Microbial fuel cell based method for treatment and detection of chromium-containing electroplating wastewater

A fuel cell and treatment method technology, applied in biochemical fuel cells, biological water/sewage treatment, metallurgical wastewater treatment, etc., can solve the problems of toxic sludge, high energy consumption, high chemical reagents, etc., and achieve no pollution, easy removal, The effect of avoiding toxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

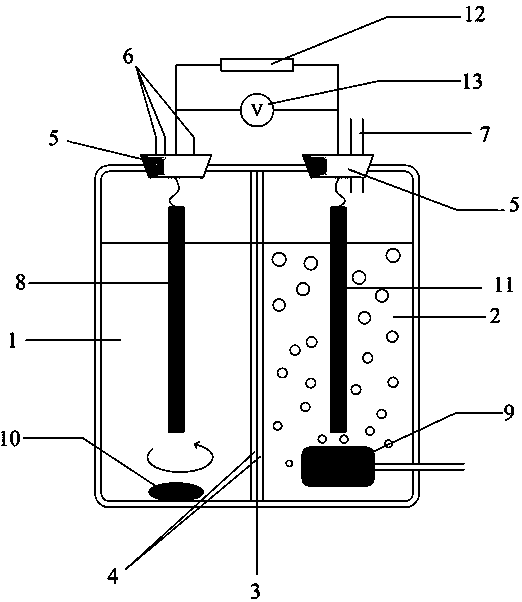

[0034] Inject 50ml of anaerobic sludge and 150ml of sodium acetate solution into the anode chamber of the dual-chamber microbial fuel cell to inoculate microorganisms, inject 200ml of catholyte into the cathode chamber, and connect a 1000Ω resistor to the anode and cathode to form a closed loop. The battery is kept at a constant temperature of 35°C React in the box, inject 80mg of sodium acetate into the anode chamber every day until the output voltage is stable at 240-260mV, the composition of the catholyte: KH 2 PO 4 13.60g / l, NaCl 11.70g / l, NaOH 2.33g / l;

[0035] Replace the anode chamber solution with 200ml anolyte that removes oxygen, replace the catholyte with chromium-containing electroplating wastewater, use graphite paper as the cathode material, and use carbon felt as the anode material. The composition of the anolyte: KH 2 PO 4 13.60g / l, CH 3 COONa is 1.00g / l, NaCl is 11.70g / l, NaOH is 1.164g / l, NH 4 Cl is 0.454g / l, MgCl 2 ·6H 2 O is 0.165g / l, FeCl 3 ·6H 2 O...

Embodiment 2

[0042] Inject 50ml of anaerobic sludge and 150ml of sodium acetate solution into the anode chamber of the dual-chamber microbial fuel cell to inoculate microorganisms, inject 200ml of catholyte into the cathode chamber, and connect a 1000Ω resistor to the anode and cathode to form a closed loop. The battery is kept at a constant temperature of 35°C React in the box, inject 80mg of sodium acetate into the anode chamber every day until the output voltage is stable at 240-260mV, the composition of the catholyte: KH 2 PO 4 13.60g / l, NaCl 11.70g / l, NaOH 2.33g / l;

[0043] Replace the anode chamber solution with 200ml of anolyte that removes oxygen, replace the catholyte with chromium-containing electroplating wastewater, use carbon felt as the cathode material, and use carbon felt as the anode material. The composition of the anolyte: KH 2 PO 4 13.60g / l, CH 3 COONa is 1.00g / l, NaCl is 11.70g / l, NaOH is 1.164g / l, NH 4 Cl is 0.454g / l, MgCl 2 ·6H 2 O is 0.165g / l, FeCl 3 ·6H 2 O...

Embodiment 3

[0050] Inject 50ml of anaerobic sludge and 150ml of sodium acetate solution into the anode chamber of the dual-chamber microbial fuel cell to inoculate microorganisms, inject 200ml of catholyte into the cathode chamber, and connect a 1000Ω resistor to the anode and cathode to form a closed loop. The battery is kept at a constant temperature of 35°C React in the box, inject 80mg of sodium acetate into the anode chamber every day until the output voltage is stable at 240-260mV, the composition of the catholyte: KH 2 PO 413.60g / l, NaCl 11.70g / l, NaOH 2.33g / l;

[0051] Replace the anode chamber solution with 200ml of anolyte that removes oxygen, replace the catholyte with chromium-containing electroplating wastewater, use carbon paper as the cathode material, and use carbon felt as the anode material. The composition of the anolyte: KH 2 PO 4 13.60g / l, CH 3 COONa is 1.00g / l, NaCl is 11.70g / l, NaOH is 1.164g / l, NH 4 Cl is 0.454g / l, MgCl 2 ·6H 2 O is 0.165g / l, FeCl 3 ·6H 2 O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum power density | aaaaa | aaaaa |

| Internal resistance | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com