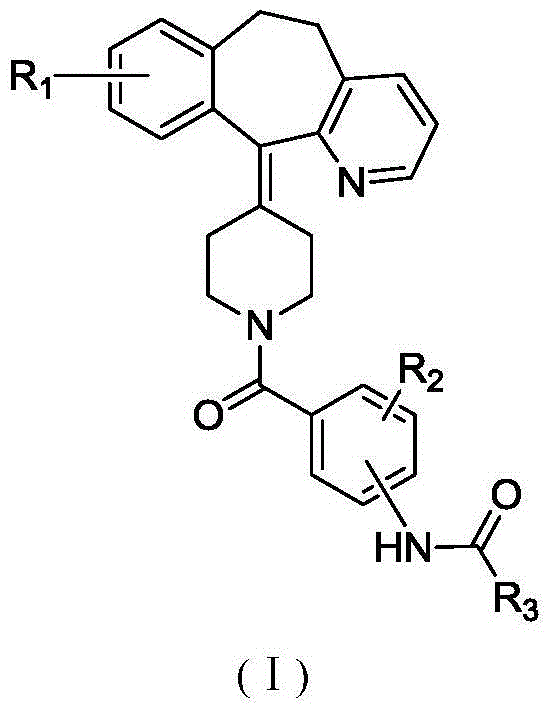

Bisamide compounds as well as preparation method and use thereof

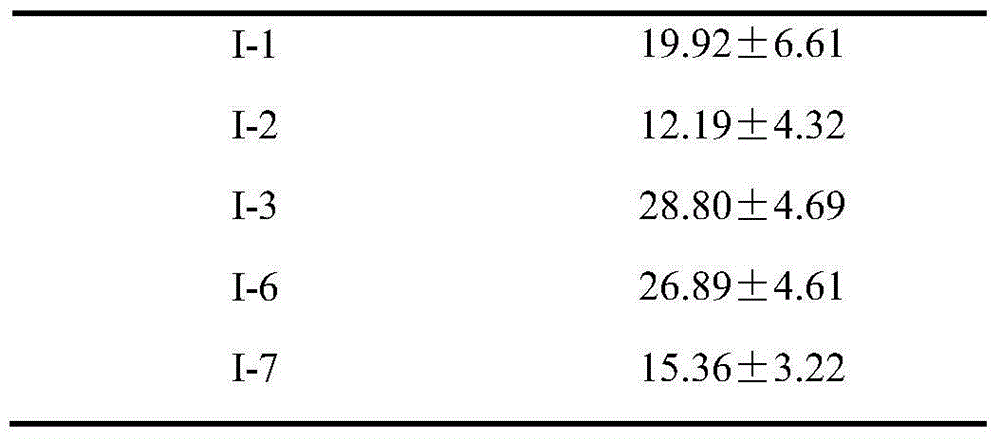

A compound and low-level technology, applied in the field of medicine, can solve the problems of insufficient physical and chemical properties of benzoazepine compounds such as activity and side effects, and achieve obvious antagonistic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

