Hydrophobic organic solid acid catalyst and preparation method thereof

An organic solid, catalyst technology, applied in organic chemistry, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problem that small specific surface area affects the application of effective acid catalysts, and the yield of HMF cannot be obtained. Improve the stability of HMF, etc., to achieve the effects of easy recovery, high permeability and low density, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

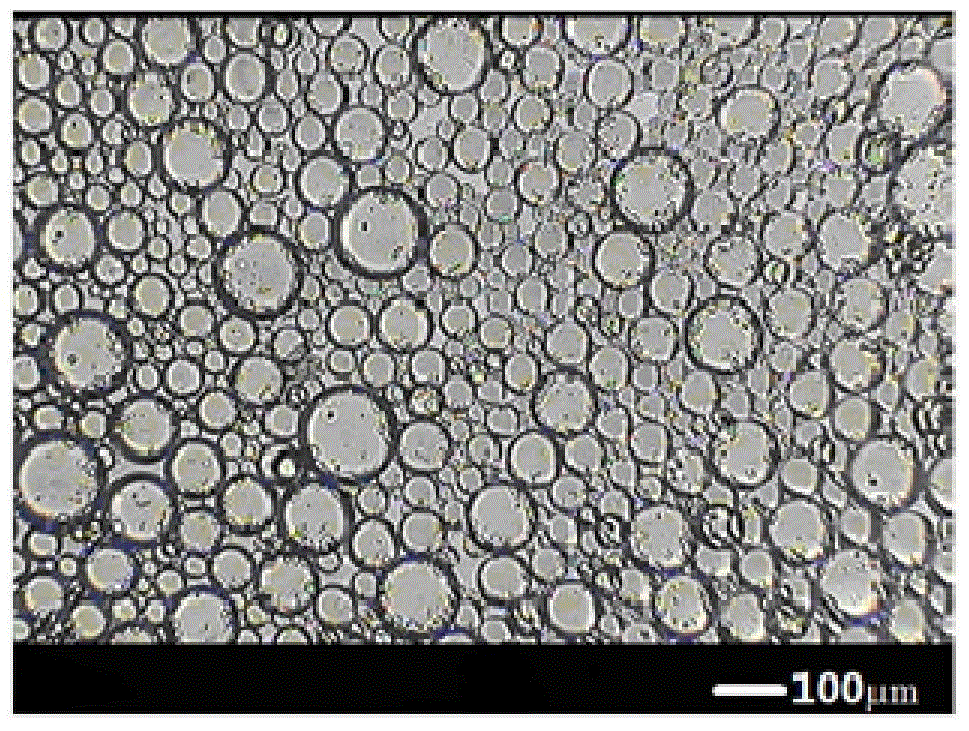

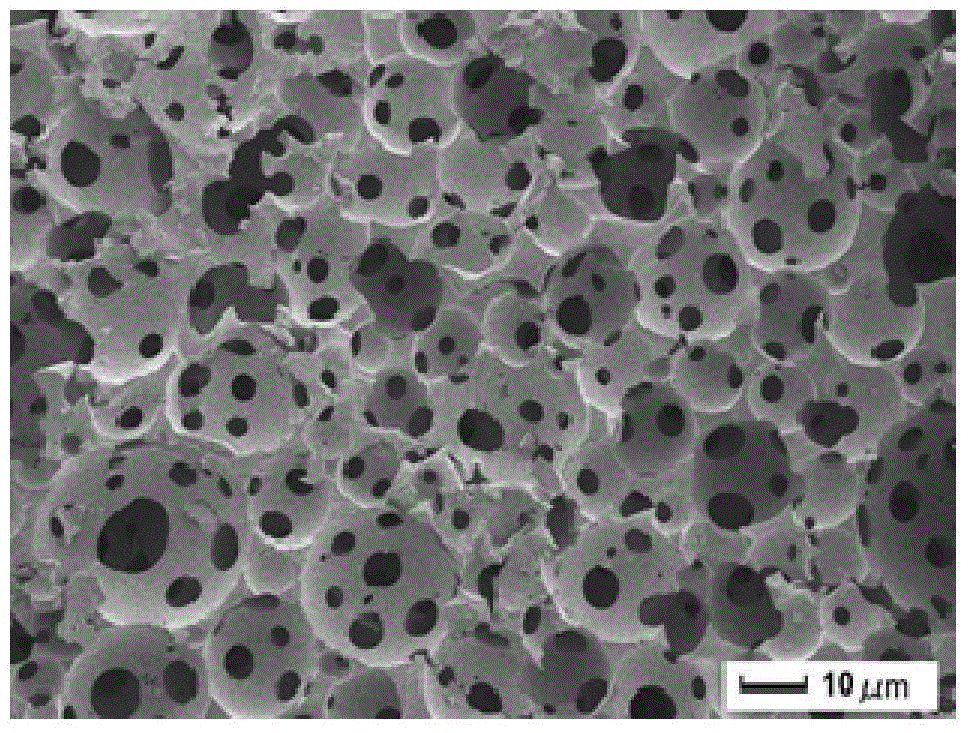

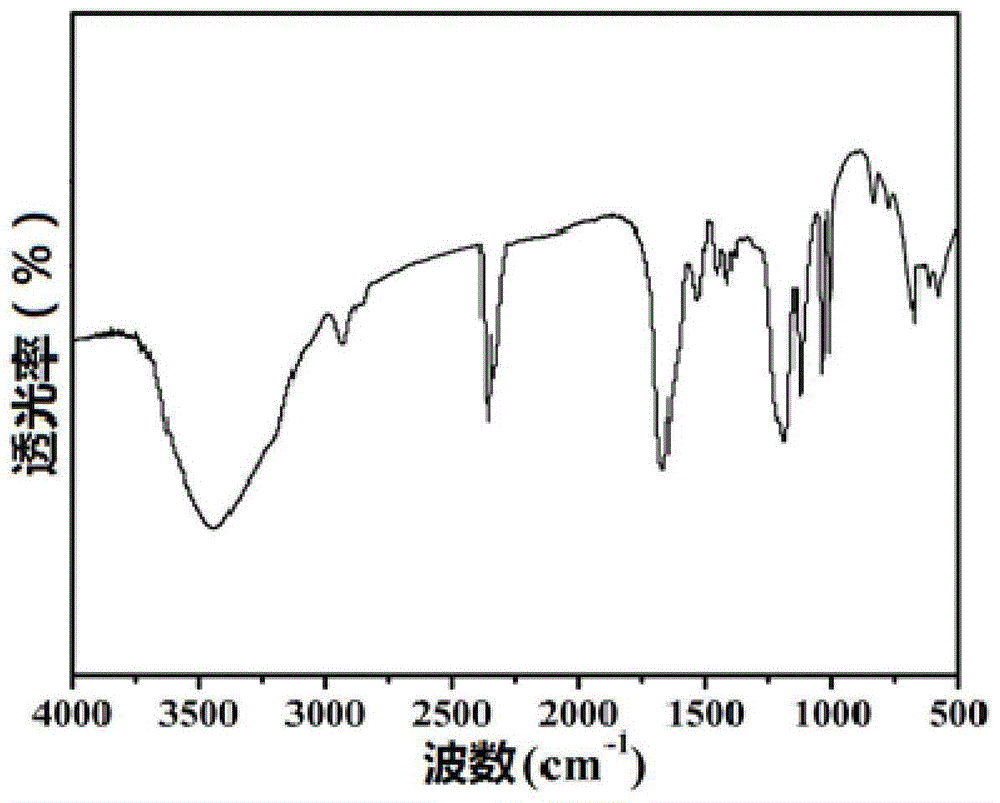

[0031] (1) Preparation of organic solid hydrophobic acid catalyst

[0032] Add 1.08g of sodium p-phenylacesulfonate (SS), 0.03g of ammonium persulfate, 0.0258g of N,N-methylenebisacrylamide, and 0.028g of Span-20 into 3.256mL of deionized water to form a mixed solution as water phase, stirred for 20-30min to make it evenly mixed; take 18.45mL of paraffin as the oil phase, add the oil phase to the water phase drop by drop under constant stirring and mix to prepare a stable high internal phase emulsion system (HIPEs); stir After 10 to 20 minutes, the emulsion was kept at 60°C for 18 hours for thermally initiated polymerization; the obtained polymer was extracted with acetone to elute the surfactant and paraffin, and the product was dried at 50 to 55°C for 20 to 24 hours under vacuum to obtain a large Porous organic solid polymers;

[0033] Configure a 1.5mol / mL hydrochloric acid solution, grind 0.38g of the material obtained in the previous step into powder, and then add 50mL o...

Embodiment 2

[0050] (1) Preparation of organic solid hydrophobic acid catalyst

