Wheat blossom midge soil removal, rinsing and sorting device and use method thereof

A wheat midge and sorting device technology, applied in chemical instruments and methods, botany equipment and methods, applications, etc., can solve problems such as high work intensity, low efficiency, cumbersome process, etc., to save physical labor, improve efficiency, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

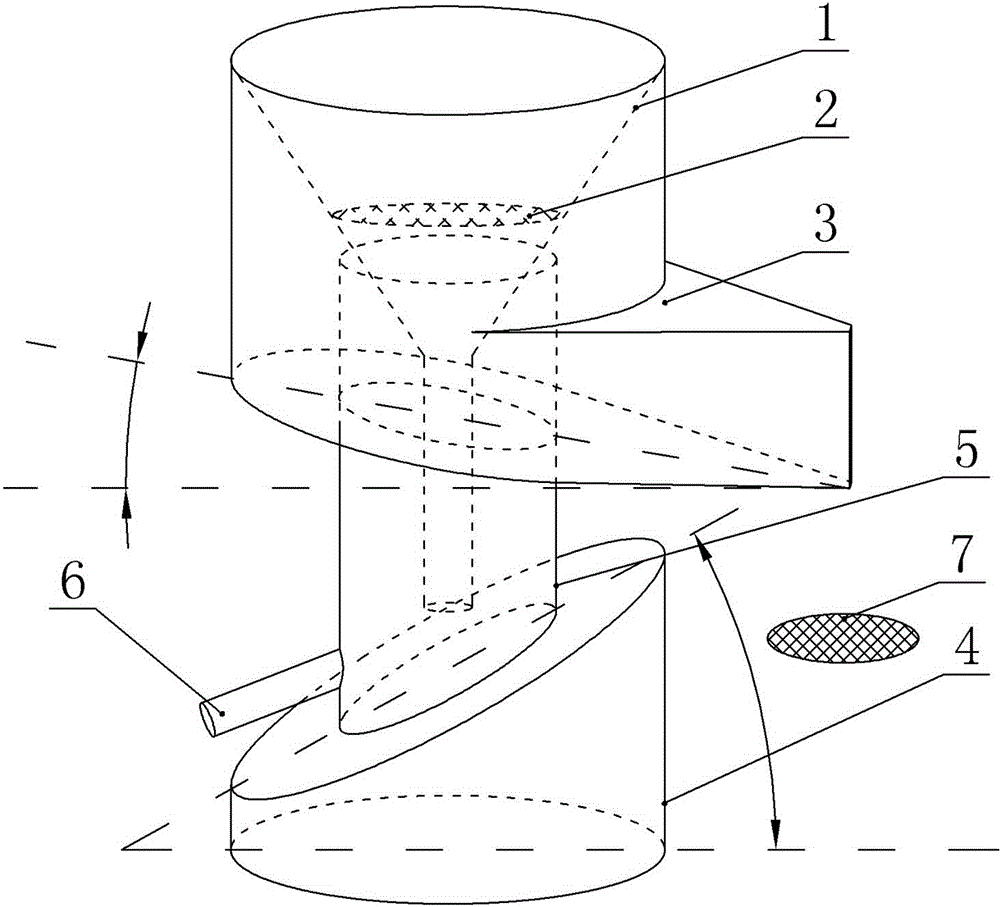

[0030] Embodiment one: if figure 1 As shown, in the present embodiment, a wheat midge soil washing, rinsing, and sorting device includes a hopper 1, an overflow tank 3, a rinse irrigation and a midge receiving screen 7, and the rinse irrigation includes a main irrigation 4 and a main irrigation The casing 5 at the top, the main irrigation is a cylindrical bottle with a diameter of 200 mm, the top of the main irrigation 4 is a slope, the lowest point of the slope is 50 mm away from the bottom of the bottle, and the center of the slope is connected with a cylindrical casing 5 with a diameter of 100 mm. The height is 320 mm, and the base of the casing 5 is provided with a water outlet 6; the upper part of the overflow tank 3 is an open cylindrical structure, the upper edge of the overflow tank 3 is fastened with the hopper 1, and the bottom surface of the overflow tank 3 is an inclined plane. One side of the column at the bottom of the overflow tank 3 is also provided with a poi...

Embodiment 2

[0040] Embodiment two: if figure 1 As shown, this embodiment is basically the same as Embodiment 1, except that the angle between the bottom surface of the overflow tank 3 and the horizontal plane is 30°, and the angle between the slope at the top of the main tank 4 and the horizontal plane is 45°. , the material of the hopper 1 is plexiglass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com