Regenerated HIPS environmental-friendly modified material and preparation method thereof

A modified material and environmentally friendly technology, applied in the field of recycling of HIPS recycled materials, can solve the problems of a large amount of smoke and corrosive gases, and achieve the effects of high impact resistance, simple preparation process, and stable thermal deformation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

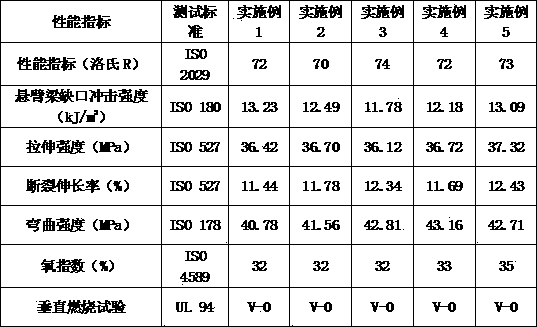

Examples

Embodiment 1

[0060] A recycled HIPS environmentally friendly modified material, consisting of the following substances by weight:

[0061] HIPS recycled material 100 copies

[0062] Toughener 3 parts

[0063] Flame retardant 16 parts

[0064] Flame retardant synergist 0.5 parts

[0065] Impact modifier 10 parts

[0066] Antioxidant 2 parts

[0067] 2 parts of coupling agent

[0068] Lubricant 5 parts

[0069] Stabilizer 2 parts,

[0070] Wherein, the flame retardant is composed of a composite flame retardant of ammonium polyphosphate, magnesium hydroxide and zinc borate mixed with montmorillonite-hexadecyltrimethylammonium bromide; the flame retardant synergist is A mixture of hydrotalcite chemicals and red phosphorus masterbatch in a mass ratio of 1.8:1, the impact modifier is waste TPR shoe sole material, and the particle diameter of the waste TPR shoe sole material is 3-8 μm. When the mass of hydrotalcite-like chemicals and red phosphorus masterbatch is 2:1, the flame retardant ...

Embodiment 2

[0085] A recycled HIPS environmentally friendly modified material, consisting of the following substances by weight:

[0086] HIPS recycled material 100 copies

[0087] Toughener 6 parts

[0088] Flame retardant 20 parts

[0089] Flame retardant synergist 0.5 parts

[0090] Impact modifier 10 parts

[0091] Antioxidant 2 parts

[0092] 1 part coupling agent

[0093] Lubricant 2 parts

[0094] Stabilizer 5 parts,

[0095] Wherein, the flame retardant is composed of a composite flame retardant of ammonium polyphosphate, magnesium hydroxide and zinc borate mixed with montmorillonite-hexadecyltrimethylammonium bromide; the flame retardant synergist is A mixture of hydrotalcite chemicals and red phosphorus masterbatch at a mass ratio of 1.8-2:1, the impact modifier is waste TPR shoe sole material, and the particle size of the waste TPR shoe sole material is 3-8 μm .

[0096] When the mass of hydrotalcite-like chemicals and red phosphorus masterbatch is 2:1, the flame retar...

Embodiment 3

[0111] A recycled HIPS environmentally friendly modified material, consisting of the following substances by weight:

[0112] HIPS recycled material 100 copies

[0113] Toughener 4 parts

[0114] Flame retardant 18 parts

[0115] Flame retardant synergist 0.8 parts

[0116] Impact modifier 11 parts

[0117] Antioxidant 2 parts

[0118] 3 parts of coupling agent

[0119] Lubricant 4 parts

[0120] 3 parts of stabilizer,

[0121] Wherein, the flame retardant is composed of a composite flame retardant of ammonium polyphosphate, magnesium hydroxide and zinc borate mixed with montmorillonite-hexadecyltrimethylammonium bromide; the flame retardant synergist is A mixture of hydrotalcite chemicals and red phosphorus masterbatch at a mass ratio of 1.8-2:1, the impact modifier is waste TPR shoe sole material, and the particle size of the waste TPR shoe sole material is 3-8 μm .

[0122] When the mass of hydrotalcite-like chemicals and red phosphorus masterbatch is 2:1, the flam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com