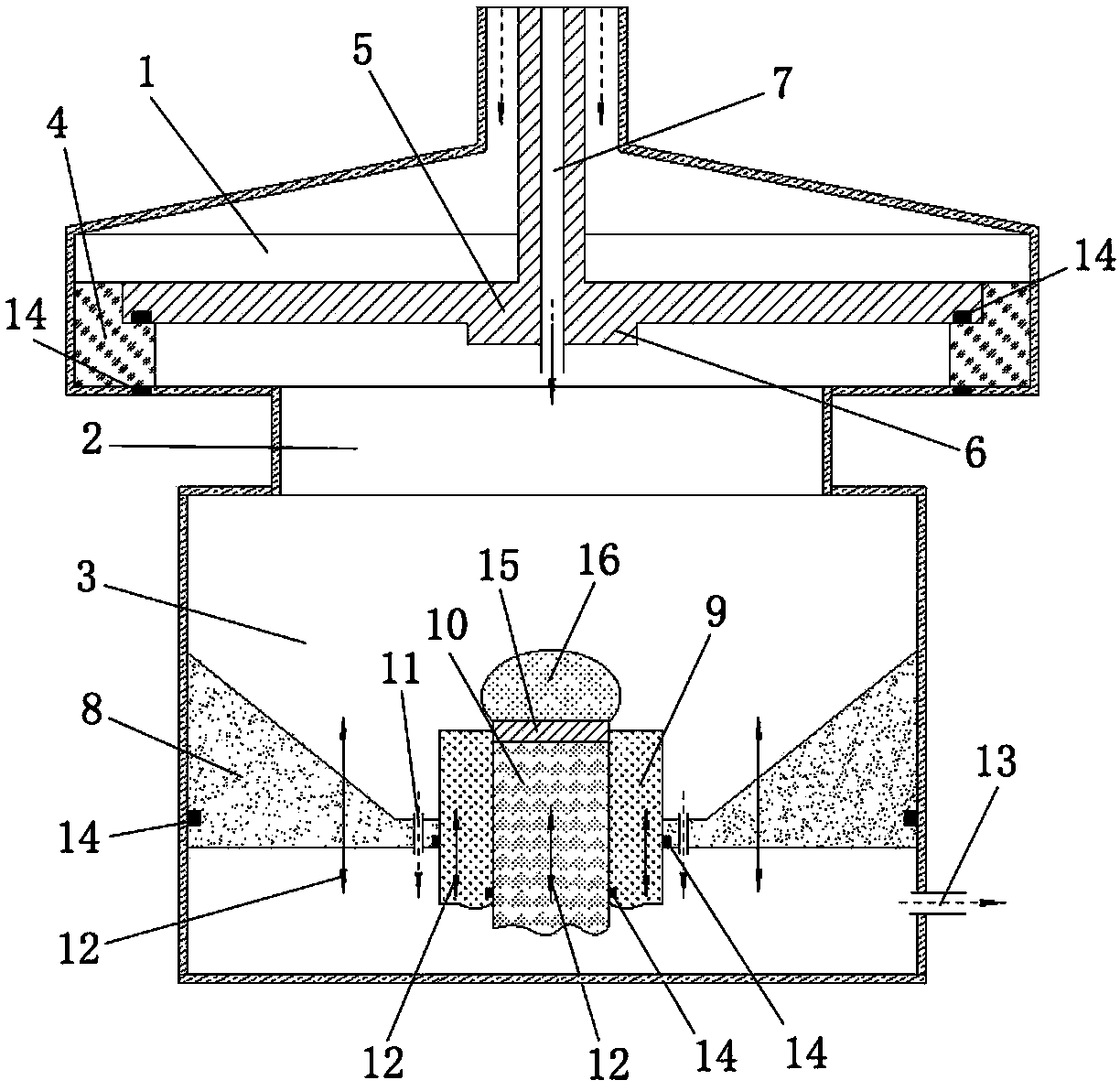

High-power microwave plasma reaction unit for chemical vapor deposition of diamond films

A technology of chemical vapor deposition and high-power microwave, which is applied in the direction of gaseous chemical plating, electrical components, metal material coating technology, etc., can solve the problems of energy dispersion, poor focusing ability, lack of adjustment mechanism, etc., to achieve optimal adjustment, improve Focusing ability, effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Use a single crystal silicon wafer with a diameter of 65 mm and a thickness of 3 mm as the material of the substrate 15. First, the deposition surface of the circular substrate 15 is uniformly ground with diamond powder with a particle size of 5 μm, and then deionized water and acetone are used respectively Clean the surface of the substrate 15 ultrasonically, dry it with hot air, and place it on the top surface of the cylindrical abutment 10;

[0040] 2. Close the vacuum reaction chamber, and use a vacuum pump to pump the pressure in the reaction chamber below 1Pa;

[0041] 3. Turn on the circulating water cooling system and supply cooling water to each part of the device;

[0042] 4. In the reaction chamber of the device, the hydrogen gas with a flow rate of 600 sccm is introduced, and the pressure in the reaction chamber is adjusted to 2kPa;

[0043] 5. After setting the power of the microwave source with a frequency of 2.45 GHz to 2 kW, turn it on, and generate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com