Numerical control turning ultra-hard blade with V-shaped cubic boron nitride cutting units

A cubic boron nitride, superhard insert technology, applied in cutting inserts, turning equipment, tools for lathes, etc., can solve the problems of difficult to guarantee surface quality and accuracy, affecting insert life, large cutting resistance, etc., and achieve heat conduction. Satisfy the performance and cooling effect, increase the overall welding area, and increase the cutting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

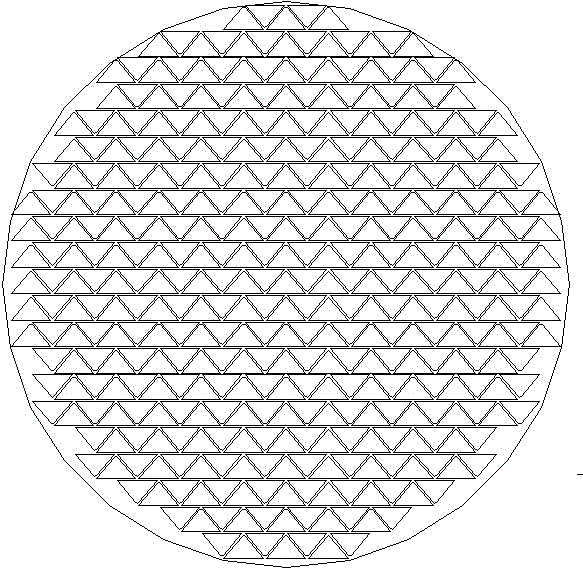

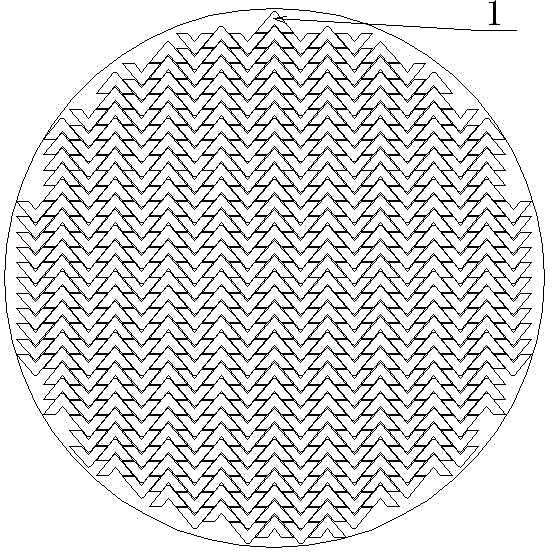

[0037]The CNC turning superhard insert with V-shaped cubic boron nitride cutting unit is composed of cemented carbide substrate welding cubic boron nitride cutting unit, the cubic boron nitride cutting unit is V-shaped cubic boron nitride cutting unit, hard alloy There are two acute angles on the upper and lower end surfaces of the base body, and each acute angle has a V-shaped cubic boron nitride cutting unit. The hard alloy base is provided with V-shaped protrusions, and the V-shaped cubic boron nitride cutting unit It straddles the V-shaped protrusion, and the inner wall of the V-shaped cubic boron nitride cutting unit is attached to the V-shaped protrusion. The edge angle α of the V-shaped cubic boron nitride cutting unit is consistent with the acute angle of the cemented carbide substrate. The included angle β of the inner wall of the V-shaped cubic boron nitride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com