Method and Device for Measuring Bulk Conductivity of Space Dielectric Material under Temperature Gradient

A technology of dielectric materials and temperature gradients, applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of unreported test devices and research blanks, so as to improve test efficiency, test results Accurate, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

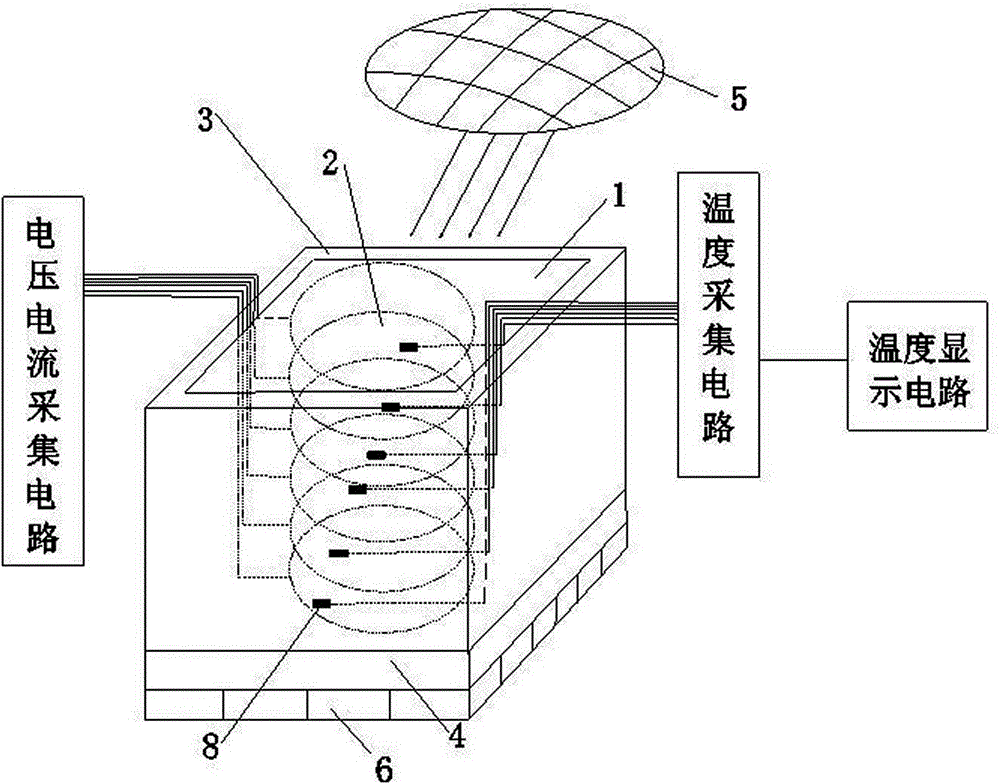

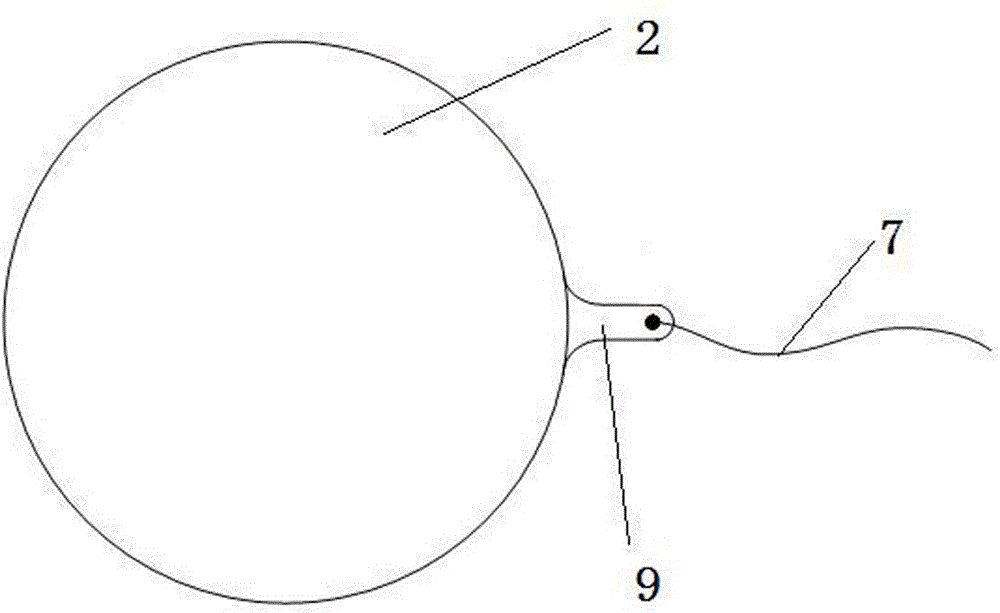

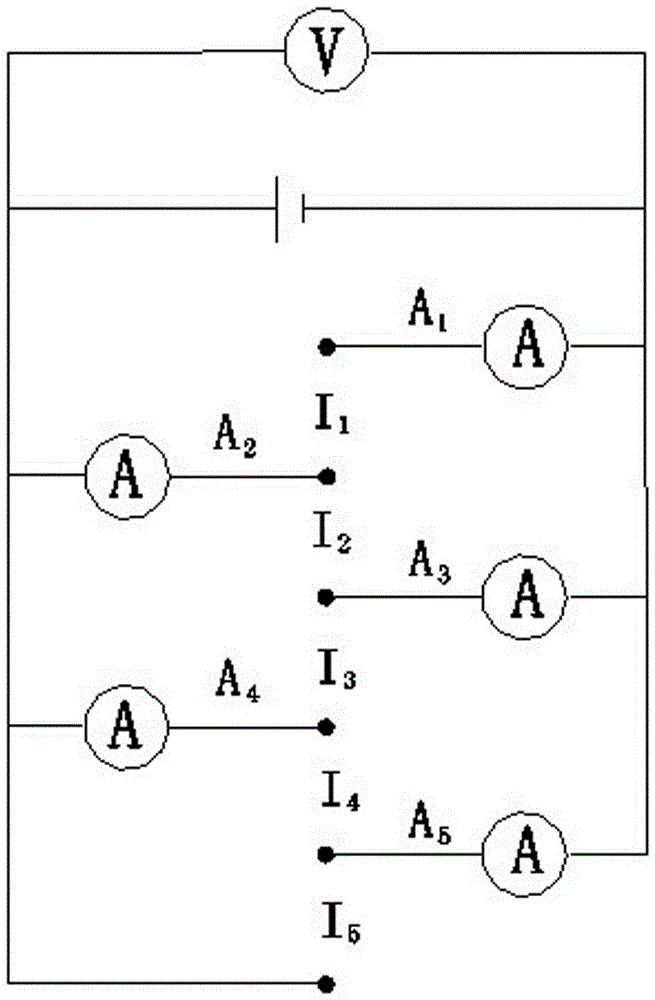

[0028] Such as figure 1 As shown, the measuring device for the lower body conductivity of the star with a dielectric material temperature gradient includes a heat source 5, a temperature acquisition device, a voltage and current acquisition circuit, and a multilayer circuit board processing technology that is arranged in the dielectric material 1 along the thickness direction 6. layers of metal. The measured dielectric material 1 is one of epoxy resin, polyimide or polytetrafluoroethylene or one of the modified dielectric materials. The modified dielectric material is mainly obtained by doping glass powder, glass cloth, etc. The new dielectric material formed by the material, the measured dielectric material 1 is made into a cube shape. Each metal layer is provided with a metal sheet 2 with an area of S, each metal sheet 2 is a circular copper sheet of the same size, the center of the metal sheet 2 is on a straight line, and the diameter of the metal sheet 2 is close to the...

Embodiment 2

[0036] Figure 4 Another embodiment of the present invention is given. The difference between the measurement device for the bulk conductivity of the star dielectric material 1 under temperature gradient and the embodiment 1 is that the number of metal sheets 2 on the metal layer of the dielectric material 1 to be measured is More than one metal sheet 2 adjacent up and down has the same structure and corresponding positions. Such as Figure 4 As shown, each layer of metal layer is given by Metal sheets 2 arranged in an array. The temperature sensor 8 is arranged in the measured dielectric material 1 on each metal sheet 2 . This embodiment is mainly aimed at the situation that the temperature is distributed three-dimensionally in the medium when the distribution of the heat source is not uniform or the boundary insulation condition is not symmetrical. That is, by arranging a plurality of metal sheets 2 in each layer, the three-dimensional distribution result of the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com