Low-melting-point metal multi-dimensional structure liquid phase printing system and method

A low-melting-point metal and printing system technology, applied in the liquid phase printing method of multi-dimensional structure and its system field, can solve the problems of long solidification and forming time of structural parts, difficult printing process control, weak air cooling effect, etc., and achieve lifting speed and The scope of application, the temperature and flow field speed are convenient to adjust, and the effect of a wide range of sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

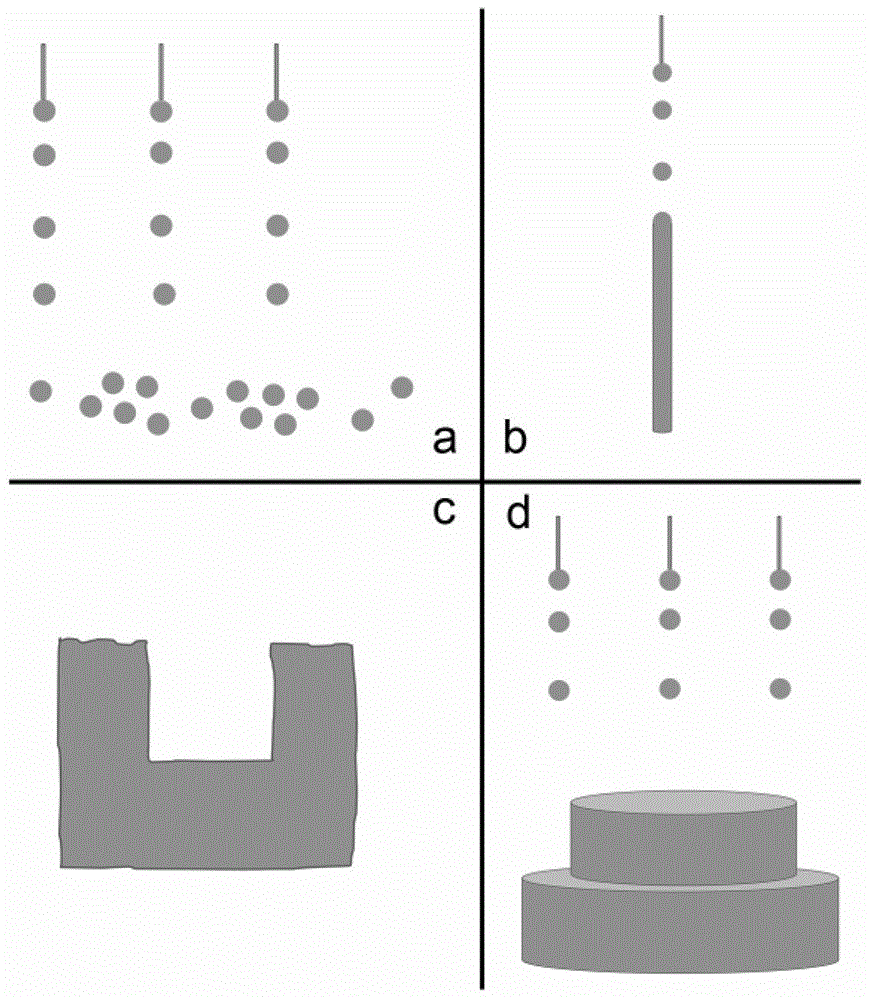

[0040] Example 1: Printing method of 0-dimensional metal structure

[0041] printing system such as figure 1. , including: a syringe pump array 1, an injection needle array 2, a liquid metal pool 3, a constant temperature box 4, a constant temperature bath 5 and a computer 6; the syringe pump array includes 2×2 syringe pumps arranged in a 2×2 array, and each syringe pump The inlet is connected to the liquid metal pool; the injection needle array includes 2×2 injection needles arranged in a 2×2 array, the injection needles are vertically opposite to the liquid surface of the constant temperature bath, and the liquid inlet of the injection needle is connected to the outlet end of the injection pump one by one connect. The syringe pump array 1, the injection needle array 2, the liquid metal pool 3, and the constant temperature bath 5 are all arranged in a constant temperature box; the computer is connected with the syringe pump array. In this embodiment, the needle is selected...

Embodiment 2

[0047] Embodiment 2: The multi-dimensional printing method of 1-dimensional metal structure

[0048] The system is as in Example 1.

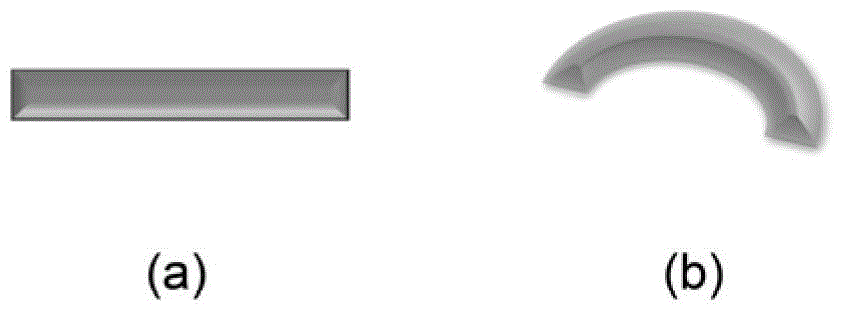

[0049] The 1D metal structure to be printed is a metal wire, and Bi is selected 31.6 In 48.8 sn 19.6 The alloy (melting point is 59°C) is the printing ink. The constant temperature box 4 is set at 80° C., the constant temperature water bath 5 is set at 45° C., and contains water. The syringe pump array includes 2×10 syringe pumps, arranged in a 2×10 array, and the inlet of each syringe pump is connected to the liquid metal pool; the injection needle array includes 2×10 injection needles, arranged in a 2×10 array, and the injection needles are connected to the constant temperature The liquid surface of the bath is vertically opposite, and the liquid inlet of the injection needle is connected with the outlet of the injection pump one by one. According to the diameter of the metal wire to be printed, the injection speed of the corresponding ne...

Embodiment 3

[0051] Embodiment 3 Multi-dimensional structure printing method of 2-dimensional metal structure

[0052] The system is as in Example 1.

[0053] The 2D metal structure to be printed is a "concave" metal surface, and Bi is selected 31.6 In 48.8 sn 19.6 The alloy (melting point is 59°C) is the stock solution. The constant temperature box 4 is set at 80° C., the constant temperature bath 5 is set at 45° C., and contains water. The syringe pump array includes 80×80 syringe pumps, arranged in a 2×2 array, and the inlet of each syringe pump is connected to the liquid metal pool; the injection needle array includes 80×80 injection needles, arranged in an 80×80 array, and the injection needles are connected to the constant temperature The liquid surface of the bath is vertically opposite, and the liquid inlet of the injection needle is connected with the outlet of the injection pump one by one.

[0054] Firstly, the structure to be printed is designed and the printing program is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com