Composite paper

A composite paper and paper layer technology, applied to composite paper. It can solve the problems of leaving paper scraps, low strength and poor natural texture, and achieve the effect of good wet strength, safety and comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention has no special limitation on the preparation method of the composite paper, which may be hot pressing method or ultrasonic method. The hot pressing method includes the following steps: stacking the paper layer and the reinforcement layer up and down to form a group, pressing rollers, forming bonding lines on the surface of the paper layer and the reinforcement layer by heating and pressing, so that the paper layer and the reinforcement layer are connected together .

[0034] The ultrasonic method includes the following steps: stack the paper layer and the reinforcing layer, use an ultrasonic generator to form ultrasonic waves in the area to be bonded, and under the action of the ultrasonic waves, the paper layer and the reinforcing layer will oscillate at high frequency to form a bonding pattern, and connect the Together.

[0035] Experimental results show that the wet breaking strength of the composite paper of the invention is greater than 3N / 15...

Embodiment 1

[0038] A composite paper is obtained by heating and pressing one layer of paper and one layer of reinforcing layer. The reinforcing layer is air-through non-woven fabric.

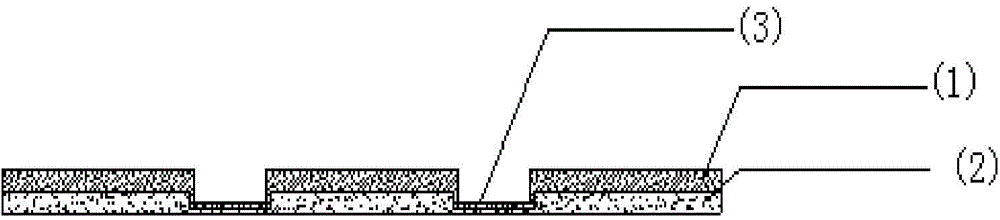

[0039] figure 1 A schematic cross-sectional view of the composite paper prepared for Example 1. figure 1 Among them, (1) is the paper layer, (2) is the reinforcement layer, and (3) is the single-side bonding grain.

[0040] The wet breaking strength of the obtained composite paper was measured, and the results showed that the wet breaking strength was 3.1N / 15mm.

Embodiment 2

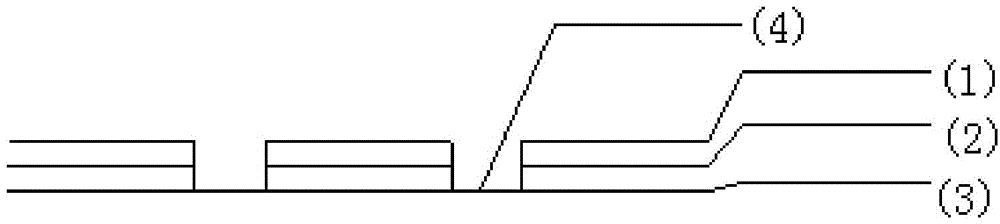

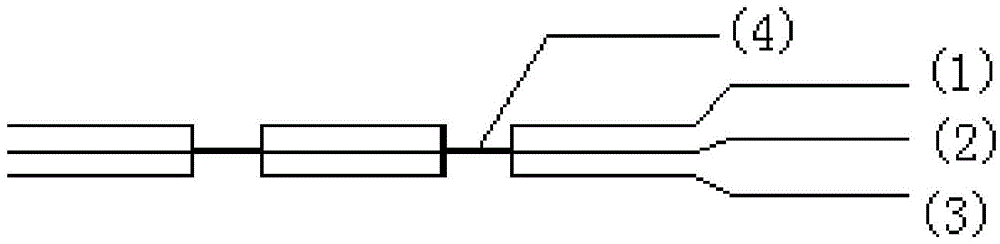

[0042] The first paper layer, the reinforcement layer, and the second paper layer are stacked in sequence, and subjected to ultrasonic vibration to obtain a composite paper with single-side bonded grain. The reinforcement layer is a polyethylene film.

[0043] figure 1 Schematic cross-sectional view of the composite paper prepared for Example 2. figure 2 Among them, (1) is the first paper layer, (2) is the reinforcement layer, (3) is the second paper layer, and (4) is the single-sided bonding grain.

[0044] The wet breaking strength of the obtained composite paper was measured, and the results showed that the wet breaking strength was 3.3N / 15mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com