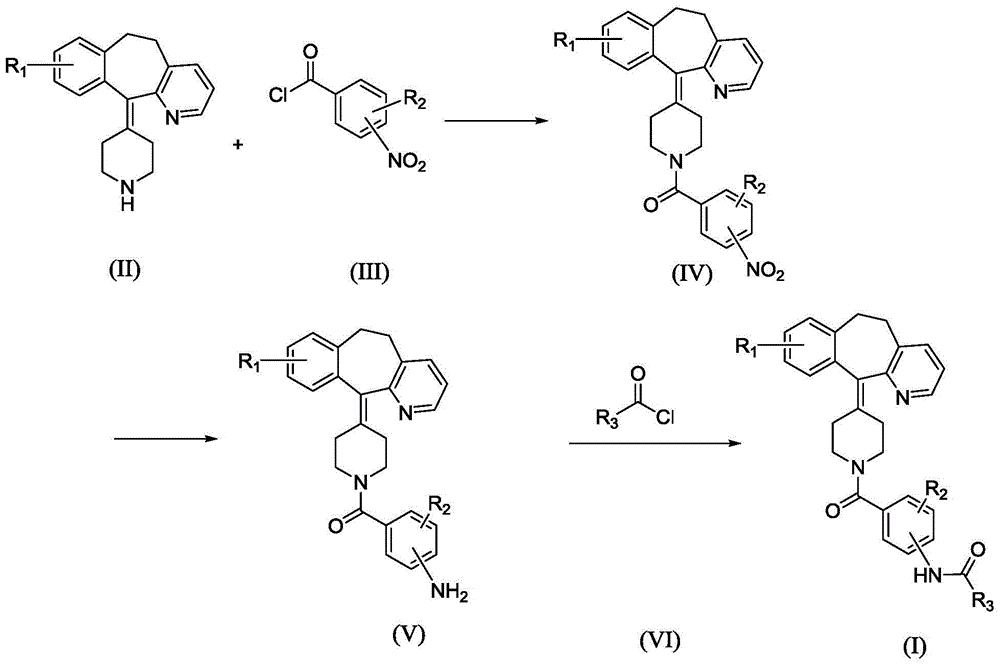

Method used

Image

Examples

Embodiment 1

[0055]

[0056] II-1 (100g, 322mmol) was placed in a 2000mL reaction bottle, and CH was added 2 Cl 2 (1000mL) stirred to dissolve, added triethylamine (50g, 490mmol), stirred at room temperature, added intermediate III-1 (59.8g, 322mmol) in batches, kept the temperature and stirred for 8h, TLC detection showed that the reaction was completed ( Developing agent ethyl acetate:petroleum ether=1:3).

[0057] The reaction solution was poured into 500ml of cold water, fully shaken to separate the layers, and the organic layer was separated and washed three times in succession. The organic layer was dried over anhydrous sodium sulfate and left overnight. After filtration, the solvent was evaporated to dryness under reduced pressure to obtain a light yellow solid crude product. The obtained crude product was recrystallized from ethanol to obtain 140.2 g of light yellow solid. Purity 98.9% (HPLC normalization method), yield 94.7%. ESI-MS: 460.1.

Embodiment 2

[0059]

[0060] II-1 (20g, 64mmol) was placed in a 250mL reaction bottle, and CHCl was added 3 (100mL) stirred to dissolve, added pyridine (7.8g, 98mmol), stirred at 50°C, added intermediate III-2 (12.5g, 67mmol) in batches, kept the temperature and stirred for 5h, TLC detection showed that the reaction was complete (expanded Agent ethyl acetate: petroleum ether = 1:3).

[0061] The reaction solution was poured into 100ml of cold water, fully shaken to separate the layers, and the organic layer was separated and washed three times in succession. The organic layer was dried over anhydrous sodium sulfate and allowed to stand overnight. After filtration, the solvent was evaporated to dryness under reduced pressure to obtain a light yellow solid crude product. The obtained crude product was purified by silica gel column chromatography to obtain 23.7 g of a white solid. The purity is 99.9% (HPLC normalization method), and the yield is 80.6%. ESI-MS: 460.1.

Embodiment 3

[0063]

[0064] Put II-2 (20g, 72mmol) in a 250mL reaction flask, add pyridine (60mL), stir to dissolve, stir at -5°C, add intermediate III-3 (15.2g, 76mmol) in batches, keep the temperature and stir After 24 hours, TLC detection showed that the reaction was complete (developing agent ethyl acetate:petroleum ether=1:3).

[0065] The reaction solution was poured into 300ml of cold water, stirred, and solids were precipitated. After filtering, the filter cake was washed with water and dried to obtain a yellow crude product. The crude product was recrystallized from ethanol to obtain 29.5 g of white solid. The purity is 98.3% (HPLC normalization method), and the yield is 93.1%. ESI-MS: 440.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com