, and then use deionized water, ethanol, etc. to clean and centrifuge several times, and finally dried in a vacuum oven at 60°C for 4 hours to obtain AgInSe 2 Nanocrystals, which are solub...

Embodiment 2

[0041] First, 34mg of silver nitrate, 60mg of indium chloride tetrahydrate, 88.8mg of selenium dioxide and 0.5g of PVP were added to 25mL of oleic acid and 10mL of dimethylformamide, and stirred for 40 minutes to form a precursor solution; then the precursor solution was added Into a 50mL tetrafluoroethylene-lined autoclave. After sealing the kettle body, place it in a programmed temperature-controlled oven for reaction, set the reaction temperature to 200° C., and the reaction time to 12 hours.

[0042] After the reaction is over, cool the reaction kettle to room temperature naturally, open the reaction kettle, take out the tetrafluoroethylene liner, then centrifuge the reaction solution to collect the reaction product, and wash the reaction product with deionized water, ethanol, etc. successively. Centrifuge several times, and finally dry in a vacuum oven at 60°C for 4 hours to obtain AgInSe 2 Nanocrystalline, which is soluble in water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com