A method for continuously leaching scheelite

A scheelite and leaching technology, applied in the field of continuous scheelite leaching, can solve the problems of high local temperature, affecting leaching, slurry agglomeration, etc., and achieve efficient decomposition, stable decomposition, and pressure reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 A kind of method for continuously decomposing scheelite

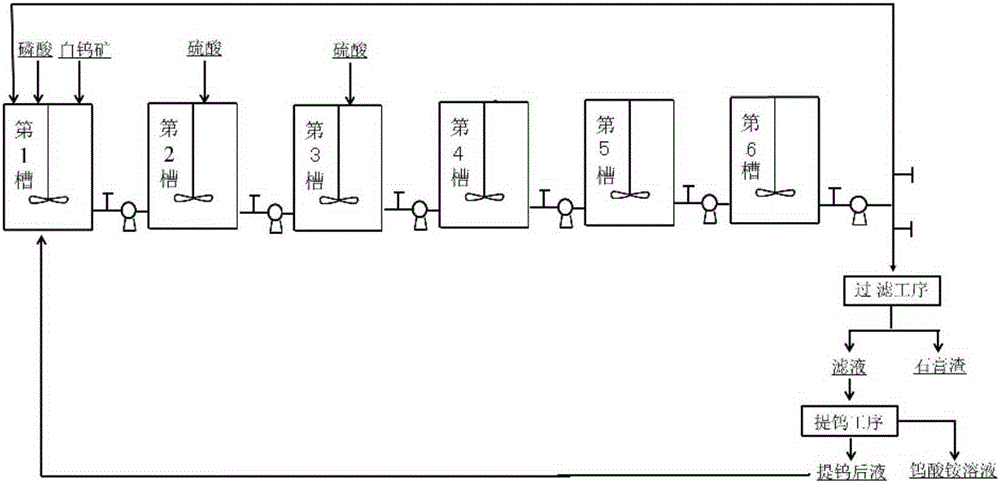

[0026] Such as figure 1 As shown, a decomposition system with 6 tanks connected in series is used to continuously decompose scheelite. Among them, the first tank is a pre-reaction tank, the second and third tanks are phosphoric acid regeneration tanks, and the fourth, fifth and sixth tanks are aging desulfurization tanks. groove.

[0027] WO in the scheelite 3 The mass percentage is 64.7%, and the particle size passes through a 50-mesh sieve.

[0028] A method for continuously decomposing scheelite, comprising the steps of:

[0029] 1) Add scheelite powder into the phosphoric acid solution in the pre-reaction tank 1, and enter the phosphoric acid regeneration tank after reacting for 3-5 hours;

[0030] The phosphoric acid solution in the described pre-reaction tank 1 is converted into P 2 o 5 In terms of concentration, the concentration is 15%;

[0031] The mass volume ratio of the scheelite p...

Embodiment 2

[0038] Embodiment 2 A kind of method for continuously decomposing scheelite

[0039] Decompose scheelite according to the method of embodiment 1, difference is:

[0040] 1) The scheelite WO 3 The mass percentage is 52.6%, and the particle size is 50 mesh sieves;

[0041] 2) the phosphoric acid solution in the described pre-reaction tank 1 is converted into P 2 o 5 In terms of concentration, the concentration is 30%;

[0042] 3) The mass volume ratio of the scheelite powder to the phosphoric acid solution is 1:5 (g / mL);

[0043] 4) The sulfate radical concentration is controlled at 30g / L in the phosphoric acid regeneration tank;

[0044] 5) The volume of the reflux pulp in the aging desulfurization tank accounts for 2 / 3 of the total pulp volume;

[0045] 6) The temperature of the entire reaction system is at 100°C;

[0046] 7) Extract tungsten from the leach solution through D314 resin.

[0047] After testing, the WO in the leachate obtained by filtration 3 The concent...

Embodiment 3

[0048] Embodiment 3 A kind of method for continuously decomposing scheelite

[0049] Decompose scheelite according to the method of embodiment 1, difference is:

[0050] 1) The scheelite WO 3 The mass percentage is 46.1%, and the particle size is 50 mesh sieves;

[0051] 2) the phosphoric acid solution in the described pre-reaction tank 1 is converted into P2 o 5 In terms of concentration, the concentration is 30%;

[0052] 3) The mass volume ratio of the scheelite powder to the phosphoric acid solution is 1:2 (g / mL);

[0053] 4) The sulfate radical concentration is controlled at 50g / L in the phosphoric acid regeneration tank;

[0054] 5) The volume of the reflux pulp in the aging desulfurization tank accounts for 4 / 5 of the total pulp volume;

[0055] 6) The temperature of the entire reaction system is at 80°C;

[0056] After testing, the WO in the leachate obtained by filtration 3 The concentration is 231.3g / L, the adsorption rate is 99.2%, and the decomposition rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com