A kind of tough high-strength epoxy resin potting compound and its preparation method and application

A technology of epoxy resin and potting compound, which is applied in epoxy resin glue, chemical instruments and methods, and other chemical processes, etc. High rigidity and other problems, to solve the cracking of the adhesive layer, avoid excessive curing stress, and increase flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

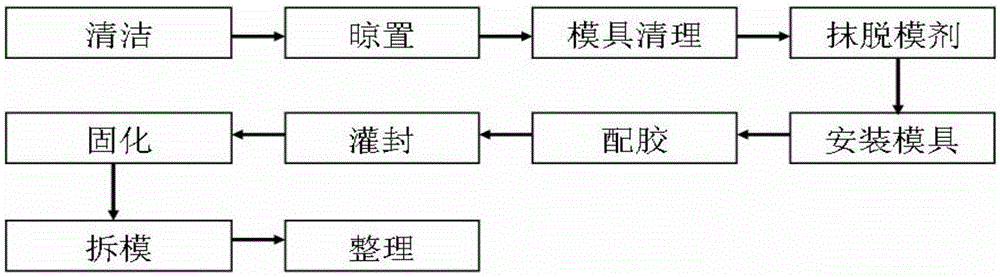

Image

Examples

Embodiment 1

[0028] The tough and high-strength epoxy resin potting compound of this embodiment is made of the following components in parts by mass: 100 parts of E-51 epoxy resin, 15 parts of hexamethylenediamine, T L 20 parts of 1210 liquid polysulfide rubber, 10 parts of PY-30 glycidyl ether.

[0029] Wherein E-51 epoxy resin was purchased from Shanghai Resin Factory Co., Ltd.; T L 1210 liquid polysulfide rubber was purchased from Jinxi Chemical Factory; PY-30 glycidyl ether was purchased from Zhonghao Chenguang Chemical Research Institute Co., Ltd.

[0030] The preparation method of the tough high-strength epoxy resin potting compound in this embodiment is:

[0031] 1) Weigh E-51 epoxy resin, PY-30 glycidyl ether, T L 1210 liquid polysulfide rubber, fully stirred evenly, and then placed in an oven at 62°C for about 50 minutes to prepare rubber material A;

[0032] 2) Take out the compound A and cool it to room temperature, add hexamethylenediamine in proportion, stir well, and place...

Embodiment 2

[0036] The tough and high-strength epoxy resin potting compound of this embodiment is made of the following components in parts by mass: 95 parts of E-51 epoxy resin, 14 parts of hexamethylenediamine, T L 18 parts of 1210 liquid polysulfide rubber, 9 parts of PY-30 glycidyl ether.

[0037] Wherein E-51 epoxy resin was purchased from Shanghai Resin Factory Co., Ltd.; T L 1210 liquid polysulfide rubber was purchased from Jinxi Chemical Factory; PY-30 glycidyl ether was purchased from Zhonghao Chenguang Chemical Research Institute Co., Ltd.

[0038] The preparation method of the tough high-strength epoxy resin potting compound in this embodiment is:

[0039] 1) Weigh E-51 epoxy resin, PY-30 glycidyl ether, T L 1210 liquid polysulfide rubber, fully stirred evenly, and then placed in an oven at 55°C for about 60 minutes to prepare rubber material A;

[0040] 2) Take out the compound A and cool it to room temperature, add hexamethylenediamine in proportion, stir well, and place i...

Embodiment 3

[0044] The tough and high-strength epoxy resin potting compound of this embodiment is made of the following components in parts by mass: 105 parts of E-51 epoxy resin, 16 parts of hexamethylenediamine, T L 22 parts of 1210 liquid polysulfide rubber, 11 parts of PY-30 glycidyl ether.

[0045] Wherein E-51 epoxy resin was purchased from Shanghai Resin Factory Co., Ltd.; T L 1210 liquid polysulfide rubber was purchased from Jinxi Chemical Factory; PY-30 glycidyl ether was purchased from Zhonghao Chenguang Chemical Research Institute Co., Ltd.

[0046] The preparation method of the tough high-strength epoxy resin potting compound in this embodiment is:

[0047] 1) Weigh E-51 epoxy resin, PY-30 glycidyl ether, T L 1210 liquid polysulfide rubber, fully stirred evenly, and then placed in an oven at 65°C for about 45 minutes to prepare rubber material A;

[0048] 2) Take out the compound A and cool it to room temperature, add hexamethylenediamine, stir well, and place it under vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com