[0051] Add 1.2g SS, 0.04g potassium persulfate, 0.0309g N,N-methylenebisacrylamide, 0.04g Tween-85 into 4mL deionized water to form a mixed solution as the water phase, stir for 20-30min to mix Uniform; take 22.67mL paraffin as the oil phase, add the oil phase to the water phase drop by drop under constant stirring and mix to prepare stable HIPEs; after stirring for 10-20min, the emulsion is kept at 65°C for 21h for thermally initiated polymerization ; The obtained polymer is subjected to Soxhlet extraction with acetone to elute the surfactant and paraffin, and the product is dried under vacuum at 50-55°C for 20-24 hours to obtain a macroporous organic solid polymer;

[0052] Configure 1mol / mL sulfuric acid solution, then, after grinding 0.5g of the material obtained in the previous step into powder, add 50mL of 1mol / mL H 2 SO 4 solution, stirred for 22 hours, and vacuum-dried at 70-80°C to obtain a macropor...

Embodiment 3

[0061] (1) Preparation of organic solid hydrophobic acid catalyst

[0062] Add 1.32g SS, 0.05g azobisisobutylamidine hydrochloride, 0.036g N,N-methylenebisacrylamide, 0.052g fatty acid methyl ester polyoxyethylene ether to 4.744mL deionized water to form a mixed solution As the water phase, stir for 20-30 minutes to make it evenly mixed; take 26.88mL paraffin as the oil phase, and add the oil phase to the water phase drop by drop under constant stirring to prepare stable HIPEs; after stirring for 10-20 minutes, The emulsion is kept at 80°C for 24h for heat-initiated polymerization; the obtained polymer is extracted with acetone to elute the surfactant and dodecane, and the product is dried under vacuum at 55°C for 20-24h to obtain a macroporous organic solid polymer ;

[0063] Configure 2.5mol / mL nitric acid solution, then, after grinding 0.62g of the material obtained in the previous step into powder, add 50mL of 1.22mol / mL H 2 SO 4 solution, stirred for 24 hours, and vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com