Preparation method of six-leaf porous hollow staple fibers spun from renewable polyester bottle flakes

A technology of regenerated polyester and short fibers, which is applied in the field of synthetic fiber processing, to achieve the effects of improved degree of irregularity and moisture absorption and water absorption, good resilience, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

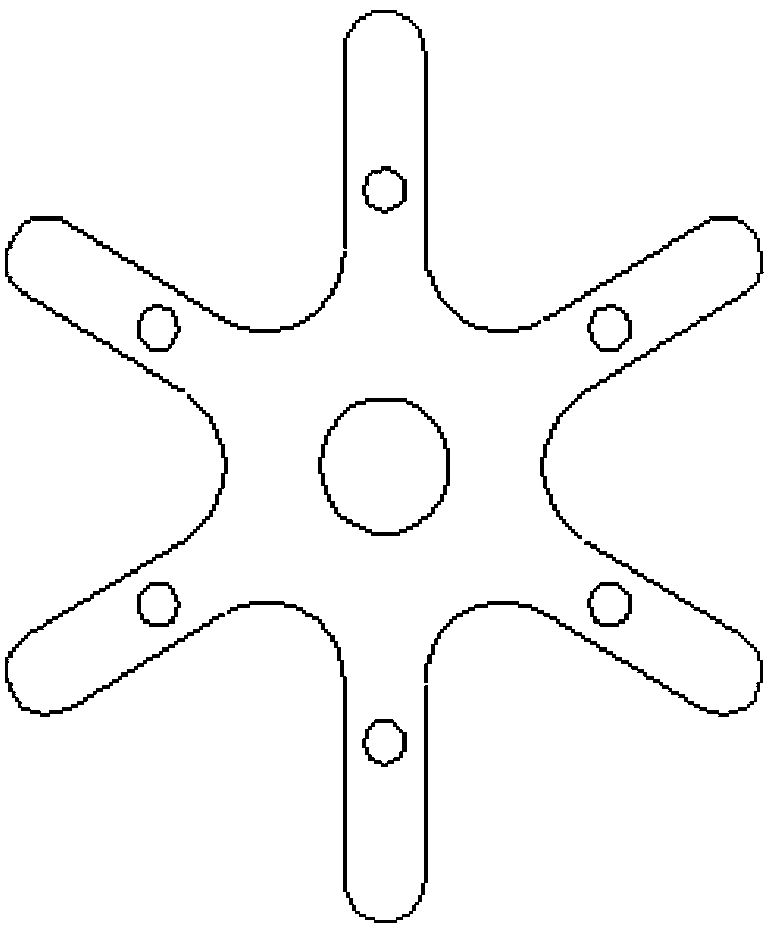

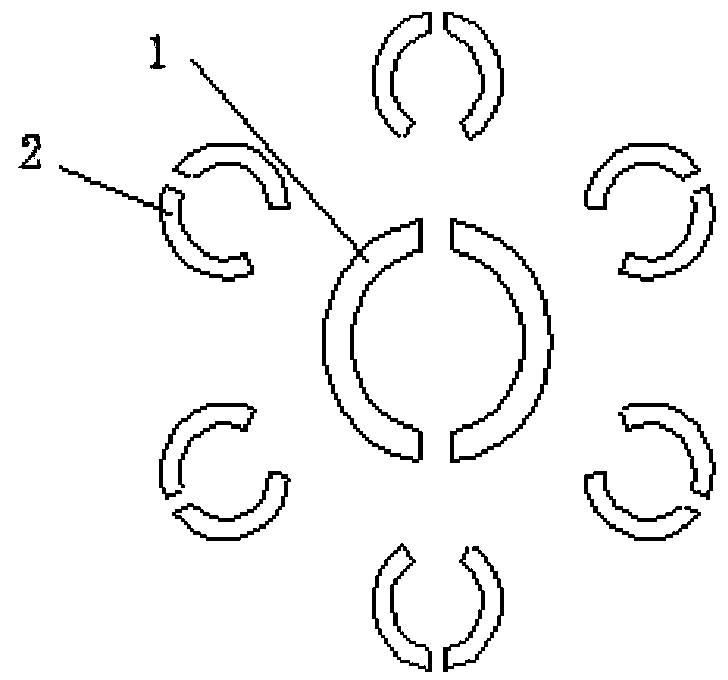

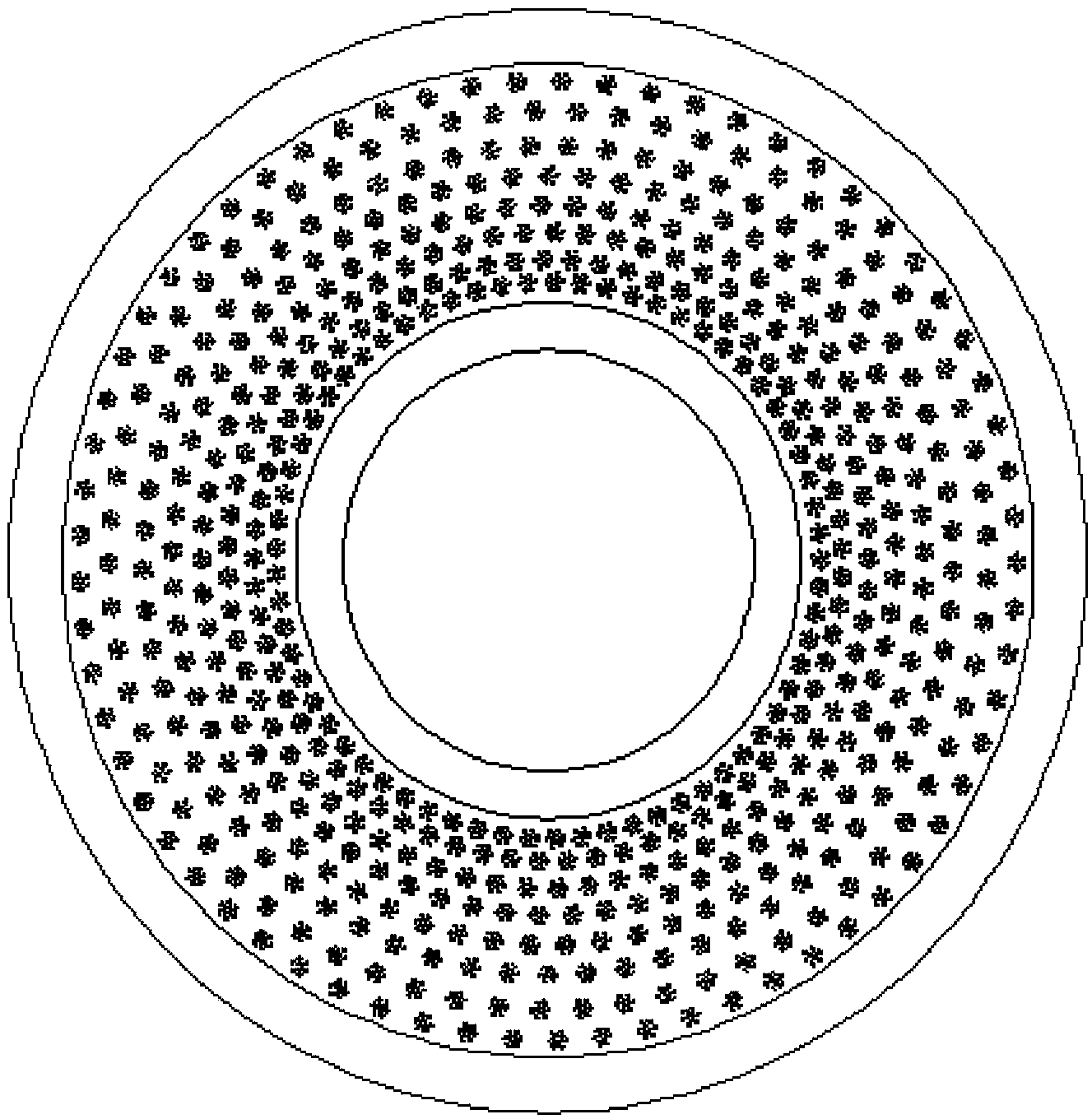

[0028] A kind of regenerated polyester bottle flakes of the present invention spins the preparation method of six leaf porous hollow short fibers and the spinneret used thereof, realizes by following steps: choose the regenerated polyester bottle flakes that viscosity is 0.58dl / g as The spinning raw material is sent to a vacuum drum dryer for drying, the drying temperature is set at 150°C, and dried for 10 hours, so that the moisture content in the spinning raw material is less than 85PPM; the dried spinning raw material is fed into the melt spinning equipment for Melt spinning, the molten spinning raw material is extruded into the spinning box through a screw extruder, and is sprayed out from the spinneret holes of the six-blade porous hollow spinneret to form primary fibers; Cooling, winding, bundling, drafting, crimping, oiling, relaxing heat setting, cutting, and packaging processes to produce six-leaf 7-hole hollow staple fibers with a fineness of 20.00dtex. During the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com