A circulating piston internal combustion engine with variable compression ratio and increased capacity

A variable compression ratio, piston-type technology, applied in the field of variable compression ratio and capacity-enhancing cyclic piston internal combustion engines, can solve the problems of low heat conversion efficiency, complex structure, low power liter of internal combustion engines, and avoid insufficient combustion and intake air. The effect of high efficiency and large air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

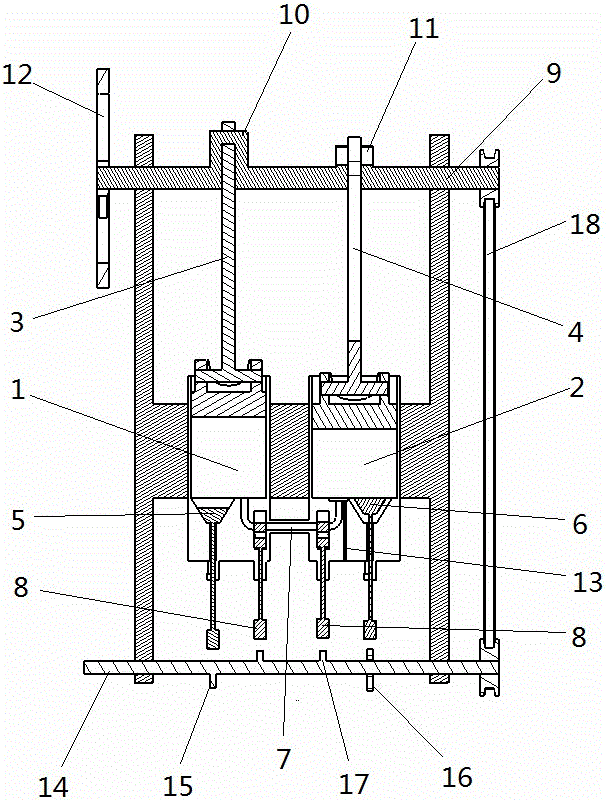

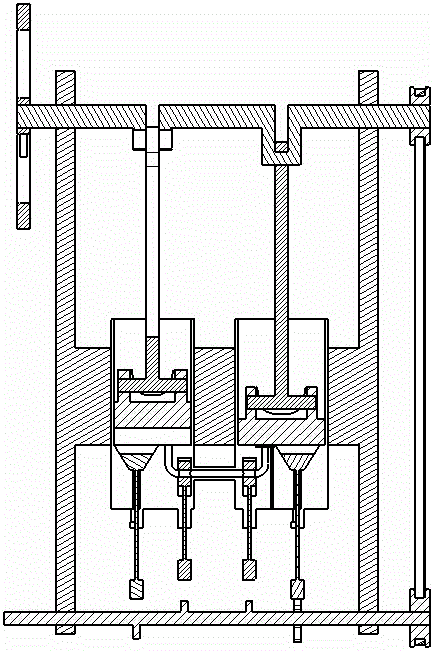

[0028] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] Such as figure 1 As shown, in the piston internal combustion engine with variable compression ratio and capacity increasing cycle of the present invention, the compressor cylinder piston mechanism 3 performs piston movement in the compressor cylinder 1, the working cylinder piston mechanism 4 performs piston movement in the working cylinder 2, and the crankshaft mechanism 9 synchronizes Control the air cylinder piston mechanism 3 and the working cylinder piston mechanism 4, the first crank structure 10 and the second crank structure 11 have an angle difference in the direction of rotation around the crank mechanism 9, and the inertial flywheel 12 provides inertia to drive the crank mechanism after the previous rotation 9 rotates, the compressed air cylinder 1 and the working cylinder 2 are connected by the cylinder connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com