Naringinase production method

A technology for naringinase and seeds, applied in the field of naringinase production, can solve the problems of low immobilization efficiency, complicated equipment, limited application, etc., and achieve the improvement of aroma components, production of food additives, high enzyme production level, and improved flavor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

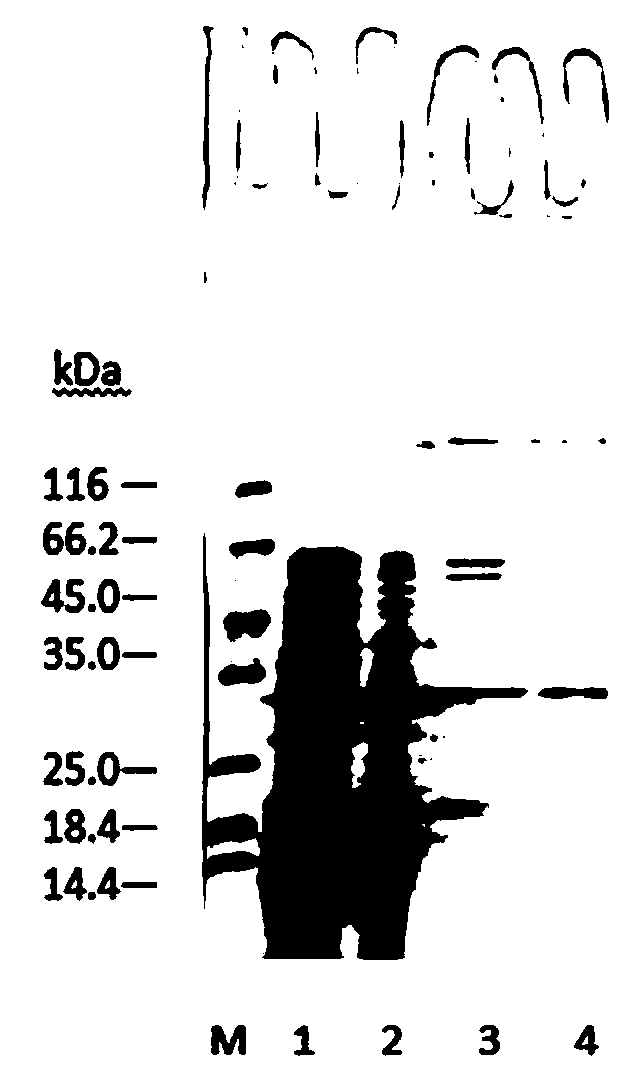

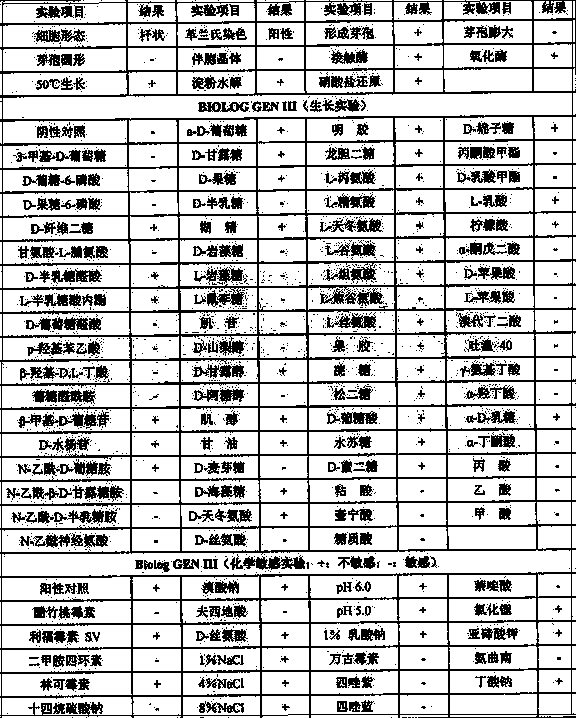

[0048] Example 1 Decadence and identification of Symblysis 11568 Screening

[0049] 1. JNU002 (BACILLUS AMYLOLOLOLIQUEFACINES) 11568 screening separation

[0050] Called 2G to collect soil -like or moldy or / and pomelo skin from all over the country. It oscillates 30min in a 100ml taper bottle equipped with 18ml physiological saline with sterilization treatment. It is best to put a little glass bead in the cone bottleEssenceThen dilute the volume concentration with sterile water to 1 × 10, respectively -3 , 1 × 10 -4 The dilution of the two gradients is painted with a sterilized gun head in the pre-prepared and sterilized selective flat medium with a sterilized gun head and cultivated 48-96h at 30 ° C.From a selective tablet medium to separate the single -bacterial colonies, some of the selected single -bacterial mirror examination judge the purity of the strain (microscope observes the same morphological characteristics).If it is not a colonies, it should be repeatedly separated f...

Embodiment 2

[0070] Example 2 The preparation of liquid fermentation liquid containing grapemine containing grapemine, hypoprosis 11568 liquid fermentation liquid

[0071] (1) Landscape cultivation: Decadence of starchybacteria 11568 is inoculated to the slash medium, and it is cultivated for 48 hours at 40 ° C.The oblique medium used (G / L) is: MGSO 4 0.5, kh 2 PO 4 1.5, CACL 2 0.1, (NH 4 ) 2 So 4 1.5, KCL 0.5, KNO3 1.5, yeast cream 2, orange peel powder 15, agar 20, pH 6.0, 1 × 10 5 PA sterilization 20 min.

[0072] (2) Liquid bottle fermentation: The obtained strain was inoculated at a vaccination of 0.2%(V / V) to the liquid bottle medium, the cultivation temperature was 40.9 ° C, the speed of the bed was 180R / min, and the cultivation time was 48h; the liquid was obtained;Ferry solution.Liquid shake bottle medium (G / L) is: MGSO 4 0.5, kh 2 PO 4 1.5, CACL 2 0.1, (NH 4 ) 2 So 4 1.5, KCL 0.5, KNO 3 1.5, yeast cream 2, orange peel powder 7.5, pH 6.0, 1 × 10 5 PA sterilization 20 min.

[0073] (3)...

Embodiment 3

[0075] Example 3 Preparation of liquid fermentation liquid with liquid fermentation liquid containing grapepelidinase, deercybaidia 11568

[0076] Step 2 steps (1) The trained strain that is cultivated with 0.2%(V / V) is inoculated into a 250ml cone bottle equipped with a liquid medium, and the liquid bottle is fermented.The bed speed is 180 R / min, the fermentation time is 48 h; the liquid fermentation liquid is obtained.Liquid medium formation (G / L): Pomelochide 10, Tenta 胨 10, (NH 4 ) 2 HPO 4 20, NaCL 10, yeast extract 5; pH 7.51, 1 × 10 5 PA sterilization 20 min.

[0077] (3) The composition of the liquid fermentation liquid is determined through the high -efficiency liquid chromatography method (water: methanol = 1: 1), and the test results are figure 1 : The liquid fermentation liquid contains grapefrofidin and grapefruit skin.

[0078] (4) Measure the vitality of the liquid fermentation liquid prepared by the Example 2 of the Example 2 of the Example 2 of the Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com