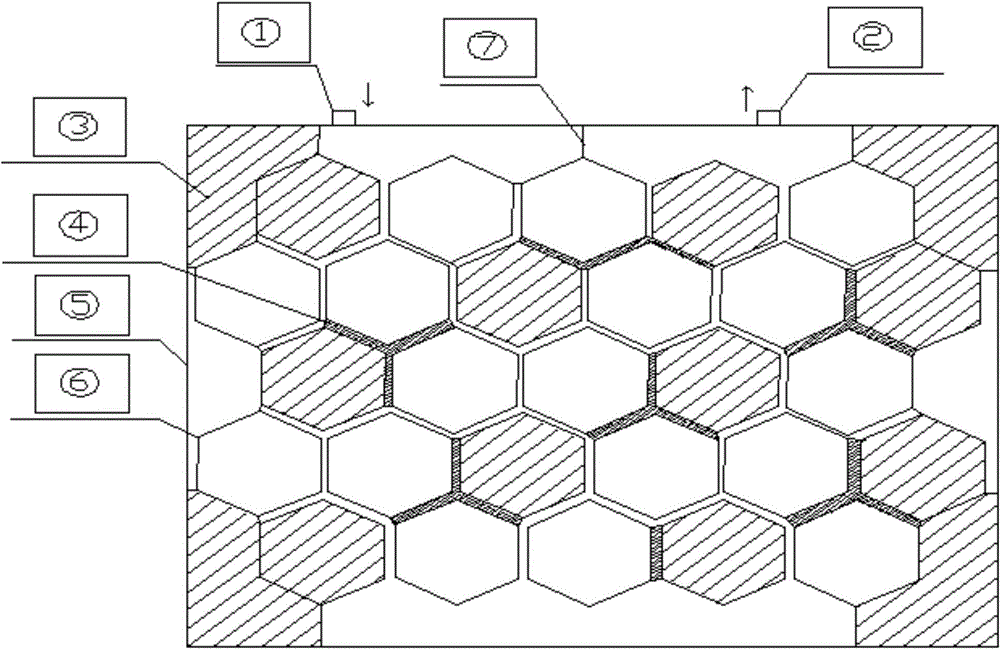

Temperature management device of power battery pack of electric automobile, as well as manufacture method and application method thereof

A technology for power battery packs and electric vehicles, applied in electric vehicle charging technology, electric vehicles, secondary batteries, etc., can solve the problems of high R&D, manufacturing costs, high starting temperature of batteries, and technical difficulties, and achieve heating Convenience, high cooling efficiency and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0062] Preferred embodiment one, such as image 3 As shown, when the car is running in a high-temperature environment, the temperature of the battery is also high when the ambient temperature is high. At this time, the battery will generate a temperature rise of about 15-20°C, and the entire battery will The local temperature in the bag will reach a risky state of 50-65°C. Of course, the temperature rise of various batteries varies, but the situation is similar. The battery must be radiated and cooled. At this time, the battery pack BMS detects a high temperature and sends a signal to the vehicle controller. The vehicle controller receives a high temperature digital signal and sends an open command to the control valve of the ⑨-thermal management system loop. At the same time - the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com